Parabolic Motion Testers and Tester Systems

A technology of parabolic movement and experimental equipment, which is applied in the direction of instruments, teaching models, educational appliances, etc., can solve problems such as experimental errors, experimental failures, and complicated operation steps, and achieve the effects of strong intuitiveness, improved teaching effect, and simple and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

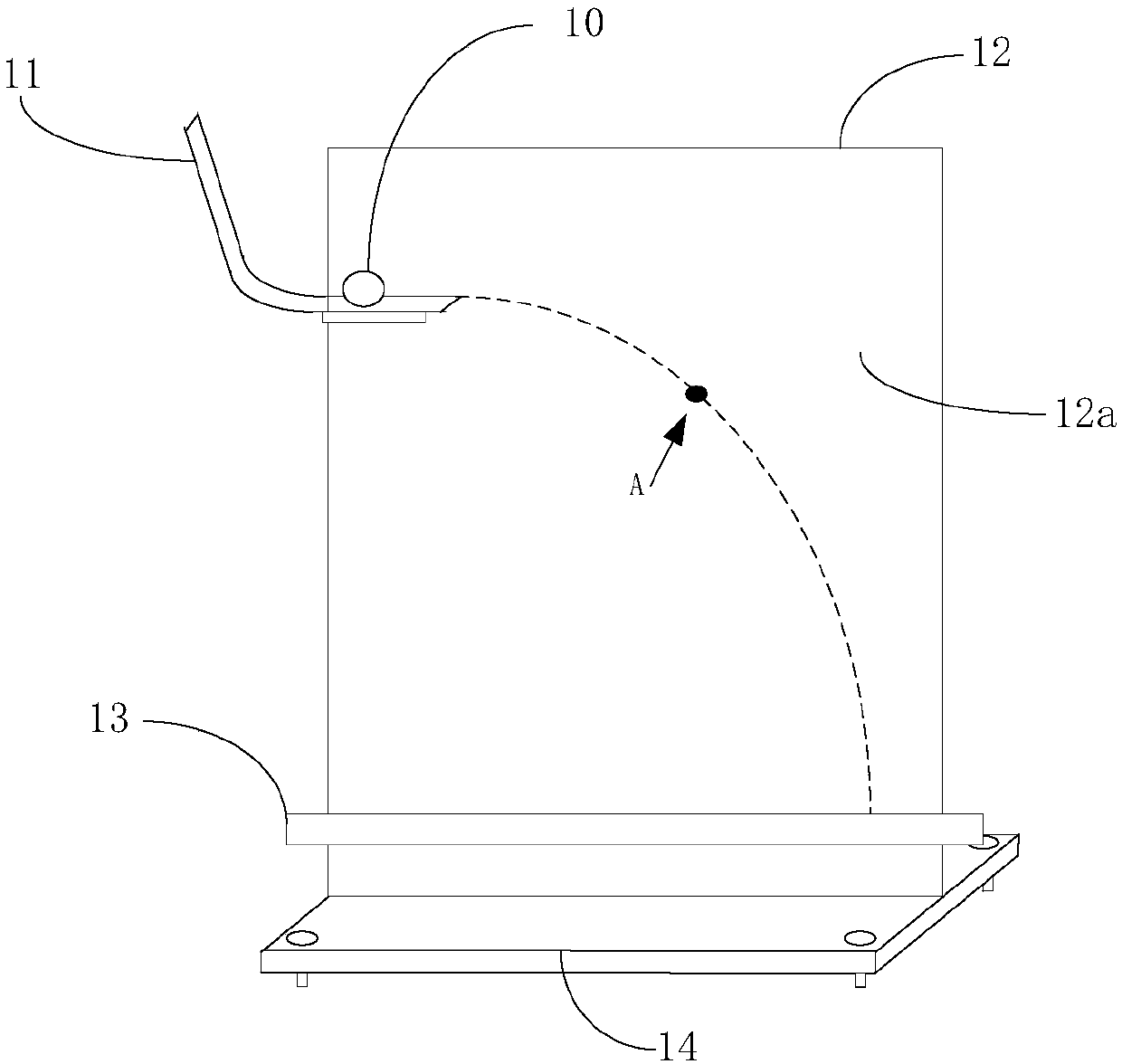

[0032] See figure 1 A schematic diagram of the structure of a parabolic motion experimental instrument shown and figure 2 A schematic diagram of the structure of the sensing circuit in the parabolic motion experiment device shown. The parabolic motion tester includes: a magnetic sphere 10, a parabolic device 11, a display board 12, a ball receiving groove 13 and a base 14. The display board 12 includes a display screen 12a, a sensor circuit (such as figure 2 (Shown) and a controller (not shown in the figure); usually, the controller can be a data processing chip such as a single-chip microcomputer, DSP, etc., integrated on the back of the base or the display board.

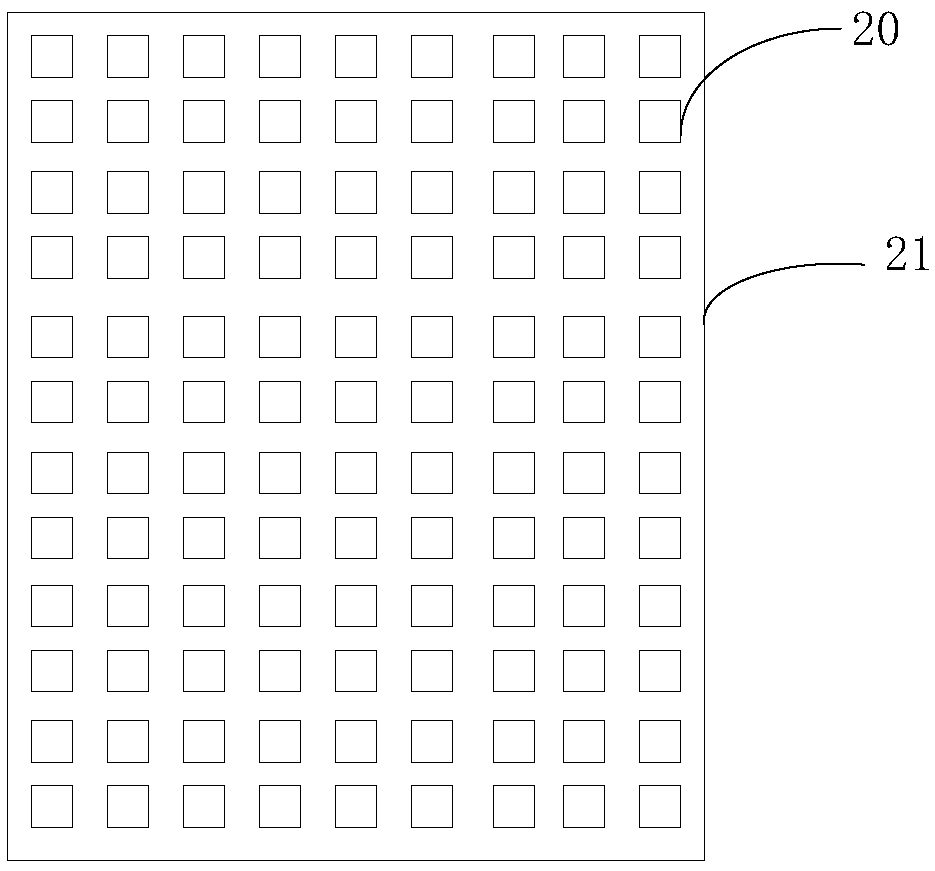

[0033] The above-mentioned display screen 12a and the sensing circuit are respectively connected to the controller; the display screen 12a and the sensing circuit are arranged overlappingly; the sensing circuit is arranged at the bottom of the display screen; that is, figure 1 In the parabolic motion tester shown, th...

Embodiment 2

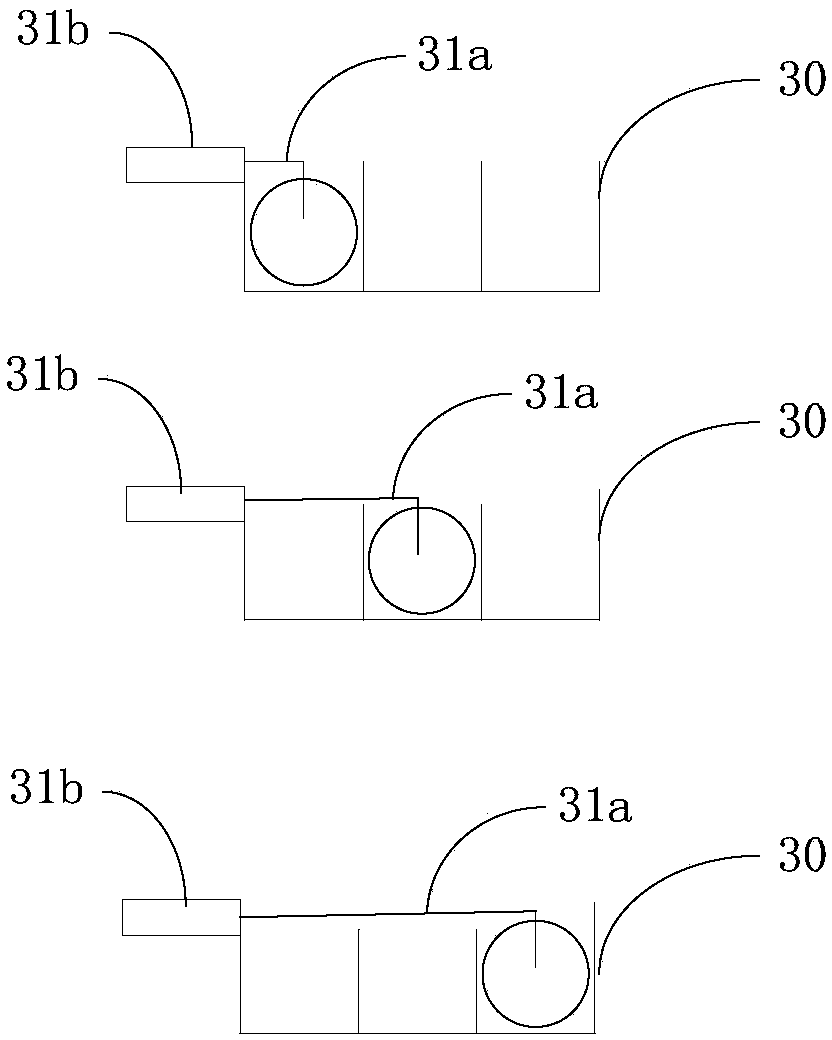

[0043] Corresponding to the parabolic motion tester provided in the first embodiment above, see image 3 In the parabolic motion tester shown, a schematic diagram of the structure of a parabolic device and Figure 4 In the shown parabolic motion tester, a top view of a parabolic device; the parabolic device is a parabolic rail 30; the number of tracks of the parabolic rail 30 is multiple ( image 3 Take three guide rails as an example); a throwing ball switch is provided on the parabolic rail 30; the throwing ball switch is slidably connected to the parabolic rail 30; the tossing ball switch is provided with a buckle part 31a and a control button 31b; the control button 31b Control the opening and closing of the buckle part 31a.

[0044] In actual implementation, since one side of the parabolic device is fixed on the display board, the control buttons of the three parabolic switches are set on the same side of the parabolic track; image 3 As shown, by arranging buckle parts of dif...

Embodiment 3

[0055] See Image 6 Shown is a schematic structural diagram of another parabolic motion tester; the parabolic motion tester is implemented on the basis of the parabolic motion tester provided in the first embodiment; specifically, the display board of the parabolic motion tester also includes a packaging frame 60; The above-mentioned display screen and the sensing circuit are arranged in the package frame 60; the base and the package frame are connected by a rotating part; the rotating part includes a bearing ( Image 6 Not shown in), the rotation angle disc 61 and the fixed part 62;

[0056] The above-mentioned bearing is arranged between the bottom side of the package frame and the base; the above-mentioned rotation angle disk 61 is arranged between the side wall of the package frame 60 and the base; the side wall of the package frame is provided with a fixing member 62; the rotation angle disk 61 is arranged There are a plurality of fixing slots 61a; the fixing component 62 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com