Triaxial holder, shooting robot and control method

A technology of a gimbal and shaft motor, applied in the direction of control without feedback, can solve the problems of line winding, automatic gimbal equipment cannot complete shooting, etc., to achieve strong tracking ability and improve the effect of tracking shooting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

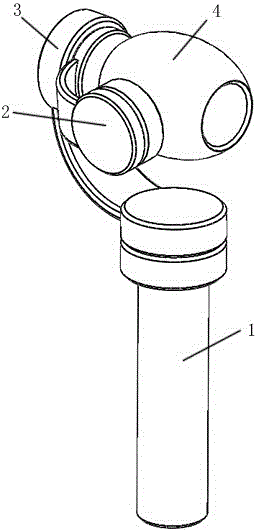

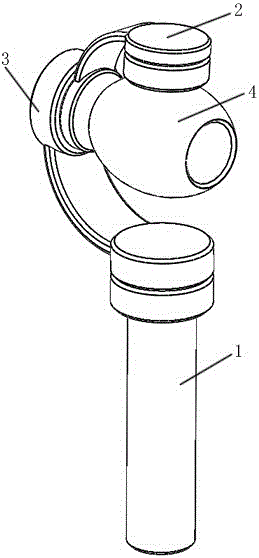

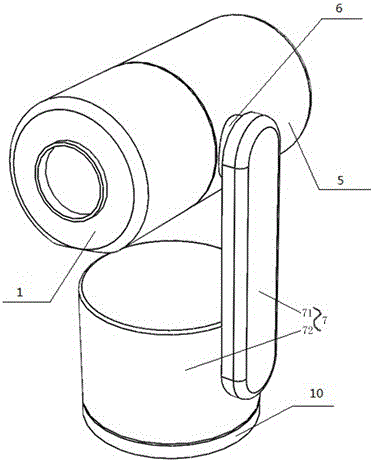

[0035] as attached image 3 , 4 As shown in and 5, the present invention discloses a three-axis cloud platform, comprising a base 10, a roll axis motor 4, a pitch axis motor 6 and a pan axis motor 9, and the pan axis motor 9 is installed on the base 10, the base 10 is equipped with a third connecting piece 7, the third connecting piece 7 is provided with a second control module 8, the second control module 8 is connected with the yaw axis motor 9, and the yaw axis motor 9 drives the third connecting piece 7 to rotate in a circle The pitch axis motor 6 is installed on the third connecting piece 7, and the pitching axis motor 6 is also equipped with the second connecting piece 5, and the pitch axis motor 6 drives the second connecting piece 5 to rotate in a circle; the rolling axis motor 4 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com