Derailment-prevention auxiliary device of sintering machine trolley

An auxiliary device and machine trolley technology, which is used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of sintering machine trolleys falling off lanes, etc., and achieve the effect of avoiding fault expansion and preventing trolleys from falling off lanes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

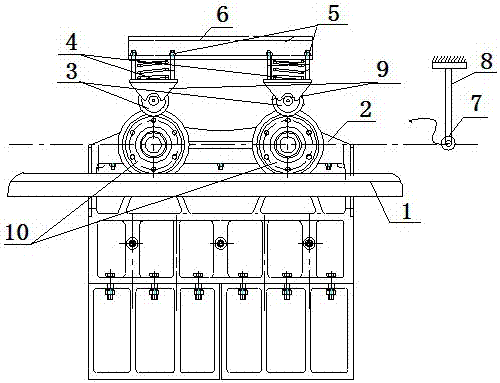

[0008] According to the attached figure 1 To illustrate this example:

[0009] Such as figure 1 As shown in the figure, an anti-fall auxiliary device for a trolley of a sintering machine includes a return lane 1, a trolley 2 and a trolley wheel (10). On both sides of the tail return lane, the two pressure rollers 3 are respectively installed on the crossbeam 6 through the pressure roller base 9 and the adjustment bolt 5, and the spring 4 is installed between the pressure roller base 9 and the crossbeam 6, and its preload is adjusted through the adjustment bolt 5 Force, install limit switch 7 by support 8 on the two trolley wheelbase positions of return track trolley 2 running direction.

[0010] The anti-falling auxiliary device is installed directly above the position of the tail return lane 1 of the sintering machine, and the crossbeam 6 is set up with a bracket, and is symmetrically installed on both sides of the tail return lane, and it is just coming from the curved tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com