Air purification method of fiber dust remover

An air purification and dust collector technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as affecting exhaust gas discharge, large noise, and reduction of dust removal effects, to ensure dust removal cleanliness, reduce noise, Dust quiet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

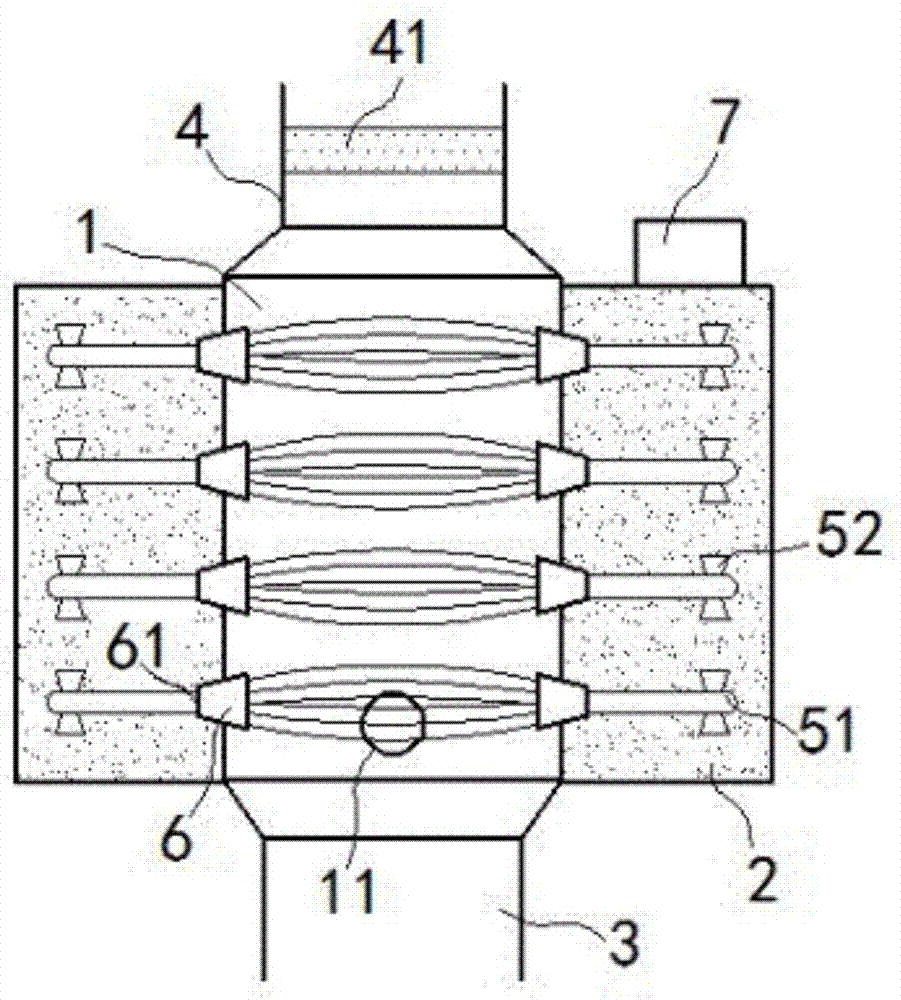

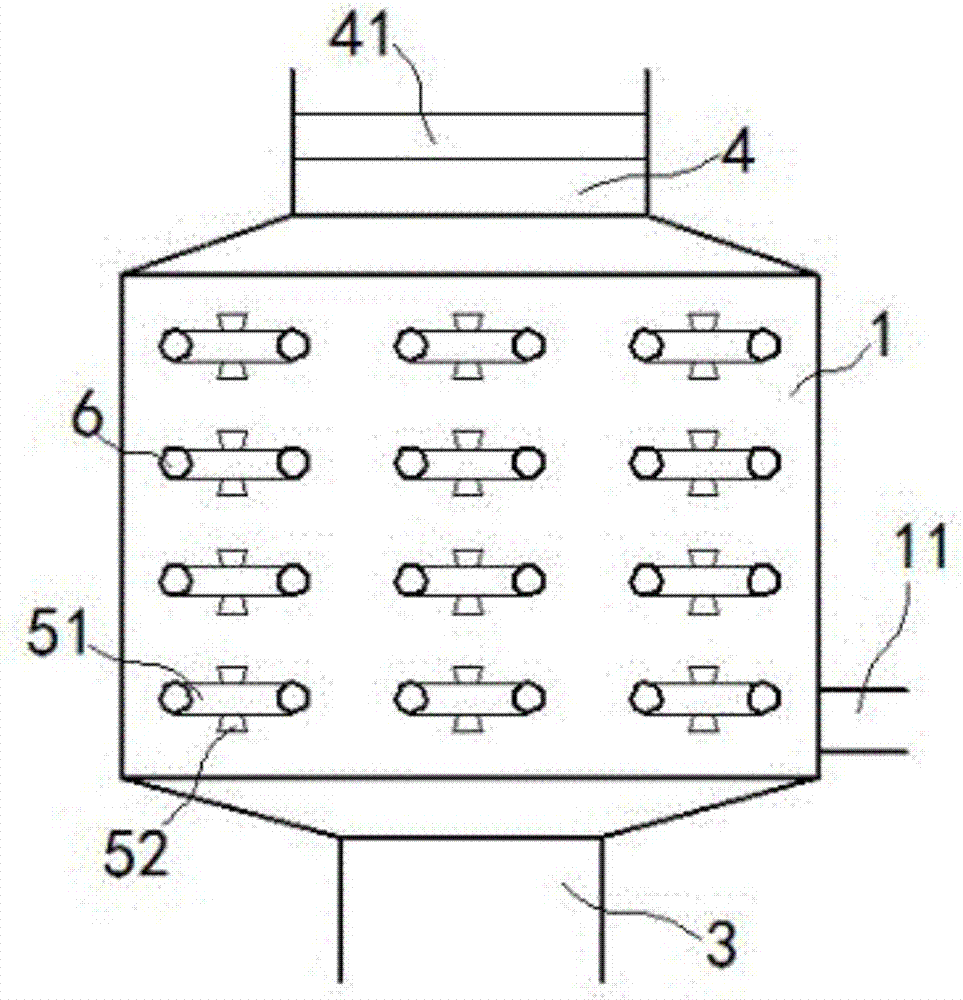

[0015] exist figure 1 , figure 2 In the shown embodiment, the fiber dust collector includes an air intake pipe 11, a dust removal chamber 1, an ash hopper 3, an exhaust pipe 4 and a cleaning chamber 2; 11 is placed at the lower end of the side wall of the dust removal chamber 1, the exhaust pipe 4 is placed at the upper end of the dust removal chamber 1, and a dryer 41 is installed in the exhaust pipe 4; the cleaning chamber 2 is installed on both sides of the dust removal chamber 1 ; Cleaning agent is filled in the cleaning chamber 2; cleaning units are arranged in an equidistant array in the dust removal chamber 1; each of the cleaning units includes a long elliptical fiber ring 51 and a driving wheel 52; The driving runner 52 is equidistantly installed in the cleaning chamber 2, and the two round ends of the fiber ring 51 pass through the sidewalls on both sides of the dust removal chamber 1 respectively, and the two round ends are sleeved on the driving runner 52. Drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com