Control method of reversal compressing power assisting starting equipment

A technology of a starting device and a control method, which is applied to a fluid-driven starting device, an engine starting, an engine motor starting, etc., can solve the problems of small starting torque, difficult to rotate through the compression stroke, and large compression stroke resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

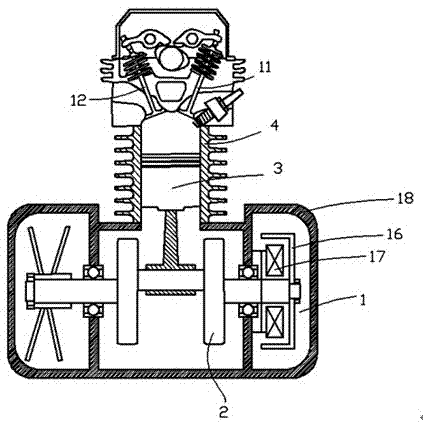

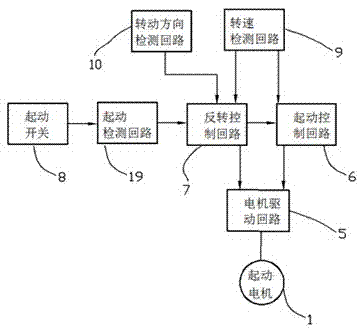

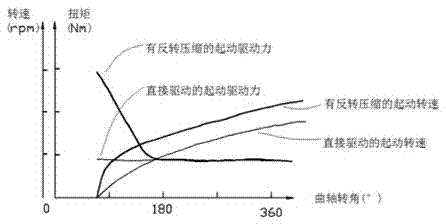

[0013] The control method of the reverse compression booster starting device of the present invention adopts the starter motor that makes the crankshaft forward and reverse, the first detection mechanism that detects the rotation direction of the crankshaft, the second detection mechanism and the control mechanism that detects the crankshaft speed; When starting, firstly drive the engine in reverse, compress the gas in the cylinder, then control the crankshaft to start the engine, and use the pressure of the compressed gas in the cylinder to increase the initial driving force of the crankshaft when starting. The second detection mechanism for detecting the crankshaft rotation speed judges that the engine reverse rotation compressed gas has obtained a set pressure to generate auxiliary dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com