Device and method of measuring film strain and thermal conductivity

A technology of thermal conductivity and thin film, applied in the field of MEMS device devices of micro-electromechanical systems, can solve the problems of complex, unsatisfactory, and incomparable devices, and achieve the effects of easy operation, simple structure, mature and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

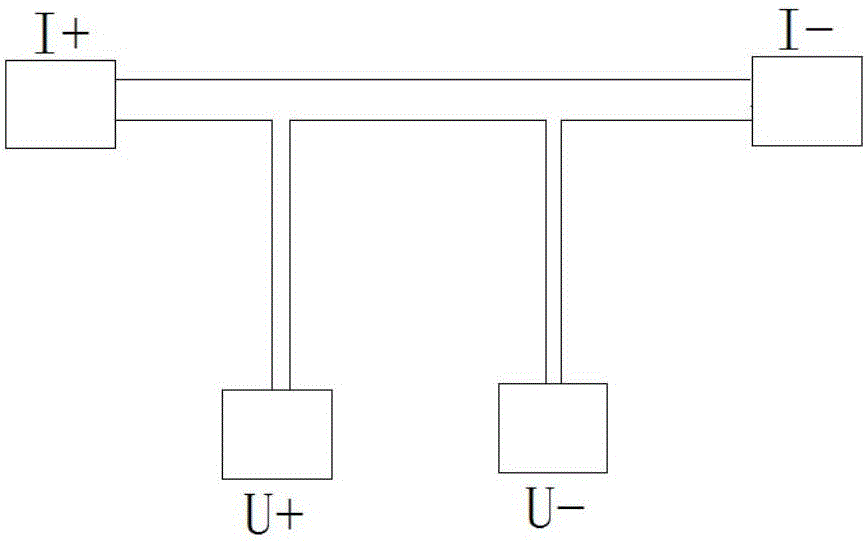

[0031] Such as figure 1 , figure 2 Shown in (a)-(c), the device for measuring thin film strain and thermal conductivity of the present invention includes a base 3, a shell 2 arranged on the base 3, the base 3 is provided with a loading end 6, coated with a thin film The substrate 5 is placed on the loading end 6 and connected to the simply supported fixed end 4 on the upper part of the housing 2, a precision guide rod 7 is provided under the loading end 6, and a test electrode and a metal plate are sputtered on the substrate 5 coated with a thin film. The test electrode is connected to the detection system with an external lock-in amplifier module and connected to the computer; the precession displacement S of the precision guide rod 7 makes the film on the substrate 5 coated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com