Tensioning machine capable of withdrawing tapes automatically

A tensioning machine and automatic technology, which is applied to the parts of the strapping machine, etc., can solve the problems of operator discomfort, sharp edges of parts, potential safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

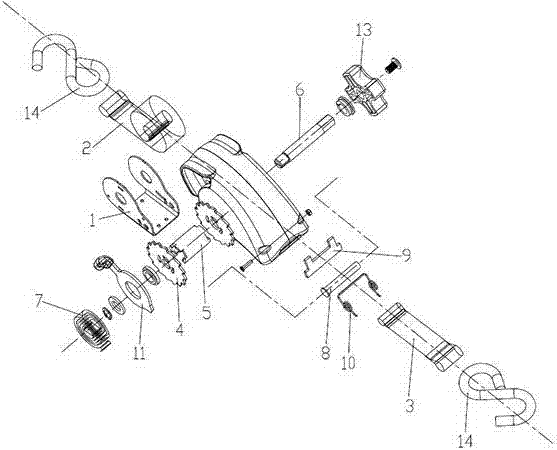

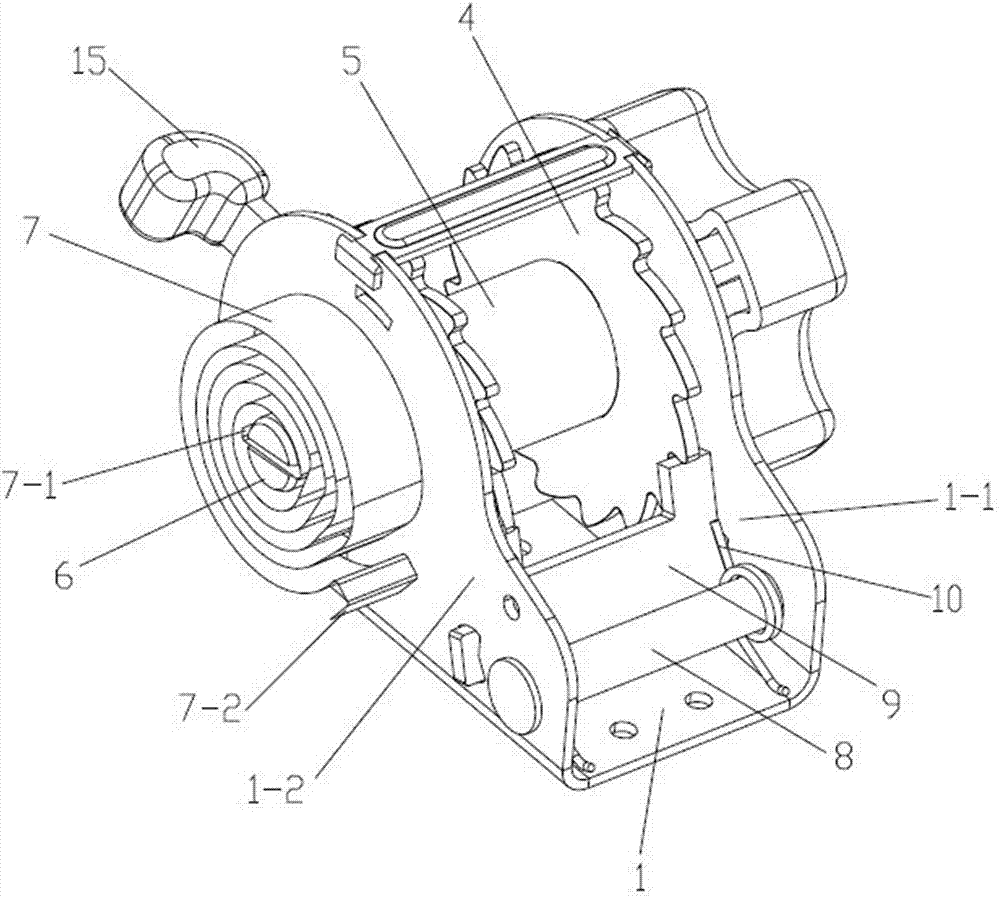

[0031] Such as Figure 1-7 As shown, an automatic take-up tensioning machine provided in this embodiment includes a base 1 with a groove 1-1 shape in cross section, a long webbing 2 and a short webbing 3, in the recess of the base 1 The slot 1-1 is provided with a ratchet wheel 4 which is sleeved on each end of both sides, and a shaft sleeve 5 with an opening 5-1 in the axial direction. The shaft sleeve 5 is hinged to the On a pair of side wall parts 1-2 of base 1, one side of base 1 is provided with coil spring 7, and one side end of rotating shaft 6 passes through its corresponding side wall part 1-2, and with coil spring The inner end 7-1 of 7 is connected, and a fixed shaft 8 arranged parallel to it is arranged on one radial side of the shaft sleeve 5, and the ends on both sides of the fixed shaft 8 extend to their corresponding side wall parts respectively. 1-2, a ratchet 9 hinged to a pair of side wall parts 1-2 of the base 1 is provided between the sleeve 5 and the fix...

Embodiment 2

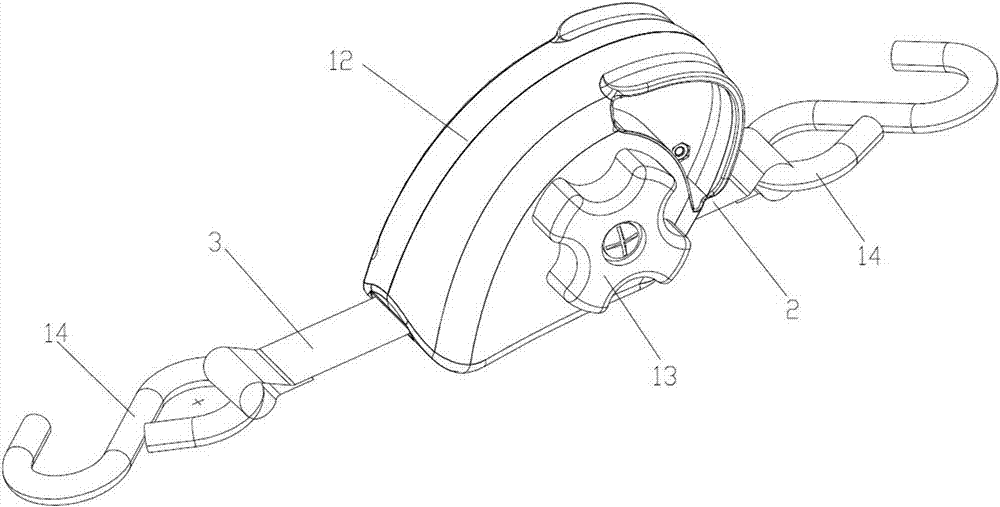

[0037] A kind of automatic take-up tensioning machine provided in this embodiment, its general structure is consistent with embodiment 1, as Figure 8 As shown, but the protective case 12 in this embodiment is mainly composed of three parts: the left half case 12-3, the right half case 12-4 and the coil spring cover 12-5, and the coil spring 7 is located in the coil spring cover 12 -5, and the coil spring cover 12-5 is fixed on the side wall part 11-2 of the base 1 on the corresponding side of the coil spring 7, after the left half shell 12-3 and the right half shell 12-4 are combined and fixed An accommodating chamber for sealing the base 1, the coil spring 7 and the coil spring cover 12-5 is formed.

[0038] For the above-mentioned automatic take-up and tensioning machine, considering that the coil spring 7 is a vulnerable part, and once damaged, it will directly affect the automatic take-up function of the automatic take-up and tensioning machine, so a coil spring is added ...

Embodiment 3

[0040] A kind of automatic take-up tensioning machine provided in this embodiment, its general structure is consistent with embodiment 2, as Figure 9 with Figure 10 shown, but one side of the lock plate 11 in this embodiment is provided with the second protruding part 11-3 for driving the ratchet 9 to compress a pair of ratchet wheels 4 when the lock plate 11 rotates, the first protrusion The part 11-1 is located below the second raised part 11-3, and a gap 11-4 is formed between the first raised part 11-1 and the second raised part 11-3, and there is no external force Under the influence of the torsion spring 10, the ratchet 9 is always snapped into the notch 11-4.

[0041] The above-mentioned lock plate 11 can promote the ratchet 9 engaged on a pair of ratchet wheels 4 to disengage from the ratchet wheel 4, and at the same time lift the handle portion 11-2 of the lock plate 11, and the second raised portion 11-3 of the lock plate 11 counterclockwise direction, the lock p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com