Cloth cutting device

A cloth and cutting technology, applied in the cutting of textile materials, textiles and papermaking, metal processing, etc., can solve the problems of reducing production efficiency, reducing cutting efficiency, increasing the burden on operators, etc., to achieve efficient cutting work and good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

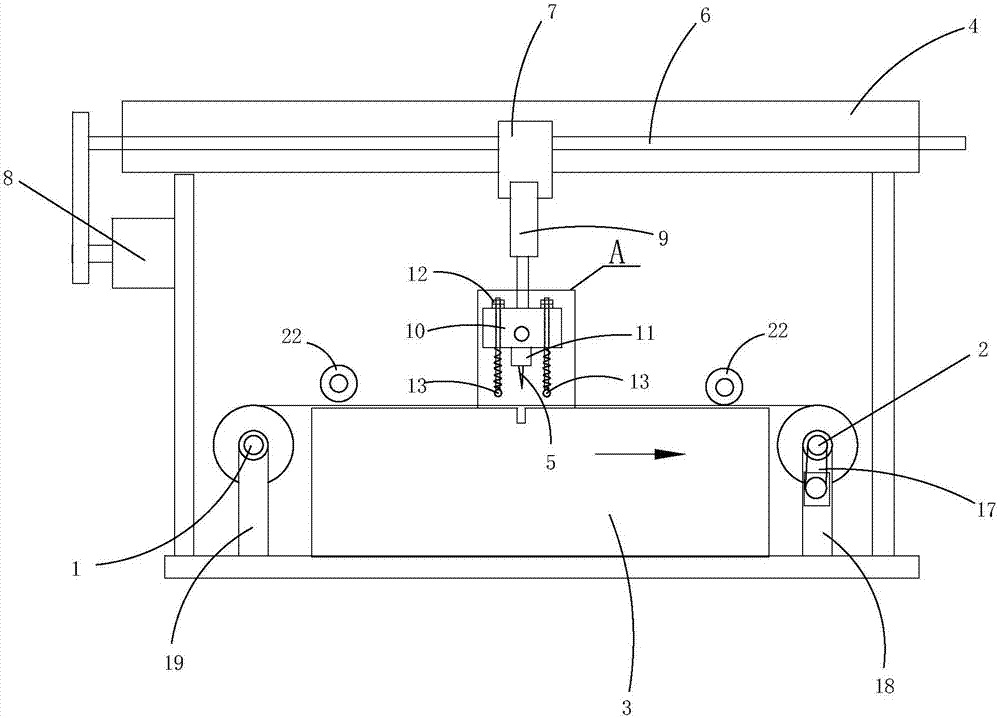

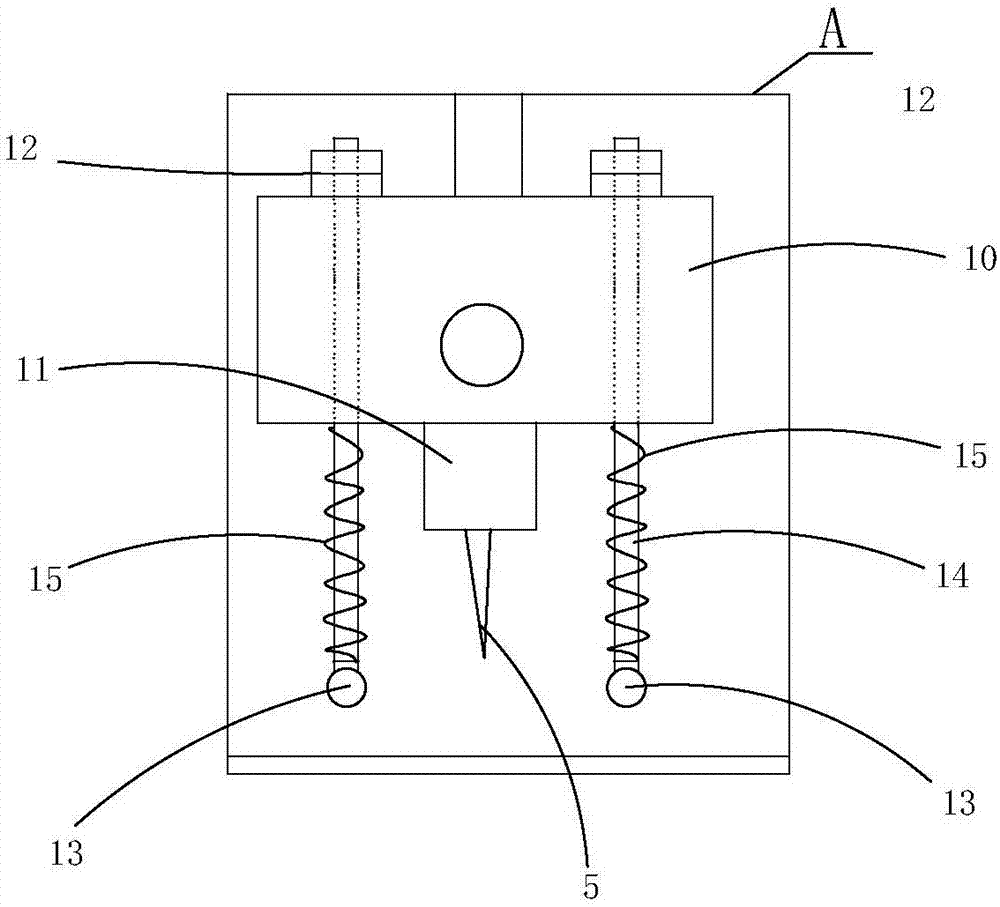

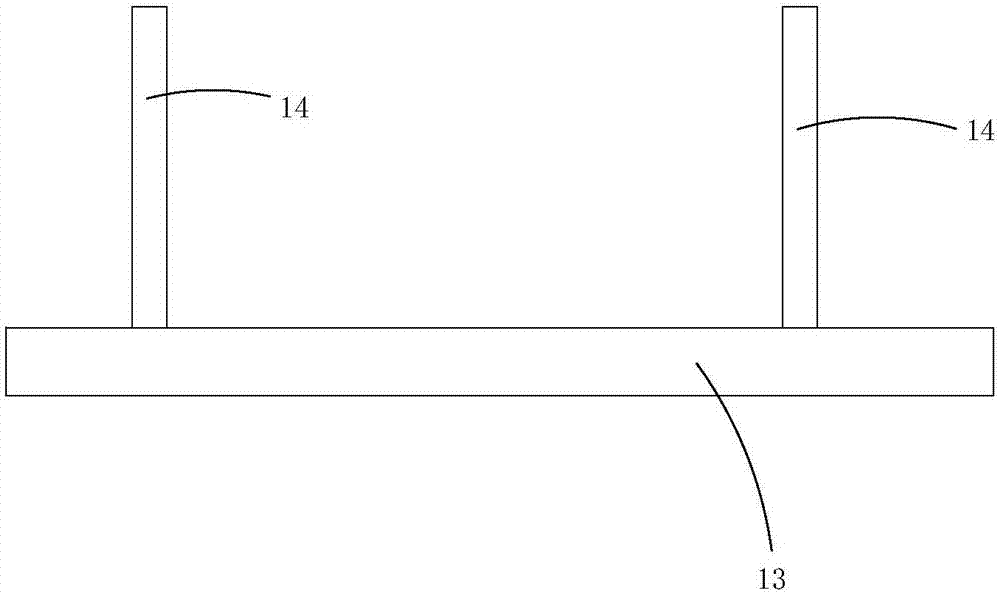

[0014] Below in conjunction with accompanying drawing, concrete structure among the present invention is described:

[0015] Such as Figure 1 to Figure 3 As shown, the cloth cutting device of this embodiment includes an unwinding positioning shaft 1 and a winding positioning shaft 2 arranged in parallel in the horizontal direction, and a positioning shaft 1 arranged between the unwinding positioning shaft 1 and the winding positioning shaft 2. The support platform 3, the gantry 4 located above the unwinding positioning shaft 1 and the rewinding positioning shaft 2, the cutter 5 for cutting the cloth, and the gantry 4 installed on the gantry 4 to drive the cutting knife 5 to move Drive mechanism; The drive mechanism includes along the cloth conveying direction (ie figure 1 The direction indicated by the middle arrow) is arranged on the screw mandrel 6 on the gantry frame 4, and the mobile frame 7 that is threadedly matched with the screw mandrel 6 and can carry out screw tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com