Toolbox structure for electromechanical maintenance

A technology for repairing tools and tool boxes, which is applied in the direction of manufacturing tools, tool storage devices, etc., can solve problems such as time-consuming and energy-consuming, and achieve the effects of convenient use, simple structure, and reducing the forward tilt of the center of gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

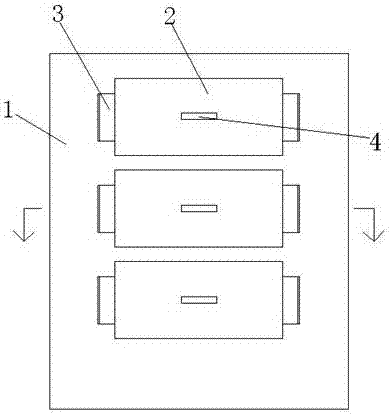

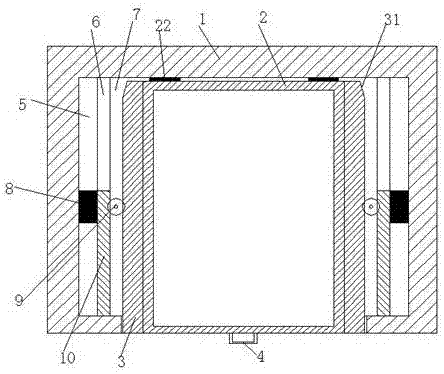

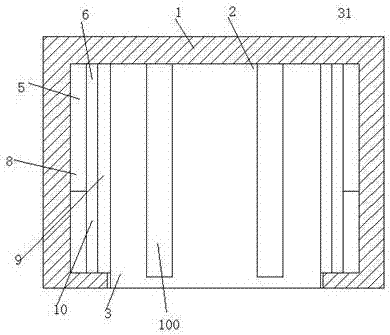

[0014] Combine below Figure 1-5 The present invention will be described in detail.

[0015] refer to Figure 1-5 , according to a tool box structure for electromechanical maintenance of the present invention, comprising a tool box body 1, a plurality of telescopic main slots arranged in the tool box body 1 and separated up and down, and installed in the telescopic main slots for swinging A plurality of storage boxes 2 for placing maintenance tools, each telescopic main groove is symmetrically provided with telescopic secondary grooves on both sides, and a slideway is arranged on the outside of the telescopic secondary groove, and the slideway includes the outer slideway 5 on the outside, the middle part The middle slideway 6 and the inside inner slideway 7, the middle part of the inner slideway 7 is equipped with an idler gear 9, the middle part of the outer slideway 5 is slidably equipped with an adjustment block 8, and the middle part of the slideway The front end of 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com