Double-rotor motor with permanent magnet-magnetic resistance axial magnetic flux composite structure

A dual-rotor motor and axial flux technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit, etc., can solve the problem of motor performance, large cogging torque, and electromagnetic problems that affect system control accuracy. Noise and other problems, to achieve the effect of improving work efficiency and power density, large output torque, and high operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

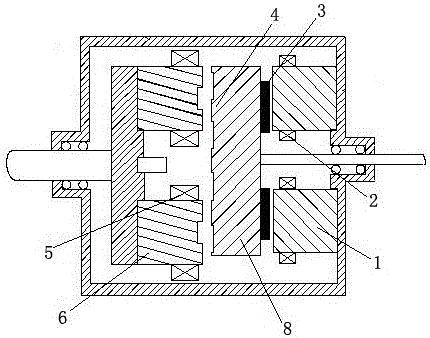

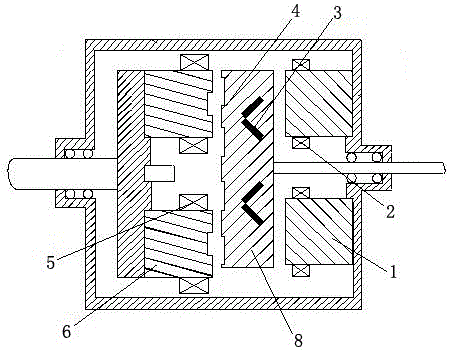

[0017] like figure 1 As shown, the present invention includes a stator 1, a first rotor 8, and a second rotor 6 arranged axially. The inner end surface of the stator 1 is a circular surface, and slots are radially divergent on the inner end surface of the stator, and three phases are placed in the slots. Distributed armature winding 2; permanent magnets 3 are installed on the side facing the stator of the first rotor 8, and the permanent magnets 3 are evenly distributed on the circular surface, and the first rotor 8 is provided with a circumferential distribution The salient pole 4; the inner end surface of the second rotor 6 diverges in the radial direction and slots, and the three-phase concentrated winding 5 is placed in the slots.

[0018] figure 1 In the illustrated embodiment, the permanent magnets 3 are arranged on the axially outer end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com