Parallel type gas water heater condensation heat exchanger

A technology for gas water heaters and condensing heat exchangers, which is used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of no fixation of bellows, hidden dangers of resonance, and long bellows, and achieve a wide range of water flow. , The effect of small resistance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the patent of the present invention will be further described.

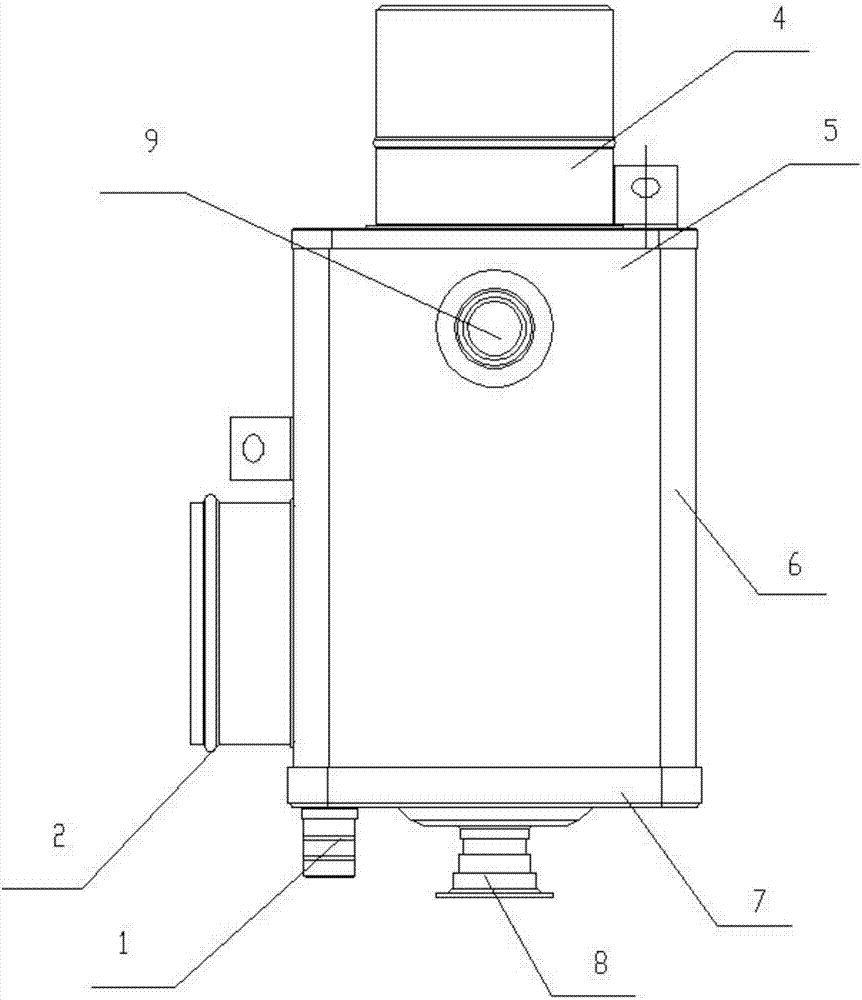

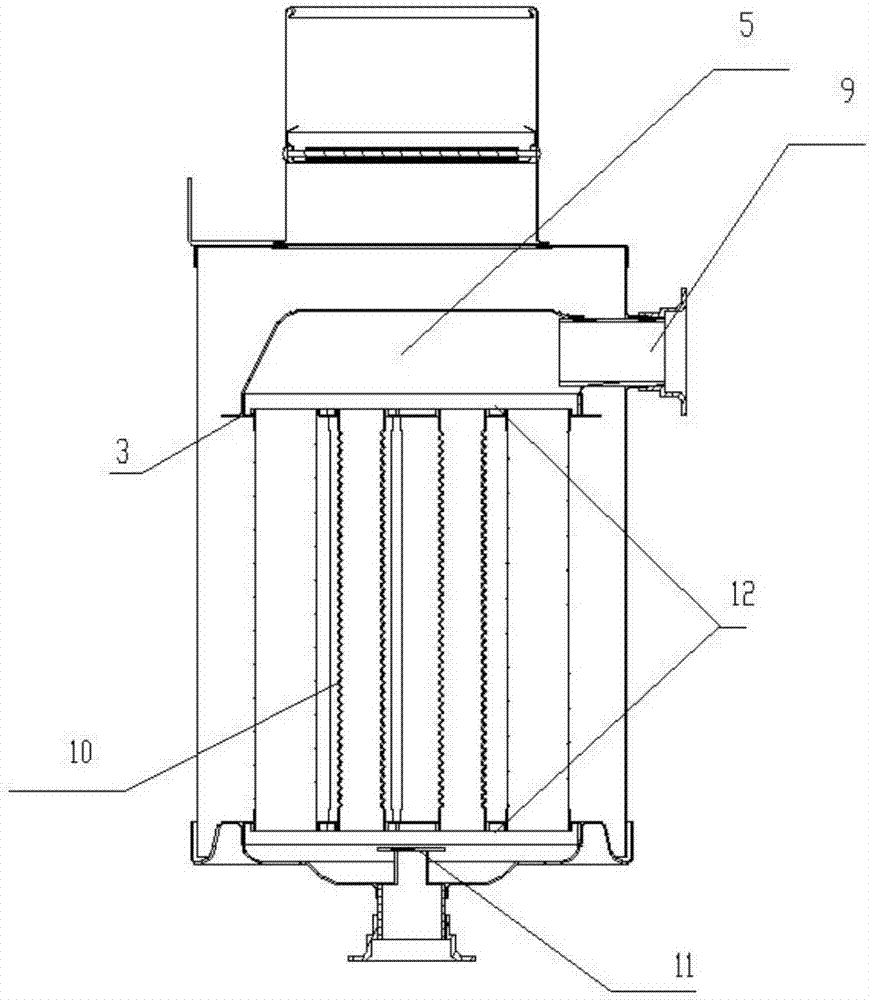

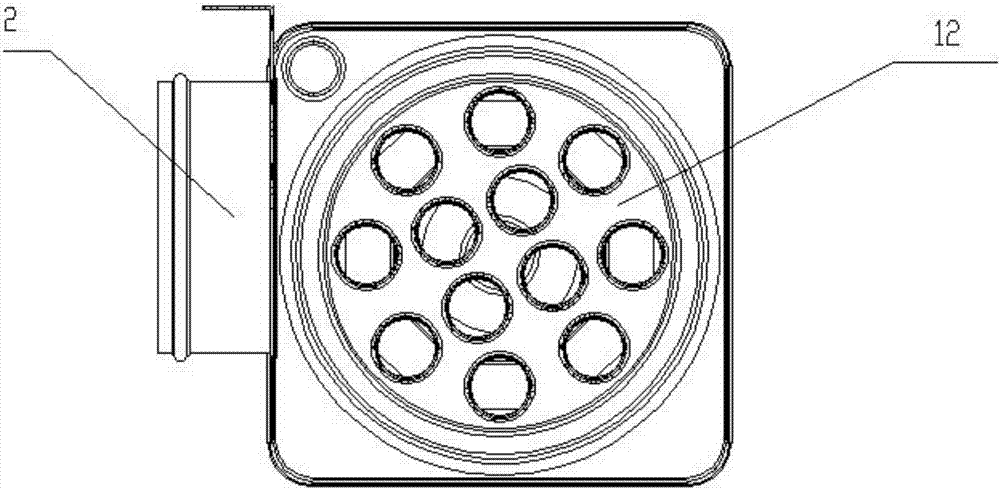

[0017] Such as Figure 1-3 As shown, the gas water heater condensing tube heat exchanger with parallel structure of the present invention includes a cavity 6 and several bellows 10 arranged in parallel in the cavity 6, and bellows fixing plates 12 are arranged at both ends of the bellows 10 , the upper and lower sides of the cavity 6 are provided with end caps, and the end caps and the fixed plate of the bellows form two small chambers 5 and 7 for water collection and water separation. The small chamber 7 at the lower end is provided with a water guide device 11 and a condensed water collection device. It is arranged on the wall of the chamber 6, and the lower end is connected with a condensed water outlet, and the outlet is provided with a condensed water joint 1; the chamber 6 has a flue gas import / export inlet and outlet, and the chamber is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com