Transcritical carbon dioxide heat pump device

A technology of carbon dioxide and heat pump devices, which is applied in the field of heat pump systems, can solve the problems of lack of oil in compressors, poor oil return fluidity, and singleness, and achieve the effects of high oil return efficiency, safe operation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

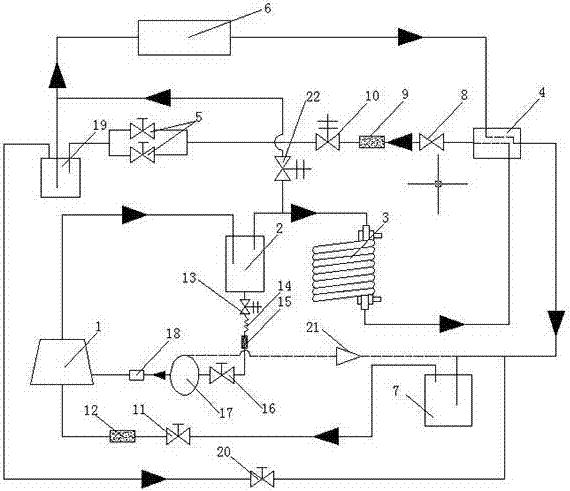

[0025] Example: such as figure 1 As shown, a transcritical carbon dioxide heat pump device includes a compressor 1, a high-pressure oil separator 2, a gas cooler 3, a regenerator 4, and two electronic expansion valves connected in parallel in the carbon dioxide circulation pipeline according to the flow direction of carbon dioxide. A throttling device 5, an air-cooled evaporator 6, and a gas-liquid separator 7 are formed. The compressor 1 has a carbon dioxide inlet and an oil inlet, and the high-pressure oil separator 2 has a carbon dioxide inlet and an oil outlet. The gas cooler has an inlet and outlet of carbon dioxide and heat exchange water, the regenerator 4 has an inlet and outlet of carbon dioxide, the air-cooled evaporator 6 has an inlet and outlet of carbon dioxide, and an inlet and outlet of air, and the gas-liquid separator 7 has Carbon dioxide inlet and outlet, the carbon dioxide outlet of the gas-liquid separator 7 is connected to the carbon dioxide inlet of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com