Pressure cylinder having motion sleeve, in paticular to active cylinder

A pressure cylinder and pressure chamber technology, applied in the field of pressure cylinders, can solve problems such as uncomfortable noise and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

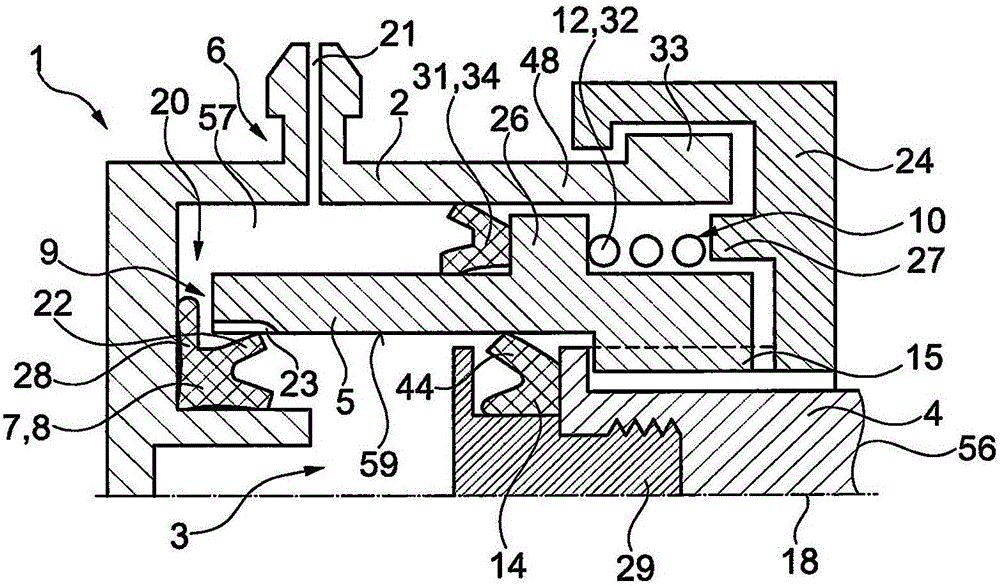

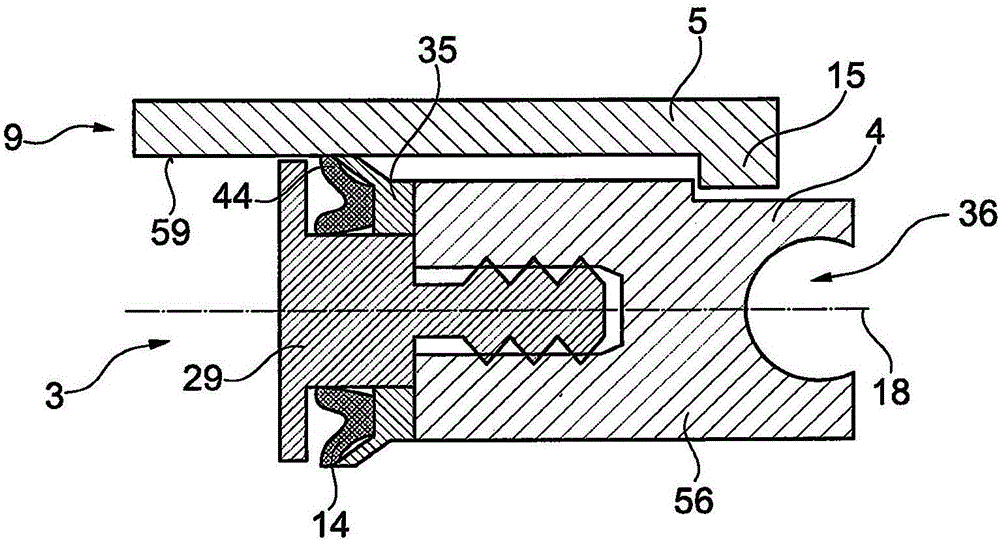

[0054] These figures are only schematic in nature and are only used for the understanding of the invention. The same elements are provided with the same reference numerals. The features of the individual embodiments can be freely combined with each other without departing from the core idea of the invention.

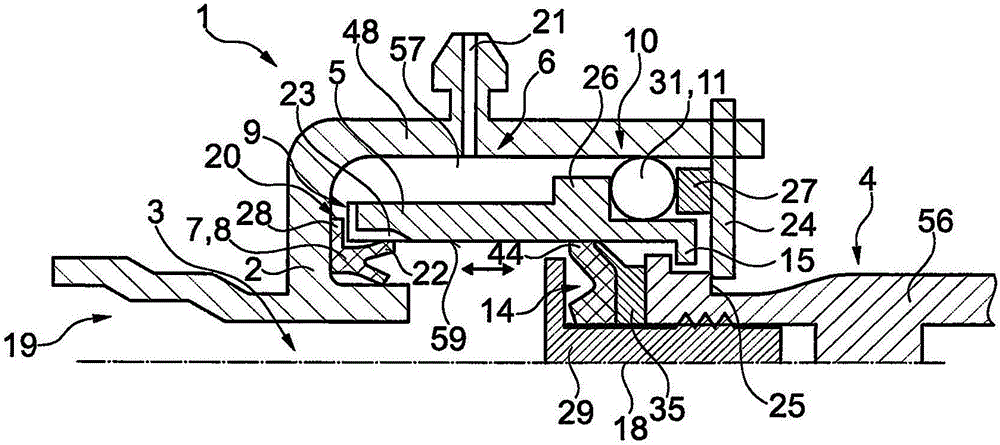

[0055] figure 1 A first embodiment of a pressure cylinder 1 according to the invention is firstly shown in . As long as it is not stated otherwise, the rest of the subsequently described exemplary embodiments correspond in construction and function to this first exemplary embodiment.

[0056] The pressure cylinder 1 is realized as a master cylinder of an actuating device for actuating a clutch of a motor vehicle. Correspondingly, the pressure cylinder 1 is used in the usual manner as a fluid pressure-generating element which can be actuated, for example, via a clutch pedal and which is fluidly connected to a slave cylinder of an actuating device in order to actuate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com