Track inspection system and track inspection method

A patrol inspection system and track technology, applied in the field of track safety, can solve problems such as long detection time, unclear changes in track parameters, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

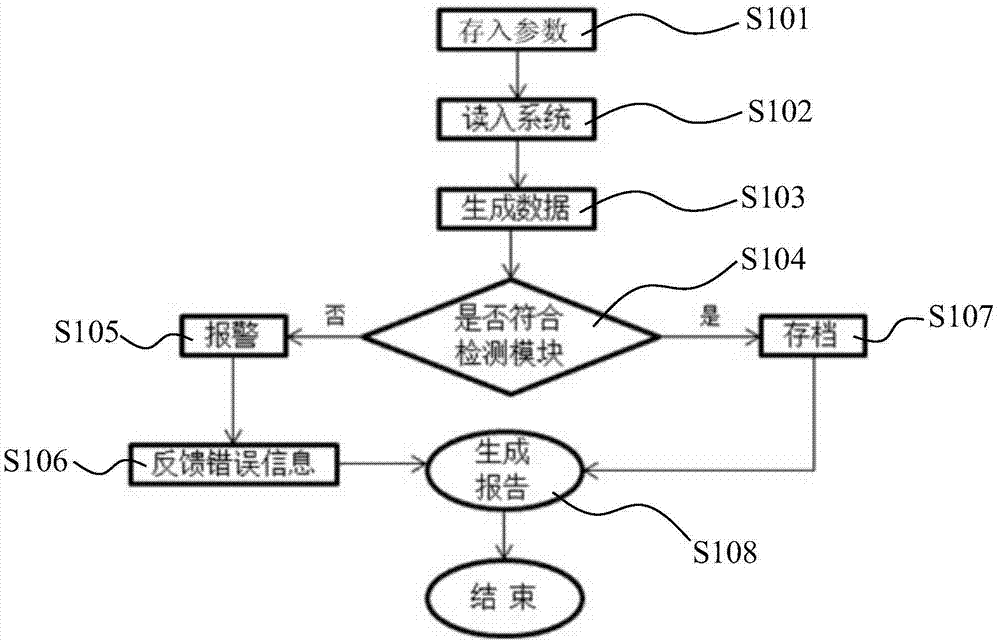

[0031] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0032] Such as figure 1 As shown, the track inspection system includes: track parameter storage module 11 , track parameter detection module 12 , signal receiving module 13 , and monitoring management module 14 .

[0033] Such as figure 1 As shown, the track parameter storage module 11 is used to store normal track parameters; the track parameter detection module 12 is arranged on the track walking robot capable of walking along the track, and is used to measure the relevant parameters of the track passing through during the track robot walking process, Track parameters include: chord height, gauge, track height difference, track horizontal bending and bolt looseness, etc. Then send parameter information to signal receiving module 13; Signal receiving module 13, receive the track relevant parameter that track parameter detection module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com