Tension control optimization method during welding tail swinging of cold-rolling strip steel

A technology for tension control and cold-rolled strip steel, applied in the direction of tension/pressure control, etc., can solve problems such as inability to optimize tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

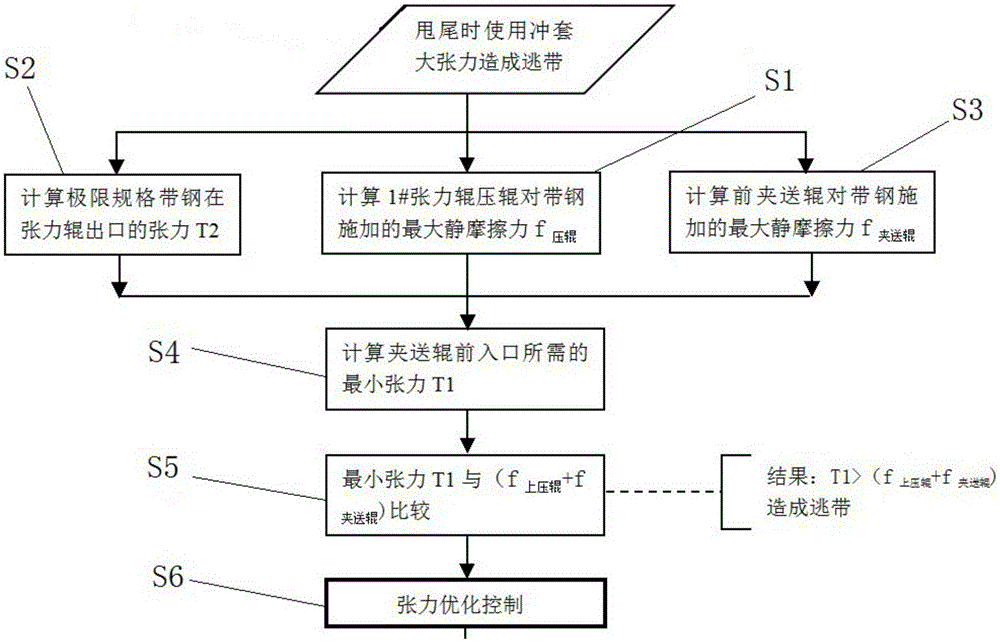

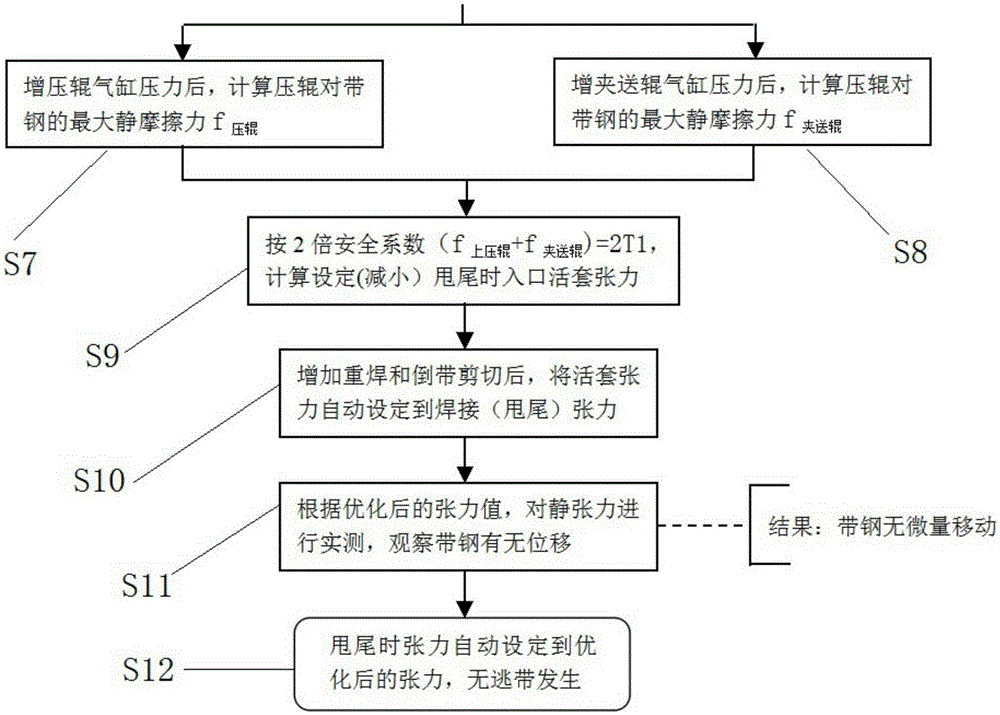

[0034] refer to Figure 2A and 2B , the present invention discloses a tension control optimization method for cold-rolled strip welding tailing. The problem to be solved is the strip escape problem caused by the high tension of the punching sleeve when the rolling mill is tailing. It can be mainly realized by the following steps.

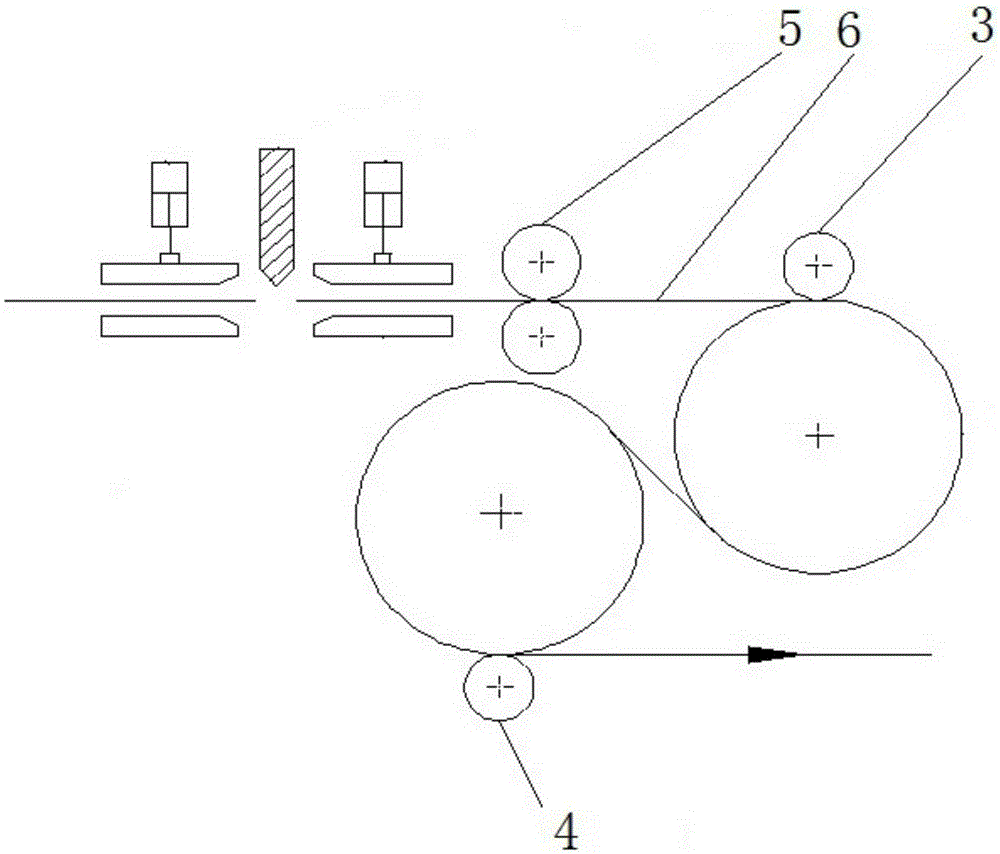

[0035] First, calculate the maximum static friction force after the tension roller and the pinch roller 5 place the cylinder action of the pressure roller to exert pressure on the strip 6. This step can be subdivided into S1-S3.

[0036] S1: Calculate the maximum static friction force f exerted by the 1# tension roller on the strip 6 压辊 .

[0037] S2: Calculate the tension T2 of the strip steel 6 of the limit specification at the exit of the tension roller.

[0038] S3: The maximum static frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com