Faucet valve element assembler

A technology for assembly machines and faucets, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low automation, low assembly efficiency, and high equipment cost, and achieve the effects of improving process efficiency, compact structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

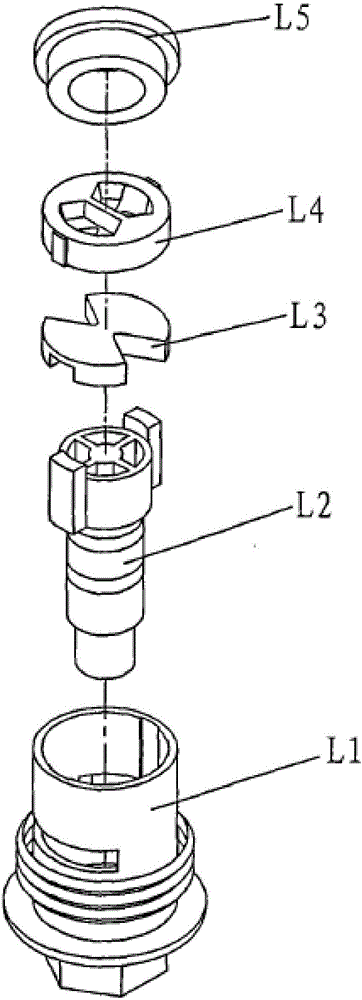

[0036] Such as figure 1 As shown, the faucet spool to be assembled in this embodiment is a ceramic spool, including a housing L1, a valve stem L2 covered with an O-ring, a movable ceramic sheet L3 that cooperates with the valve stem L2, and a movable ceramic sheet L3 that is attached to each other. The combined fixed ceramic sheet L4 and the rubber gasket L5 for sealing, of course, the casing L1 also needs to be sleeved with a sealing ring. It should be noted that there are two types of ceramic valve cores: rotary ceramic valve core and swing rod ceramic valve core. In this embodiment, the rotary ceramic valve core will be described as an example.

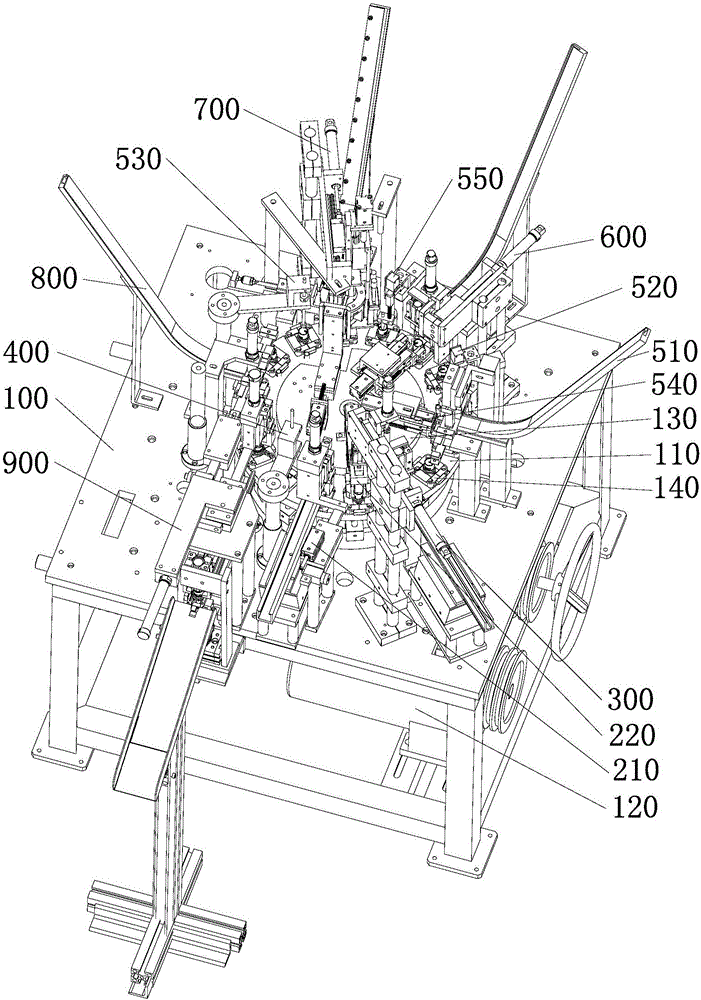

[0037] Such as figure 2 Shown is the faucet spool assembly machine provided in this embodiment, which includes a frame 100, on which is provided a horizontally arranged turntable 110, a rotary dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com