Power system of internal combustion engine with internal cavity cam rotor

A technology for internal combustion engines and cam rotors, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of limited scalability of triangular rotor internal combustion engines, difficulty in improving rotor shaft torque, and high processing requirements for core parts. To achieve the effect of short motion transmission link, simple structure and large parameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

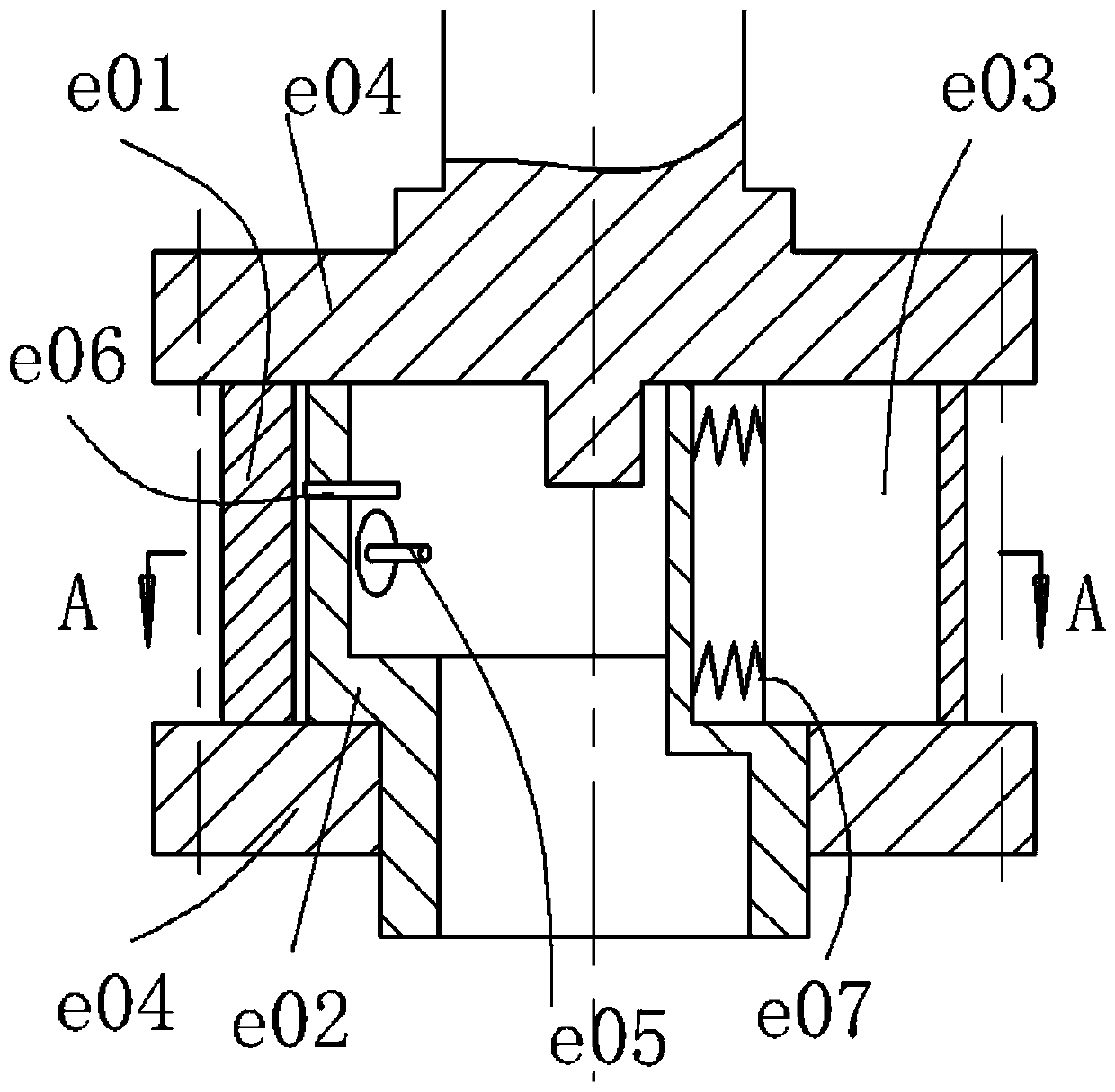

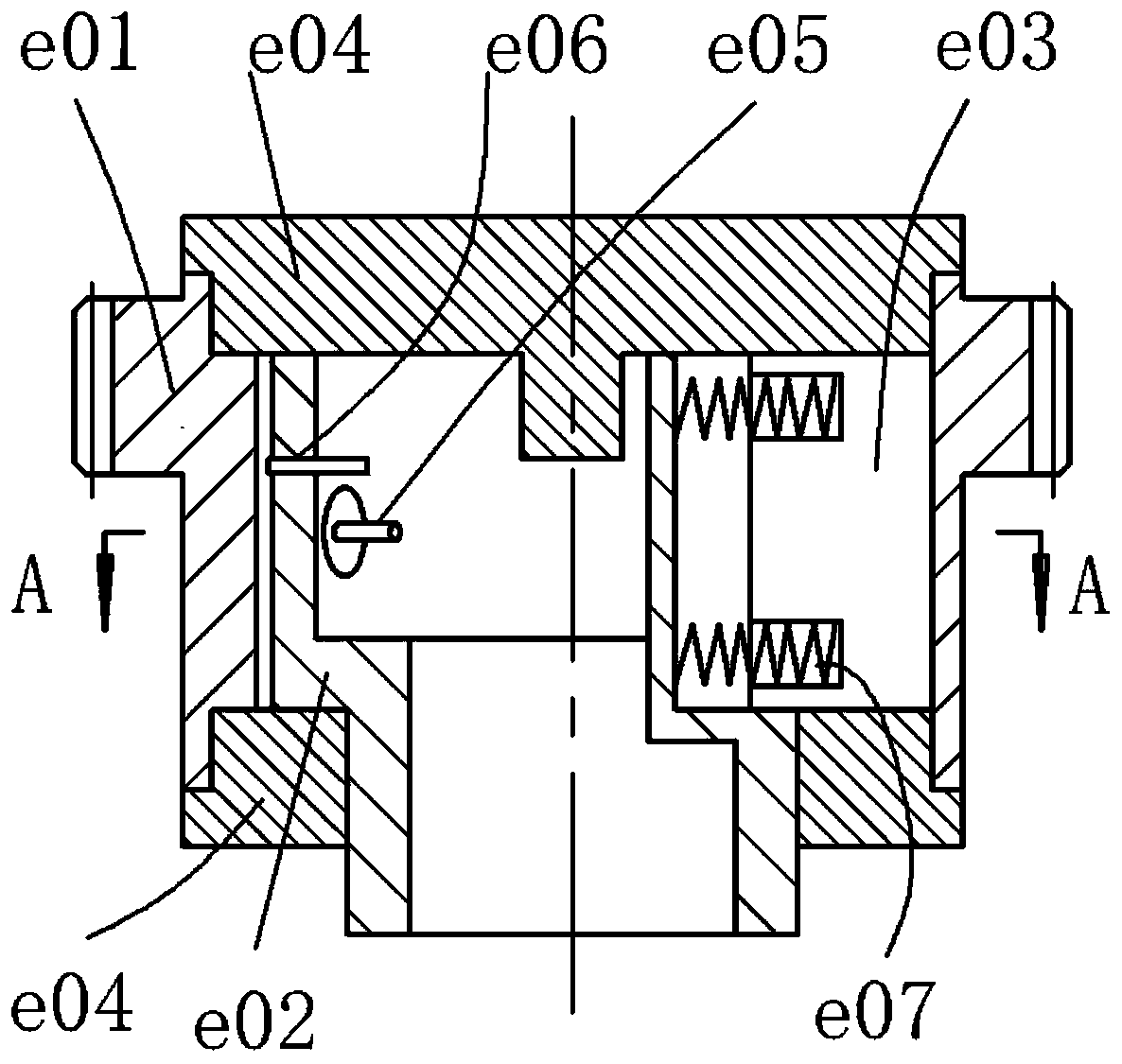

[0046] see attached Figure 4 , assuming that the central member is a fixed cylinder, the inner cavity cam rotor is a disc cam cavity with a near rest area and a far rest area, and the near and far repose angles are both slightly less than 180°. The number of sliders is 2, arranged symmetrically. The sealing relationship after assembly is the same as before, and will not be repeated. There are two intake ports and two exhaust ports, which are located inside the central member and are located on both sides of the slider. They are all represented by block valves, and the one with a small circle on the handle is the intake valve. A pair of intake and exhaust ports are a group, along the rotation direction of the inner cavity cam indicated by the arrow, the intake port in the same group is at the front, and the exhaust port is not limited. The ignition is set to two.

[0047] The two sliders divide the center member and the inner chamber of the inner chamber cam rotor into two ...

Embodiment 2

[0057] pass the following Figure 5 and 6 Demonstrate a slightly more complicated situation.

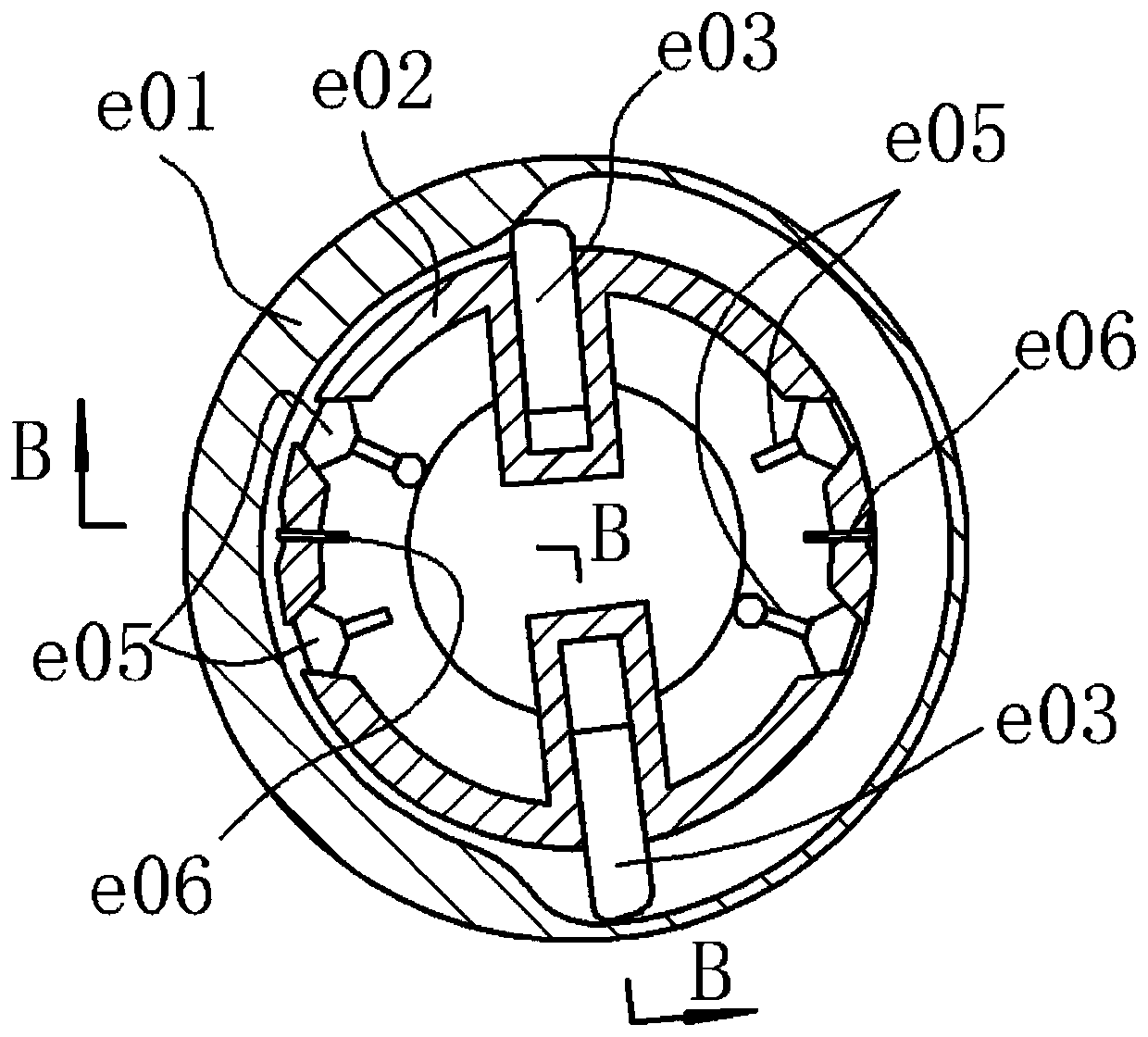

[0058] The central member is fixed, and the inner cavity cam member with the inner cavity cam profile is used as the rotor. There are three sliders on the central member, and its outer surface is evenly divided into three sections. The inner cavity cam profile has a near rest area and a far rest area. The angle of repose is as shown in the figure, that is, the near rest area of the inner cavity cam profile. The central angle corresponding to the two sliders is similar, and the space between the two sliders is the working chamber or the combustion chamber. Figure 5 and 6 The corresponding valve states and the working process in the cavity are shown in different positions of the inner cavity cam member rotor. As in the previous example, there are three working chambers, and each chamber has two possible working processes initially, so there are 8 different combined working modes...

Embodiment 3

[0069] Figure 7 Further show variability. As long as the circumferential space is large enough, the number of sliders and the number of inner cam peaks (eg, near rest areas) can be arbitrarily increased. With the addition of the slider escapement, the size of the working space for completing each work cycle can also be changed.

[0070] The parameter relationships selected below are only for convenience and clarity of description, and are not limiting. In the figure, the near-resting sections of the inner cavity cam rotor are two evenly distributed, and the arc length of the near-resting section is slightly larger than the arc length corresponding to the two adjacent sliders, so that the two sliders are in a retracted state at the same time. The number of sliders is taken as 6 and evenly distributed, indicated by numbers. Each slider is controlled by the slider escapement, where "off" means the slider has been released by the escapement, "controlled" means the slider has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com