Extensible welding rod structure

A technology of welding rod and welding wire, applied in the field of sustainable welding rod structure, which can solve the problems of waste of welding rod, single function of welding rod, insufficient length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

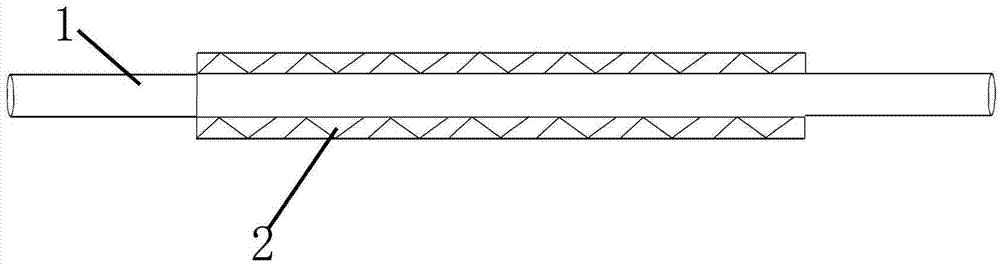

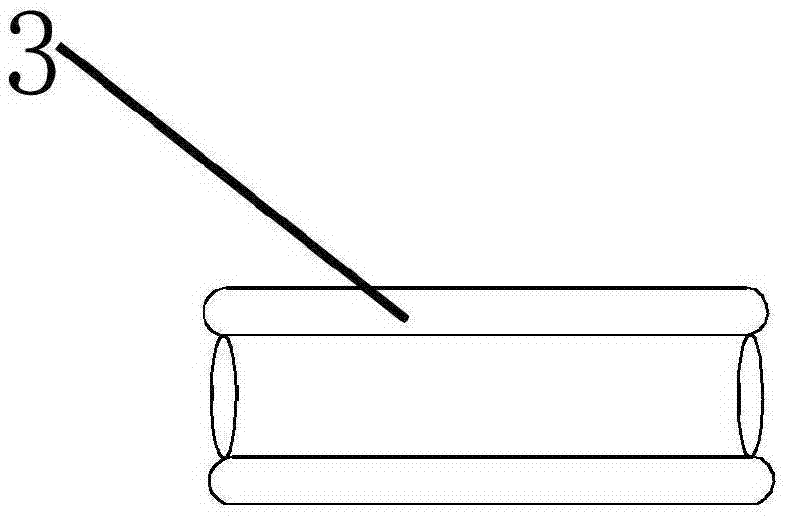

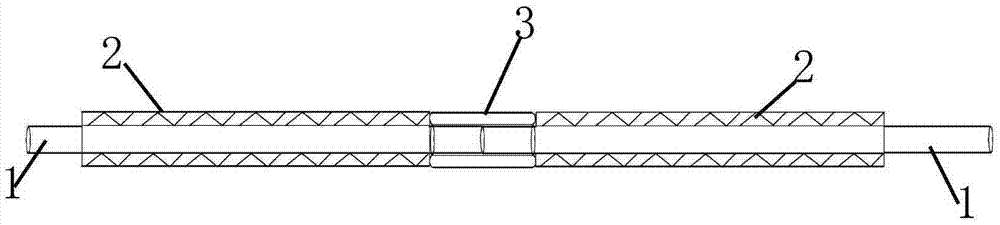

[0009] according to figure 1 — image 3 A continuous welding rod structure shown includes a main body of the welding rod and an interconnection device 3 , and is characterized in that the main body of the welding rod is composed of a welding wire 1 and a sheath 2 , and the welding wire 1 is wrapped with the sheath 2 .

[0010] The interior of the interconnection device 3 is a hollow structure.

[0011] When using the present invention, the welding wire of welding rod can be penetrated in the interconnecting device, inserts another welding rod at the other end of interconnecting device then, so just can prolong the length of welding rod; The advantages of convenience and the ability to extend the length of the welding rod, and strong market economic value are worth promoting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com