Camera shooting direct-reading water meter with automatic decontamination function and automatic decontamination method

An automatic and functional technology, which is applied in the direction of measuring devices, instruments, liquid/fluid solid measurement, etc., can solve the problems of direct reading of water meters that are limited by camera, easy to be stained, and cannot be read, so as to improve the shooting effect and ensure the accuracy And the effect of reliability and convenience for normal observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

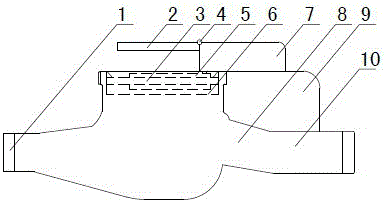

[0058] Figure 1-8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1-8 The present invention will be further described.

[0059] Such as figure 1 As shown, a camera direct-reading water meter with an automatic decontamination function includes a watch case 8, a water inlet 1 and a water outlet 10 are respectively arranged at both ends of the watch case 8, and the top of the watch case 8 is the water meter. Display window, the display window of the watch case 8 includes a reading panel 6 located in the watch case 8 and a cover 3 located at the port of the reading buckle, through which the numbers displayed in the reading panel 6 can be observed.

[0060] A power supply box 9 is fixed above the water outlet 10 of the watch case 8, the upper end surface of the power supply box 9 is flush with the display window of the watch case 8, and an execution box 7 is fixed on the upper surface of the power supply box 9, inside the power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com