Preparation method of vanadium-titanium magnetite oxide pellets for shaft furnace

A technology of vanadium titanomagnetite and oxidizing pellets is applied in the field of metallurgy and can solve the problems of difficulty in pelletizing all-vanadium ilmenite concentrates and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

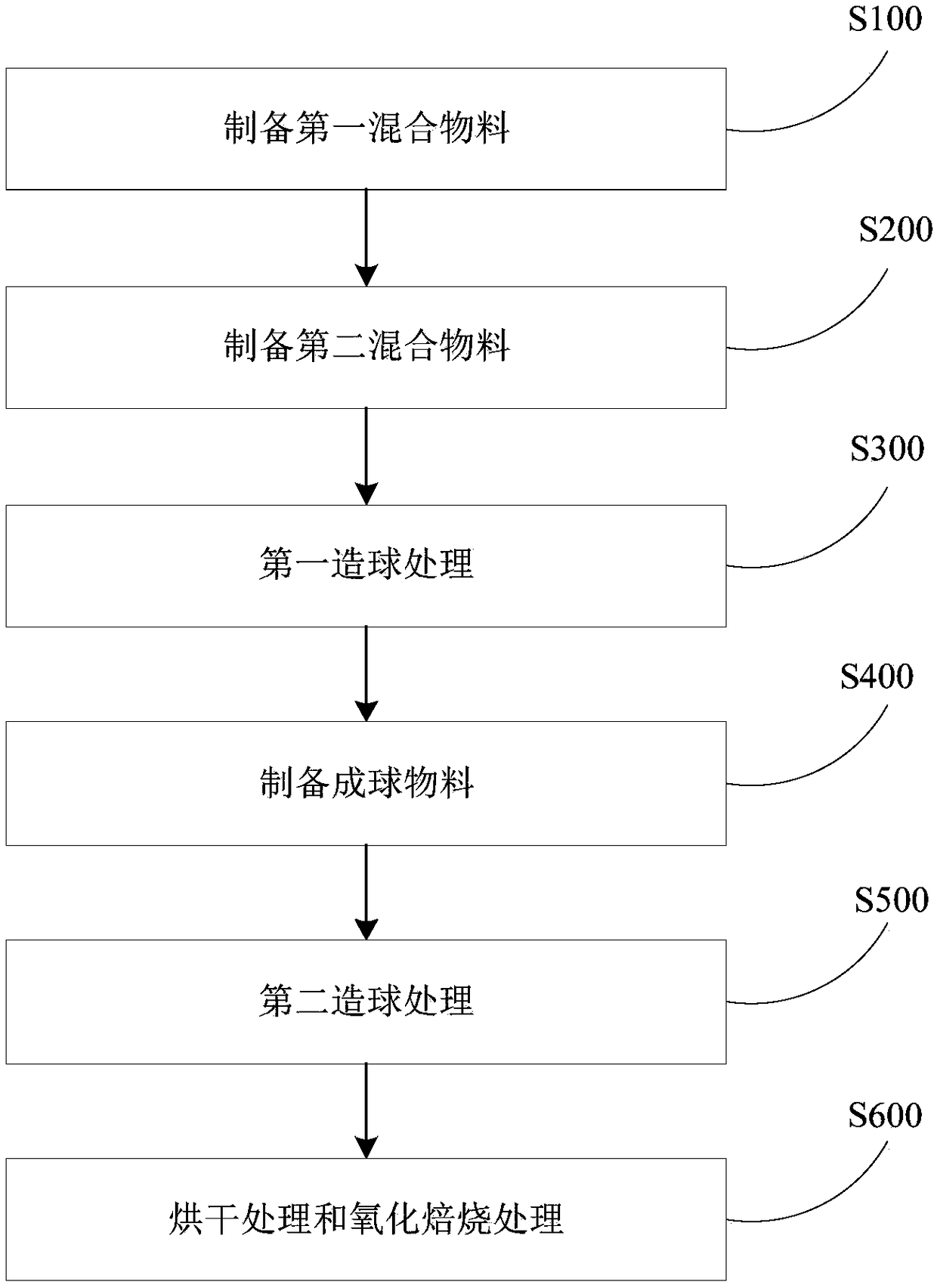

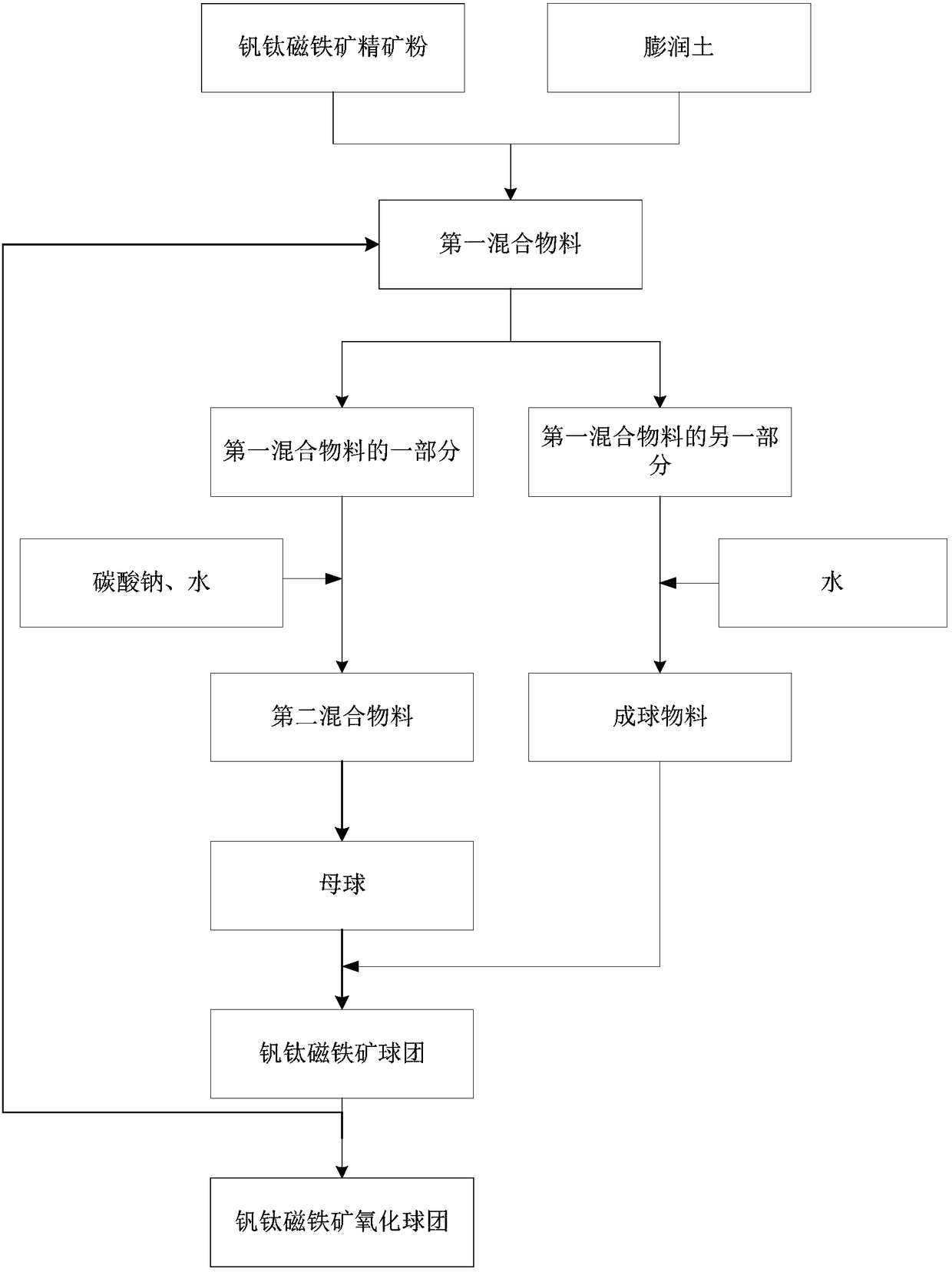

[0029] According to one aspect of the present invention, the present invention proposes a preparation method of vanadium titanomagnetite oxidized pellets for shaft furnace. According to an embodiment of the present invention, the method includes:

[0030] Mixing vanadium titanomagnetite concentrate powder and bentonite to obtain a first mixed material;

[0031] mixing a portion of the first mixture with sodium carbonate and water to obtain a second mixture;

[0032] subjecting the second mixed material to a first pelletizing process to obtain a cue ball;

[0033] Mixing another part of the first mixed material with water to obtain a pelletized material;

[0034] Mixing the cue ball with the pelletizing material and performing a second pelletizing process, so that the pelletizing material wraps the cue ball, so as to obtain vanadium titanomagnetite pellets; and

[0035] The vanadium titanomagnetite pellets are dried and oxidatively roasted to obtain vanadium titanomagnetite o...

Embodiment 1

[0076] 1. Take 10Kg of vanadium titanomagnetite concentrate powder, analyze its composition and particle size, the results are shown in Table 1 and Table 2, and the water content is 0.

[0077] Table 1 Main components / wt% of vanadium titanomagnetite concentrate powder

[0078] TFe

FeO

V 2 O 5

TiO 2

SiO 2

CaO

MgO

Al 2 O 3

S

P

57.22

27.5

0.498

7.77

1.57

1.01

1.00

2.09

0.049

0.058

[0079] Table 2 Particle size distribution of vanadium titanomagnetite concentrate powder

[0080] Grain size / mm

+0.15

-0.15-+0.10

-0.10-+0.074

-0.074-+0.045

-0.074

-0.045

Content / weight%

0.8

2.4

17.6

48.7

79.2

30.5

[0081] Take 0.12Kg of bentonite (the amount added is 1.2% by weight of the mass of vanadium titanomagnetite), and its main components are shown in Table 3.

[0082] Table 3 Main components / wt% of bentonite

[0083] ...

Embodiment 2

[0093] 1. Take 10Kg of vanadium titanomagnetite concentrate powder, analyze its composition and particle size, the results are shown in Table 5 and Table 6, and the water content is 0.

[0094] Table 5 Main components / wt% of vanadium titanomagnetite concentrate powder

[0095] TFe

FeO

V 2 o 5

TiO 2

SiO 2

CaO

MgO

Al 2 O 3

S

P

67.29

27.5

0.546

1.47

1.57

0.66

0.51

0.83

0.001

0.006

[0096] Table 6 Particle size distribution of vanadium titanomagnetite concentrate powder

[0097] Grain size / mm

+0.15

-0.15~+0.10

-0.10~+0.074

-0.074-+0.045

-0.074

-0.045

Content / weight%

2.04

4.28

3.35

42.00

90.33

48.33

[0098] Take 0.12Kg of bentonite (the amount added is 1.2% by weight of the mass of vanadium titanomagnetite), and its main components are shown in Table 7.

[0099] Table 7 Main components / wt% of bentonite

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com