A flexible liquid crystal display into liquid crystal and sealing production process

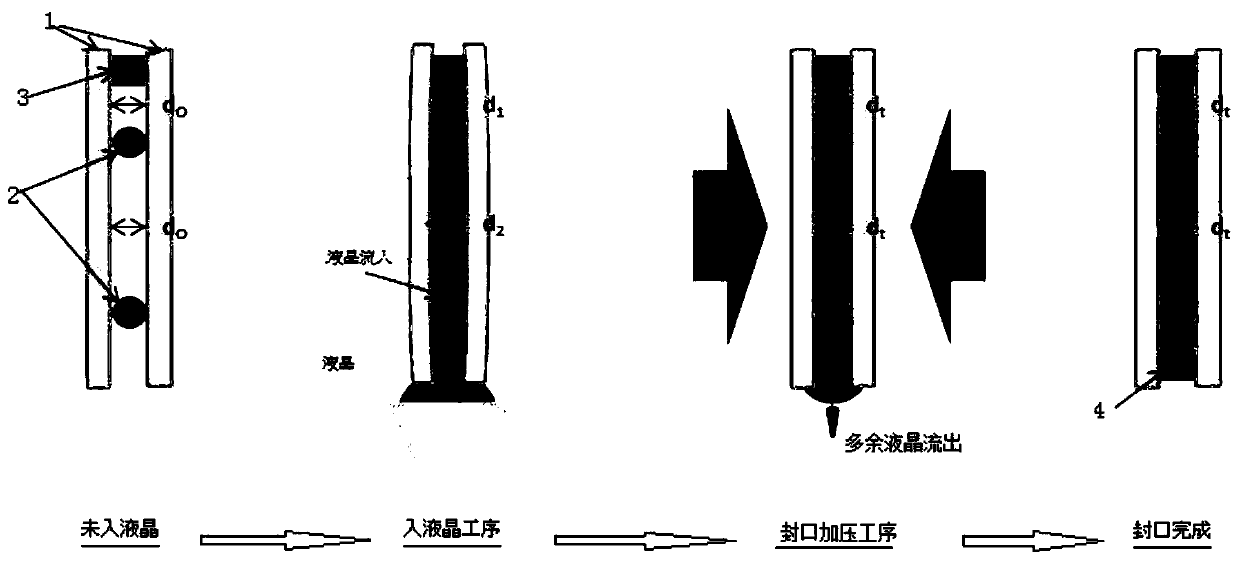

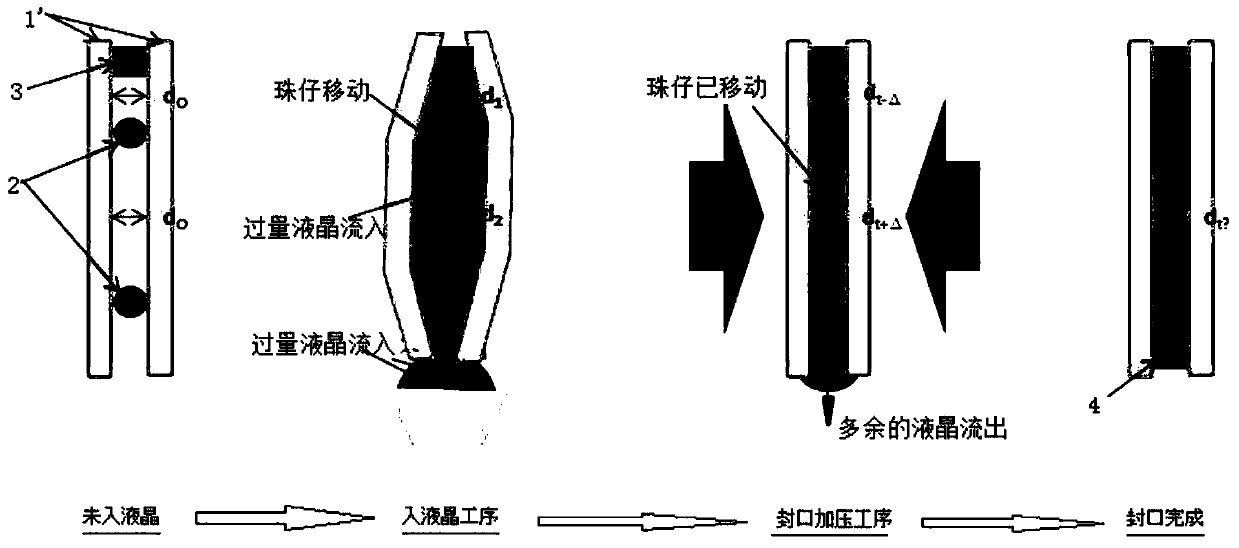

A flexible liquid crystal and production process technology, applied in the field of liquid crystal display production process, can solve problems such as liquid crystal alignment, bead 2 movement, and regional uneven box thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A production process for liquid crystal insertion and sealing of a flexible liquid crystal display, specifically including the following processes:

[0041] S1. Place the rigid pad on the surface of the flexible substrate of the liquid crystal cell;

[0042] S2. Apply pressure to the hard mat so that the hard mat fits the surface of the flexible substrate and forms an integration with the liquid crystal cell, and then keep the pressure constant. The specific pressure can be adjusted according to the hardness and area of the hard mat. In this way, it can be adjusted according to Adjust the pressure on the hard mat to control the thickness of the liquid crystal cell according to the actual production situation;

[0043] S3. Continue to keep the pressure constant and pour liquid crystal into the empty liquid crystal cell. That is to say, during the filling process of the empty liquid crystal cell, the hard pad is always attached to the surface of the flexible substrate. ...

Embodiment 2

[0051] A production process for liquid crystal insertion and sealing of a flexible liquid crystal display, specifically including the following processes:

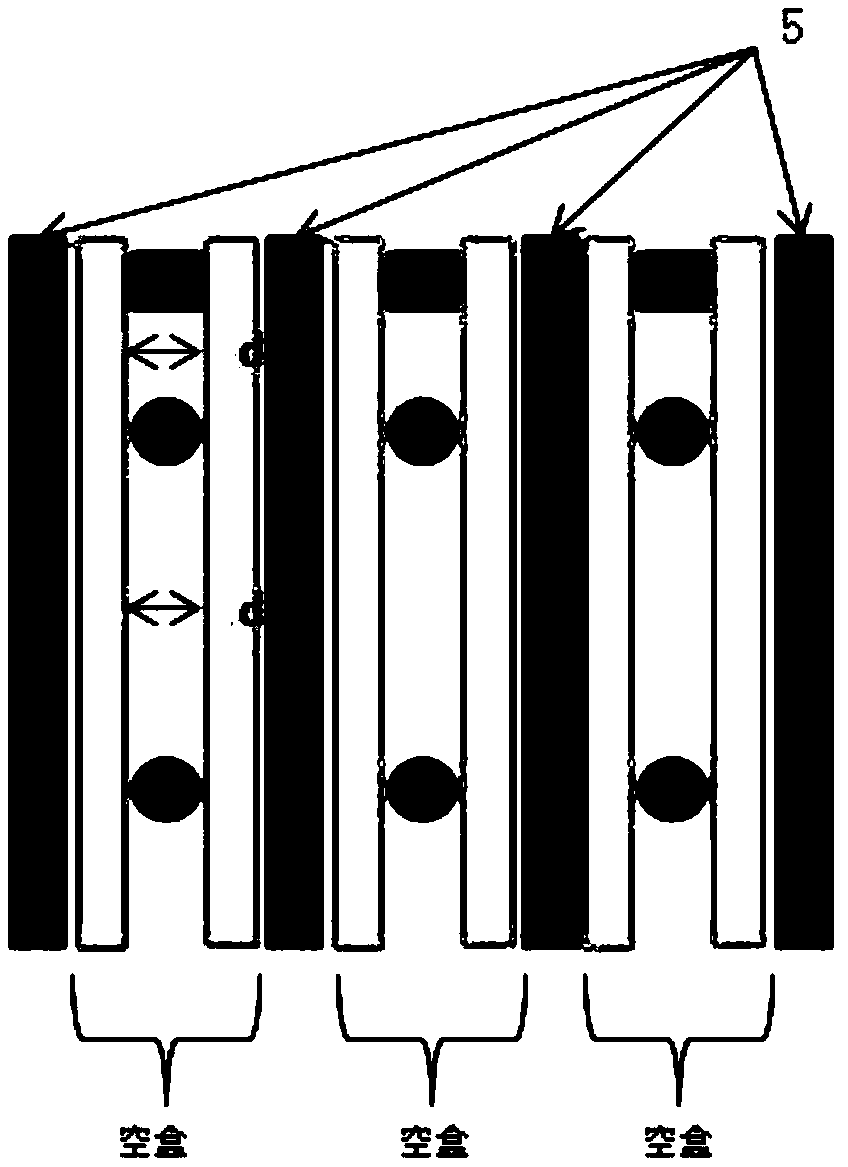

[0052] Step 1: Arrange the empty liquid crystal cells in a row, separate adjacent empty liquid crystal cells with rigid mats 5, and place rigid mats 5 on the outside of the first empty liquid crystal cell and the last liquid crystal empty cell, specifically as follows image 3 As shown, so, by arranging at intervals in rows, the traditional method of fixing the liquid crystal empty boxes on the bar frame can be changed, which can greatly improve the production efficiency. At the same time, due to the existence of the rigid mat 5, each empty box can be Sufficient space just fills and absorbs liquid crystal, and rigid cushion 5 is not easily deformed, and the thickness of liquid crystal box box can be better controlled.

[0053] Step 2: Use clamps to clamp the rigid mats 5 at both ends of the rows of liquid crystal cells in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com