A horizontal pushing type two-machine three-dimensional garbage disposal station

A garbage disposal station and three-dimensional technology, which is applied in the field of horizontal push-type two-machine three-dimensional garbage disposal station, can solve the problems of pollution, cross-flow of sewage polluting the environment, and high cost of modification, and achieves a simple and fast process, saves interchange time, and saves The effect of land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

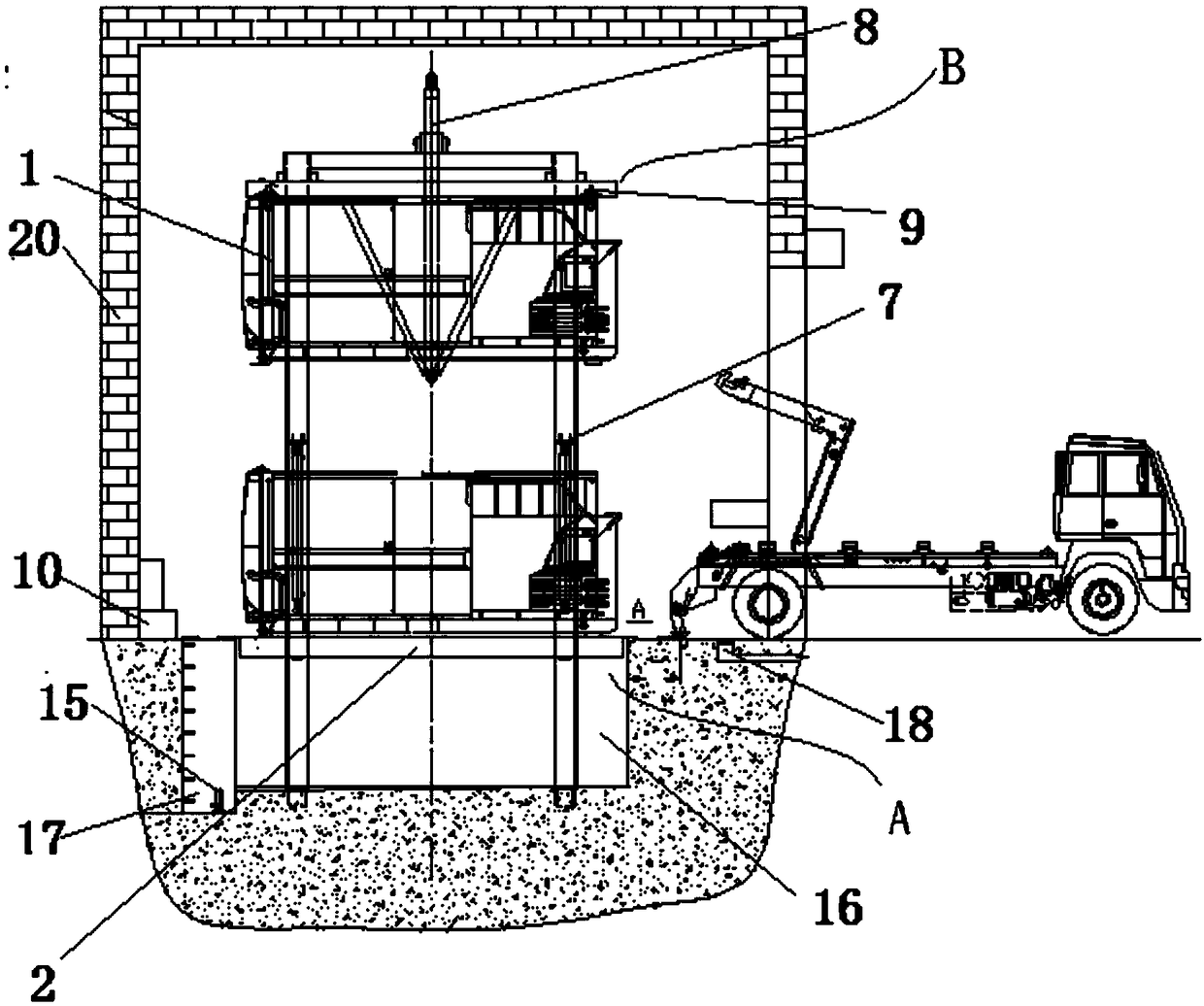

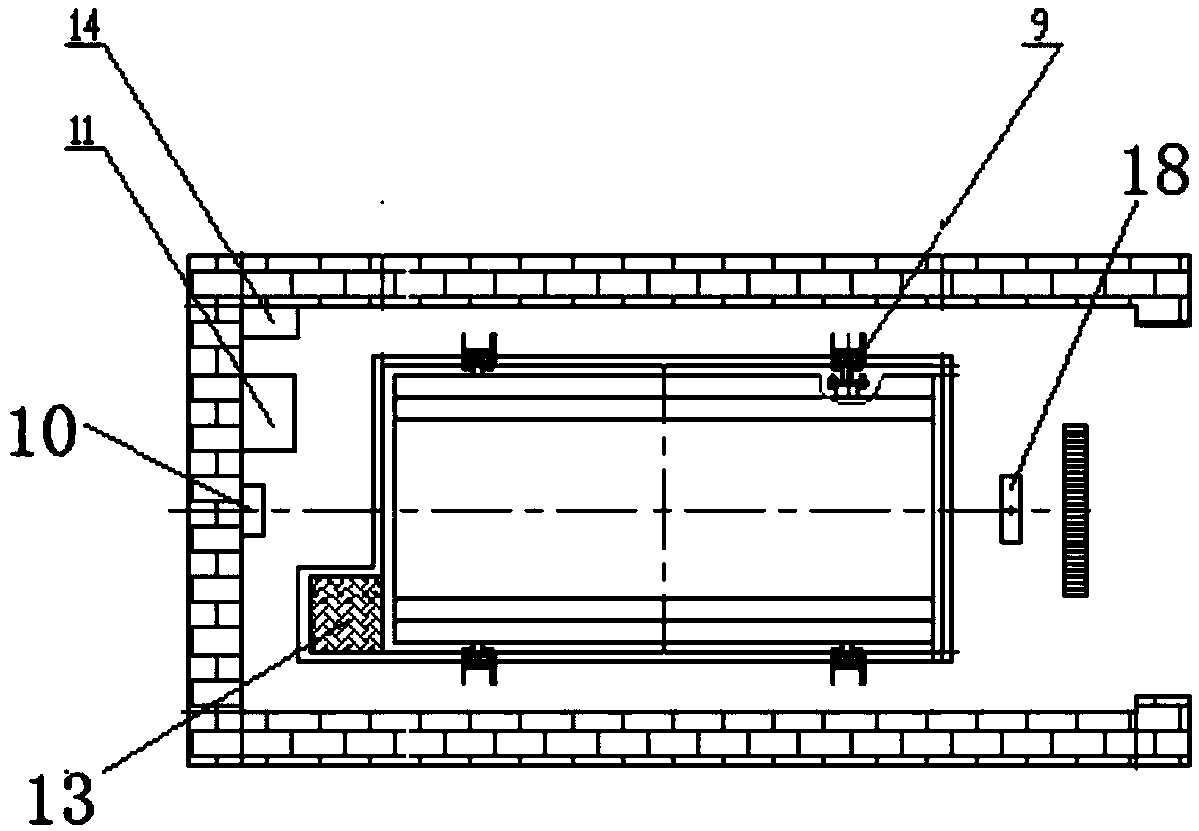

[0039] The dustbin is preferably a compressed dustbin. In order to facilitate the discharge of sewage in the dustbin, a first groove 2 is arranged along the width direction of the compressed dustbin at the bottom end of the dustbin, and the first groove 2 communicates with the outlet pipe 5. The first groove 2 is communicated with the second groove 12 arranged along the length direction of the garbage bin. The pit body 16 is provided with a water inlet 21 matched with the water outlet pipe 5 .

Embodiment 3

[0041] Such as Figure 8 As shown, in order to save the cost of the vehicle, all kinds of vehicles can be used for the transfer of garbage bins. In the garbage disposal station, a push-pull device C for pushing and pulling the garbage bin 1 is fixed. The push-pull device C is a push-pull oil cylinder. A groove 23 is provided, and the dustbin 1 is hinged with a hook 24 matched with the groove 23 . In this way, when the trash can is changed every time, the second lifting mechanism B lifts the full trash can, and then the first lifting mechanism A jacks up to be flush with the pull plate of the vehicle, and the push-pull device C pulls the empty box down the first lifting mechanism A, The first lifting mechanism A descends so that the top of the empty bin is flush with the pull plate of the vehicle; the second lifting mechanism B puts the full trash bin on the top of the empty trash bin, and the push-pull device C pushes the full trash bin to the pull plate of the vehicle superi...

Embodiment 4

[0043] Such as Figure 9 As shown, in order to save space, the push-pull cylinder in Embodiment 3 can be replaced by a shearing type telescopic frame 25, one end of the shearing type telescopic frame 25 is hinged with a cylinder 26, and the other end is hinged with a push block 27 with a groove 23, Cylinder 26 can be changed into oil cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com