Prestressed polygon wind tower with direct fan annular box girder at tower top

A prestressed, polygonal technology, applied in the direction of towers, building types, buildings, etc., can solve the problems of complex transition sections, many materials, and indirect force transmission, so as to achieve direct force transmission, improve utilization, and save materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

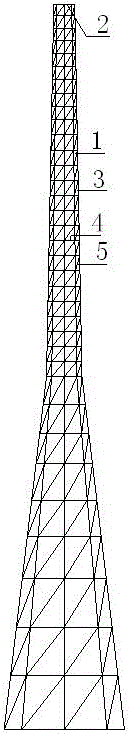

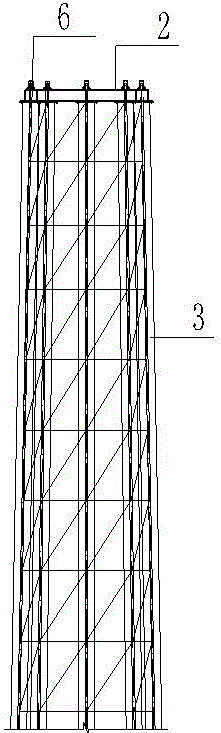

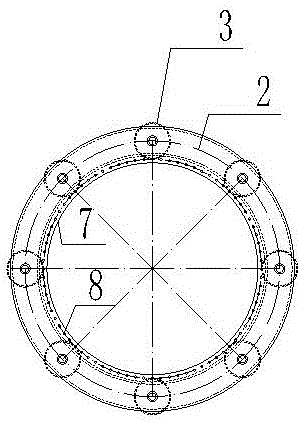

[0017] refer to Figure 1-Figure 6 , a kind of prestressed polygonal wind tower with tower top direct wind turbine annular box girder of the present embodiment, it comprises steel structure lattice type tower body 1, fan nacelle connection flange 14 and annular box girder 2, and described annular box The beam 2 is connected to the top of the steel structure lattice tower body 1. The steel structure lattice tower body 1 includes a tower column 3, a cross bar 4, and a diagonal bar 5. The inside of the tower column is provided with a prestressed steel strand 6 , the annular box girder 2 includes an annular box girder upper flange 7, an annular box girder web 12, an annular box girder lower flange 11, and a ring beam bottom flange 9, and the internal prestressed steel strand 6 of the tower column is anchored in the annular On the upper flange 7 of the box girder, the connecting flange 14 of the fan nacelle is connected with the annular box girder 2 .

[0018] The steel structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com