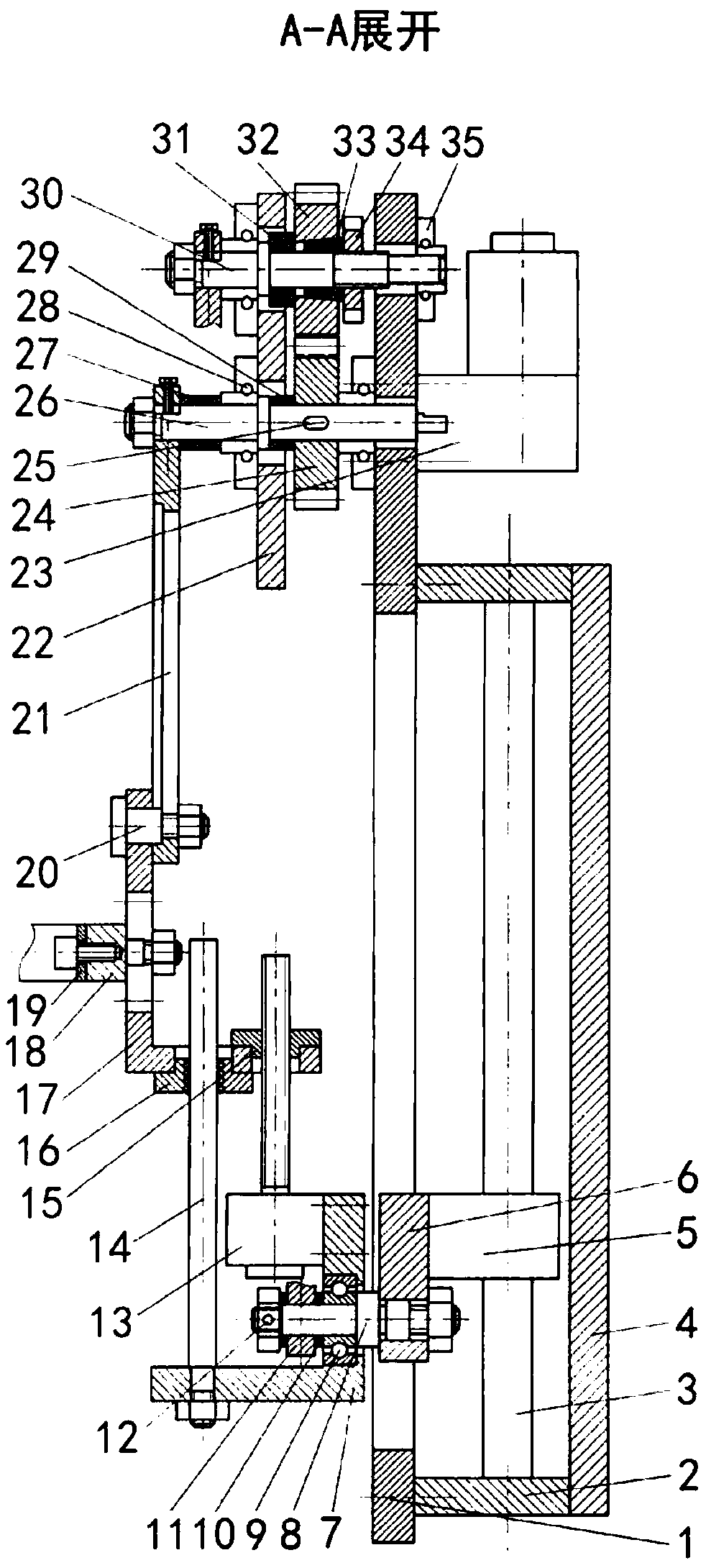

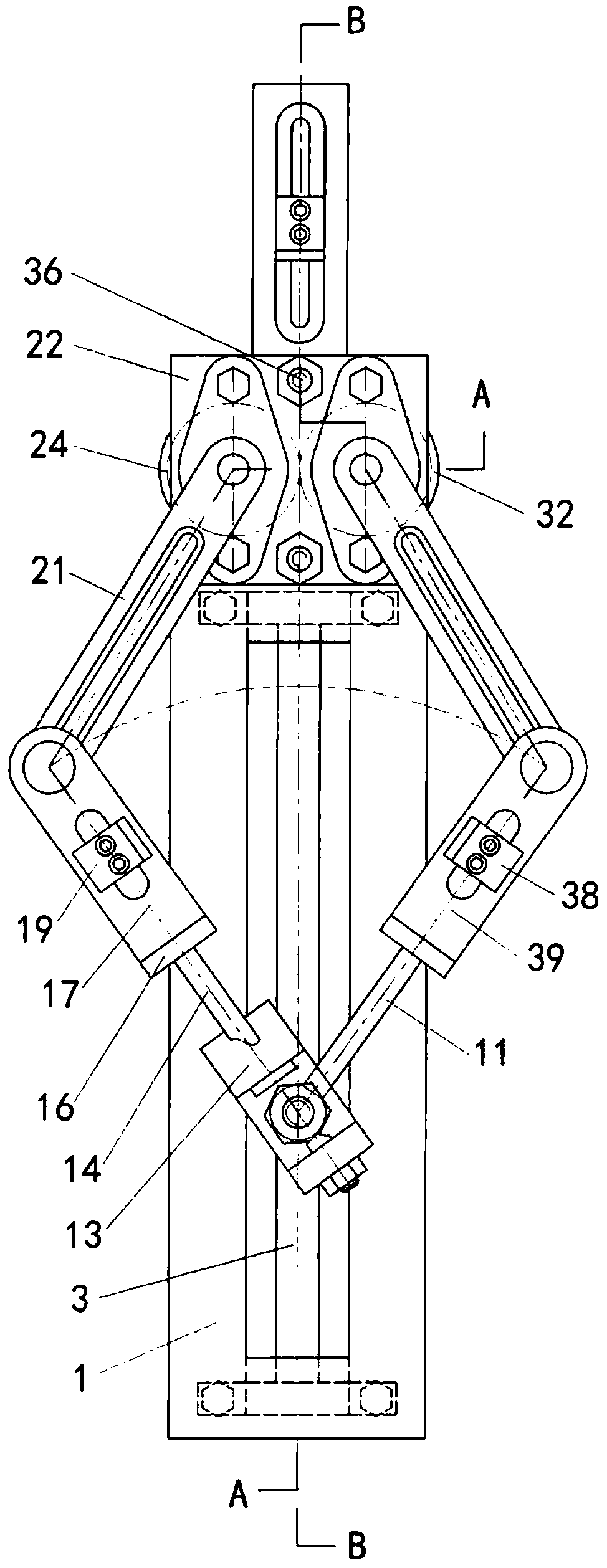

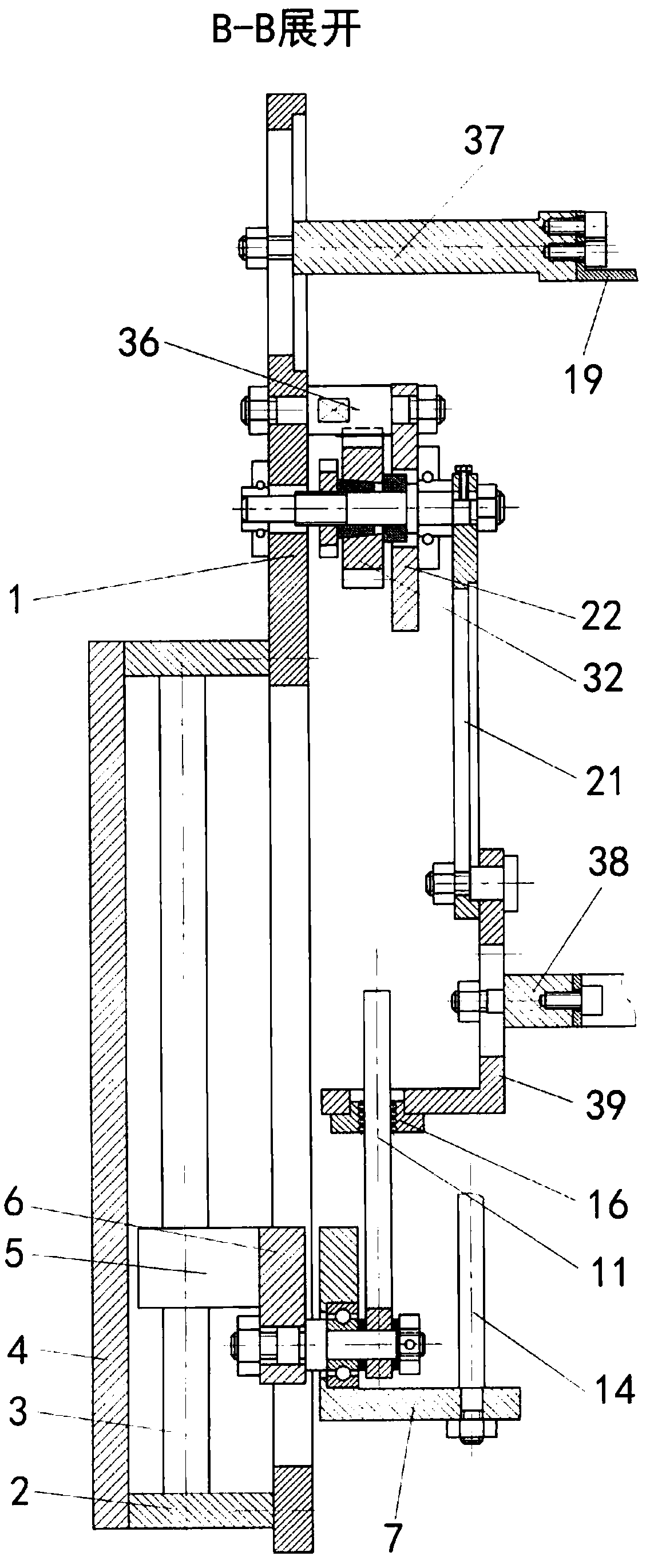

Palm-type manipulator with double-drive crank-slider parallel mechanism with finger displacement and indexing

A crank-slider, dual-drive technology, applied in manipulators, program-controlled manipulators, joints, etc., can solve problems such as high cost, and achieve the effect of good size adaptability and rapid angular displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0056] The first implementation mode is that when none of the five manual methods are used, only through the coordinated control of two stepping motors, it can be realized: Figure 25 As shown, it is the grasping effect of the palm-type manipulator of the parallel mechanism of the present invention to grasp the large rectangle with three fingers; Figure 26 As shown, it is the grasping effect of the three fingers of the parallel mechanism palm-type manipulator of the present invention to grasp the small rectangle; Figure 27 As shown, it is the grasping effect of the three fingers of the palm-type manipulator of the parallel mechanism of the present invention grabbing the small circle; as attached Figure 28 As shown, it is the grasping effect of the three fingers of the parallel mechanism palm-type manipulator of the present invention to grab the large circle; as attached Figure 29 Shown, for the present invention parallel mechanism palm type manipulator three fingers grasp...

Embodiment approach 2

[0057] Embodiment two is: manual adjustment, the short finger seat 18 and the middle finger seat 38 on the left and right side connecting rods rotate the same angle in the opposite direction, as attached Figure 31 As shown, it is the grasping effect of the two fingers of the parallel mechanism palm-type manipulator of the present invention to grab a large rectangle; Figure 32 As shown, it is the grasping effect of the palm-type manipulator with two fingers of the parallel mechanism of the present invention grasping the small rectangle.

Embodiment approach 3

[0058] The third embodiment is: manual adjustment, the eccentric distances of the two cranks are different, as attached Figure 33 As shown, it is a simplified schematic diagram of the state of unequal eccentricity of the crank of the palm-type manipulator of the parallel mechanism of the present invention, which can realize the grasping of asymmetrical objects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com