Novel computer embroidering machine for knitting product production

An embroidery machine and knitwear technology, which is applied in the field of new computerized embroidery machines, can solve the problems of few patterns, low work efficiency, and easy dead threads, etc., and achieve the effect of many patterns and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

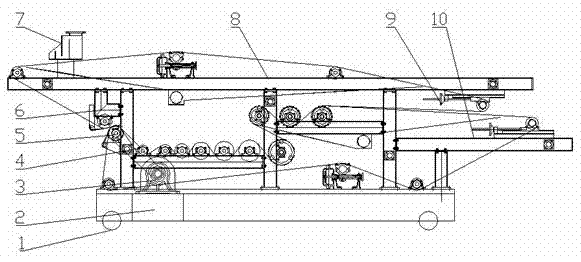

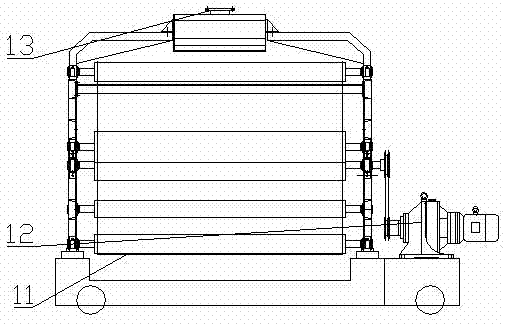

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] Such as Figure 1-Figure 2 As shown, a new type of computerized embroidery machine for knitwear production, including an embroidery machine base 1, an embroidery machine thread roller 4, a knitwear conveyor belt 8 and a small drive motor 12, and an embroidery machine thread groove 2 is installed above the embroidery machine base 1 , to place embroidery thread, embroidery machine driving wheel 3 is installed above the embroidery machine thread slot 2 to drive other parts of the embroidery machine to move, and embroidery machine thread roller 4 is installed above the embroidery machine driving wheel 3 to place the embroidery machine For embroidery threads of different designs and colors, a thread roller tensioner 5 is installed above the embroidery machine thread roller 4 to prevent the thread roller inside the embroidery machine from loosening. A conveyor belt height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com