Internal combustion engine control device and internal combustion engine control method

A control device and internal combustion engine technology, applied in engine control, internal combustion piston engine, electrical control, etc., can solve problems such as overcurrent, WGV opening deviation, and inability to control the opening and closing state of WGV, so as to achieve reliable full-close action and prevent abnormalities overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

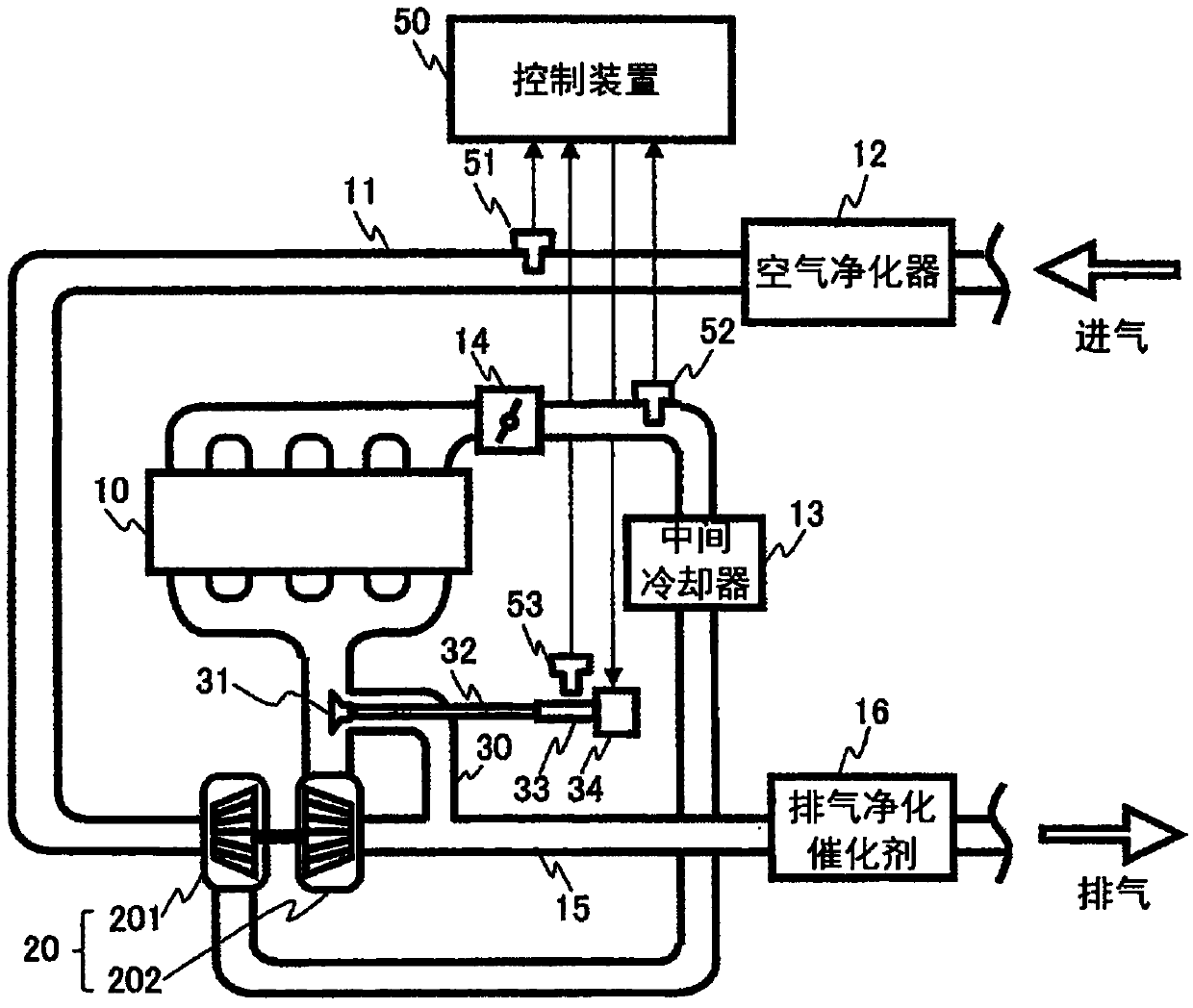

[0043] figure 1 It is a system configuration diagram of an engine to which the control device for an internal combustion engine according to Embodiment 1 of the present invention is applied. exist figure 1 Among them, an air cleaner 12 is installed at the inlet of the intake passage 11 of the engine 10 . On the downstream side of the air cleaner 12, an air flow sensor 51 for detecting the amount of intake air is provided.

[0044] The turbocharger 20 is provided on the downstream side of the airflow sensor 51 . The turbocharger 20 includes a compressor 201 and a turbine 202 . The compressor 201 and the turbine 202 are integrally connected by a connecting shaft. The compressor 201 is rotationally driven by energy of exhaust gas input to the turbine 202 .

[0045] Furthermore, an intercooler 13 for cooling the compressed air is disposed further downstream of the compressor 201 . A throttle valve 14 is disposed further downstream of the intercooler 13 .

[0046] Furthermor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com