Single-shaft shredder

A shredder and single-shaft technology, applied in the direction of grain processing, etc., can solve the problems of low crushing efficiency, low blanking efficiency, and non-contact of moving knives, and achieve the effect of improving crushing efficiency and reducing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

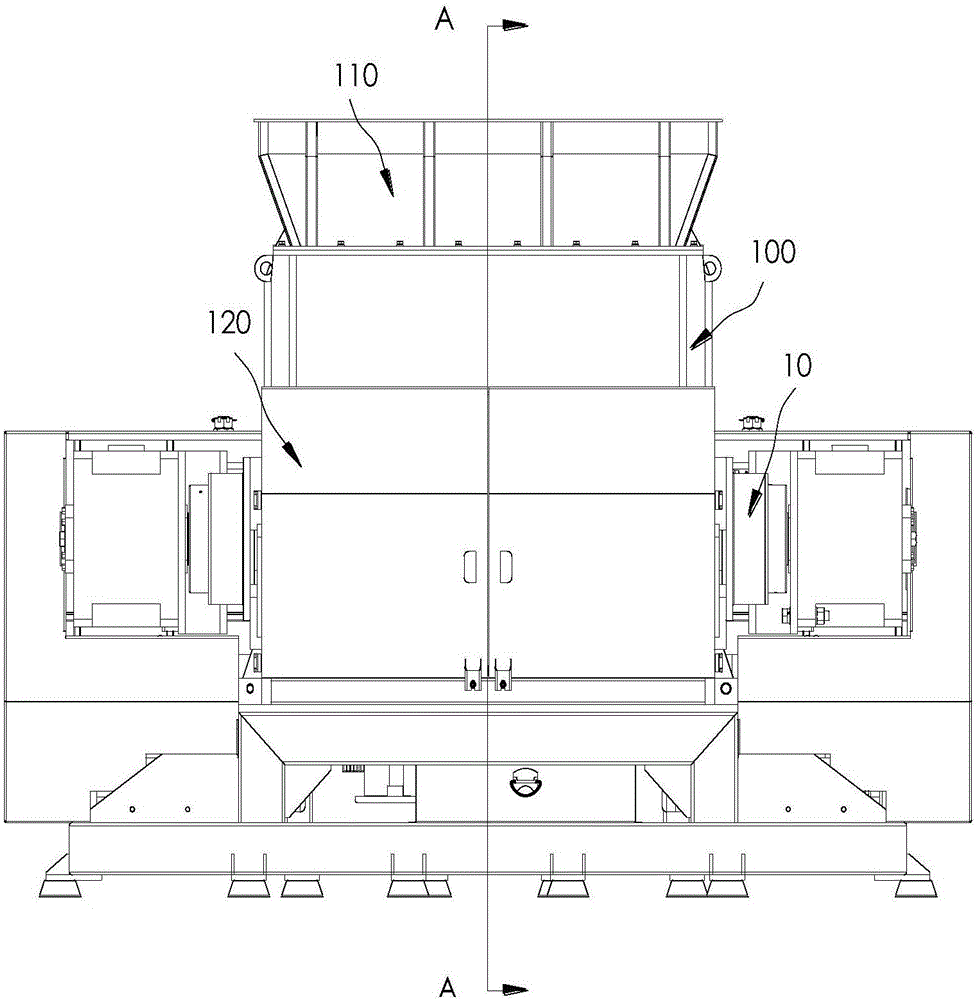

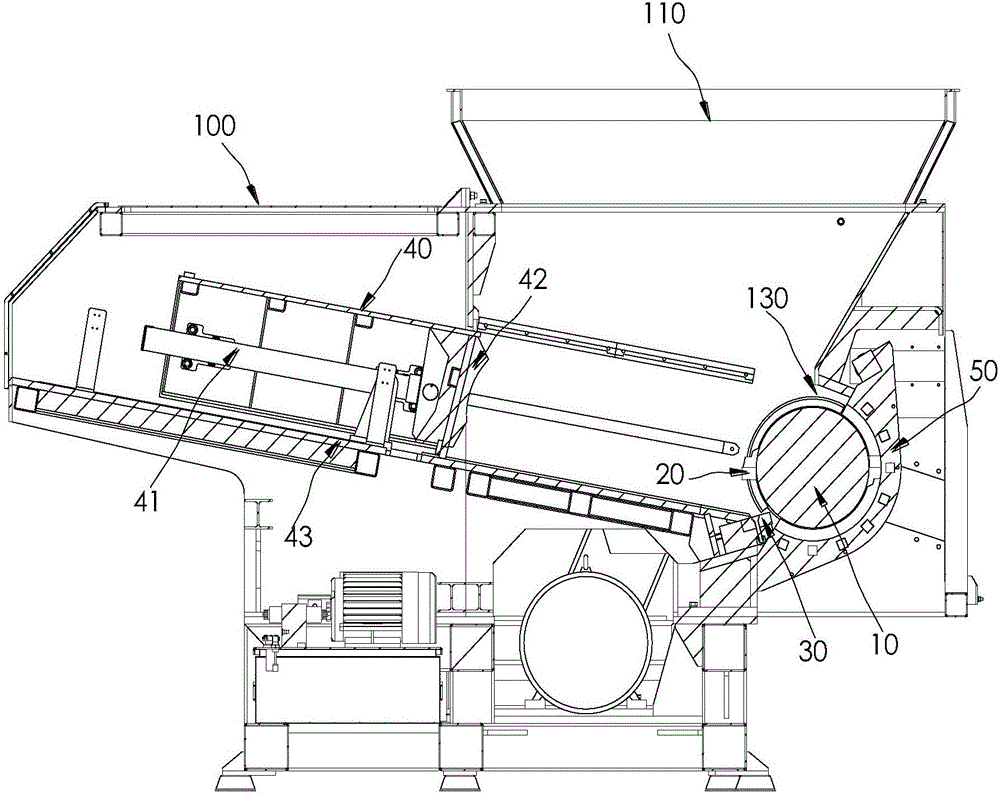

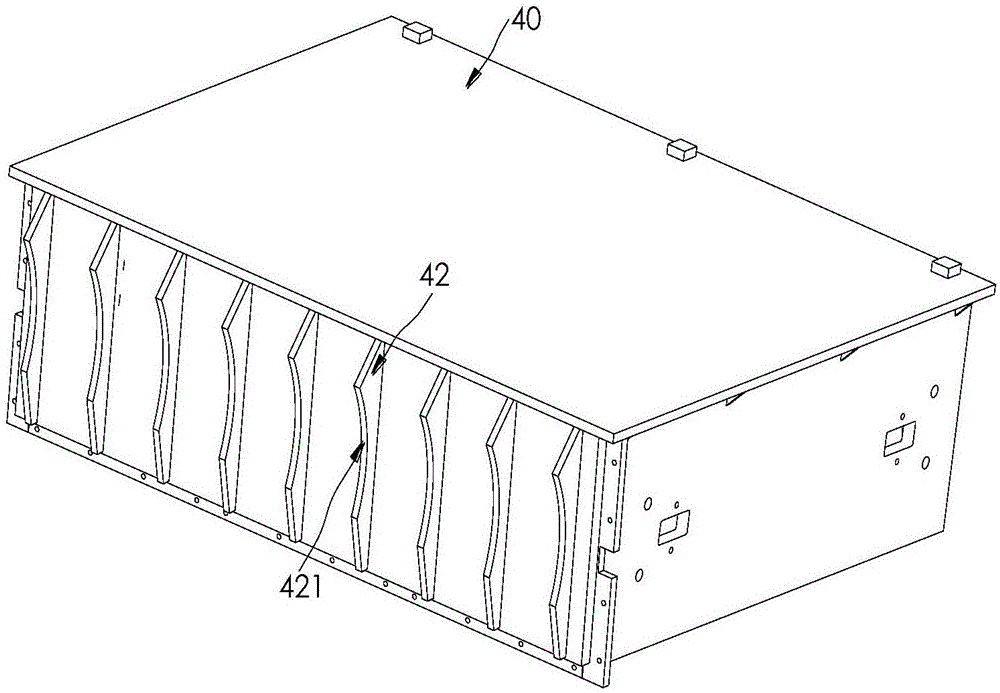

[0029] like figure 1 , figure 2 as well as image 3 The shown single-shaft shredder includes a box body 100 , a cutter assembly and a pushing mechanism, and a crushing cavity 130 is formed at one end of the box body 100 . The knife assembly specifically includes a fixed knife 30, a plurality of moving knives 20 and a knife shaft 10, so that the knife shaft 10 is pivotally connected in the crushing cavity 130, and a plurality of moving knives 20 are all installed on the outer surface of the knife shaft 10, and at the same time, the fixed knife The knife 30 is fixed on one side of the crushing chamber 130, so that the fixed knife 30 is spaced apart from the outer surface of the knife shaft 10 to form a cutting gap.

[0030] In addition, the above-mentioned pushing mechanism is installed at the end of the box body 100 away from the crushing chamber 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com