Bearing reducer center wheel housing

A technology of reducer and center wheel, which is applied in the direction of mechanical equipment, belt/chain/gear, components with teeth, etc., and can solve the problem of large radial load of the reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

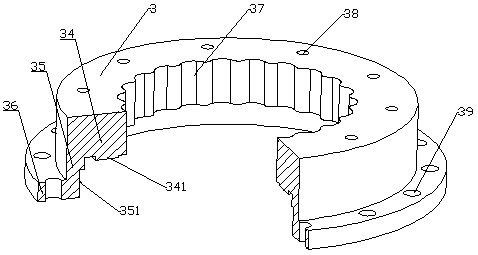

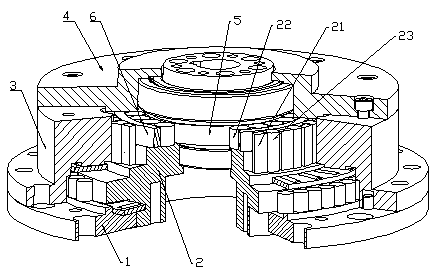

[0018] The reference signs in the drawings of the description include: bearing pressure plate 1, cage 2, retaining plate 21, inner row of balls 22, outer row of balls 23, housing 3, annular protrusion 341, groove 351, upper end plate 34, side Plate 35, lower end plate 36, slot 37, installation hole 38, assembly hole 39, cover plate 4, eccentric wheel 5, bearing ring 6.

[0019] The embodiment is basically as attached figure 1 As shown: the center wheel housing of the bearing reducer, including a cylindrical side plate 35, the upper part of the inner wall of the side plate 35 extends inward to form a ring-shaped upper end plate 34, and the lower part of the outer wall of the side plate 35 extends outward to form a ring Shaped lower end plate 36, the top of the upper end plate 34 is provided with a plurality of installation holes 38 along the circumferential direction. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com