A combined rotary disk extraction tower

A technology of a turntable extraction tower and a turntable, which is applied in the field of a combined turntable extraction tower, can solve problems such as the up and down vibration of a large turntable, and achieve the effects of reducing installation and maintenance costs, improving mass transfer efficiency, and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

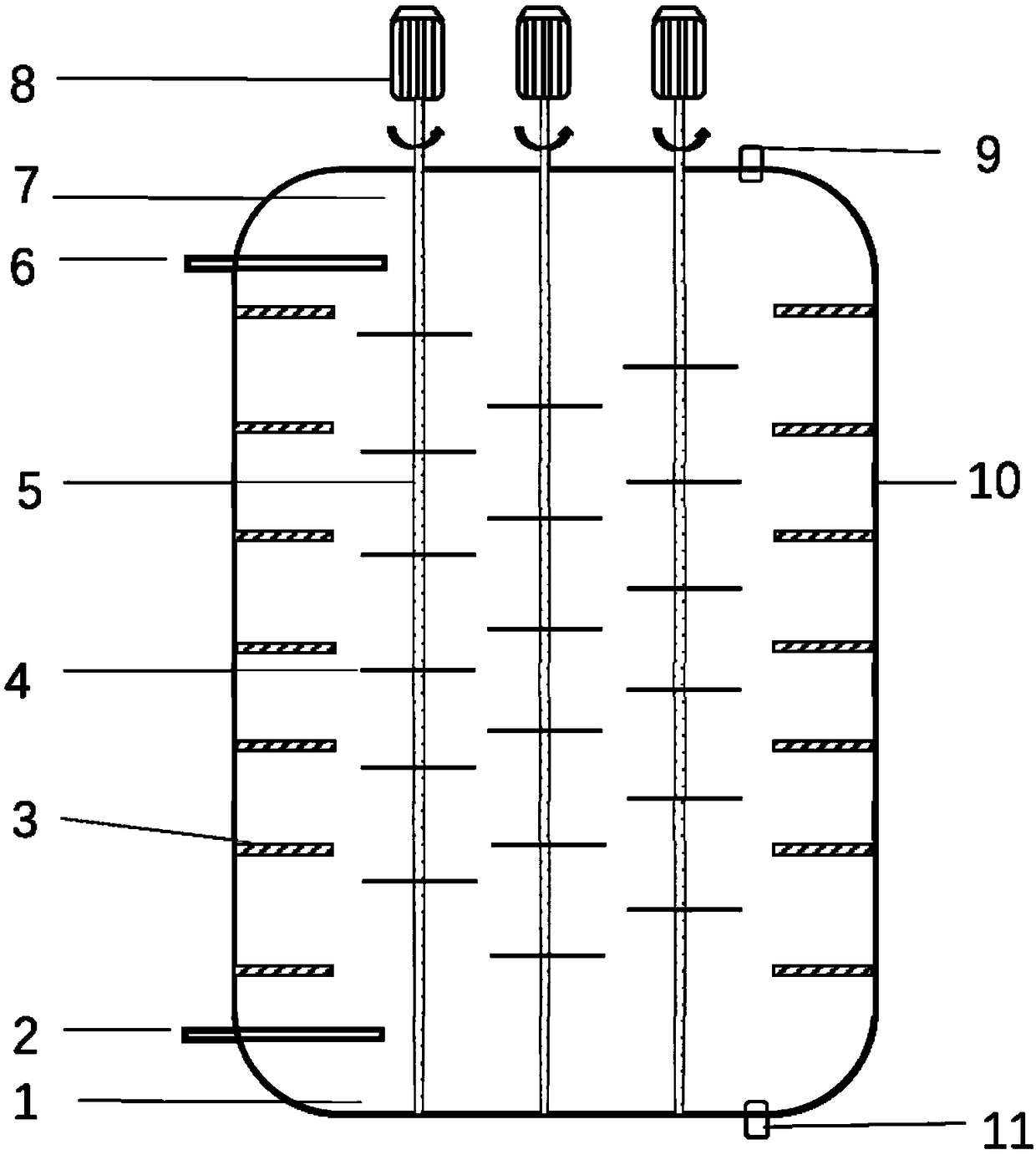

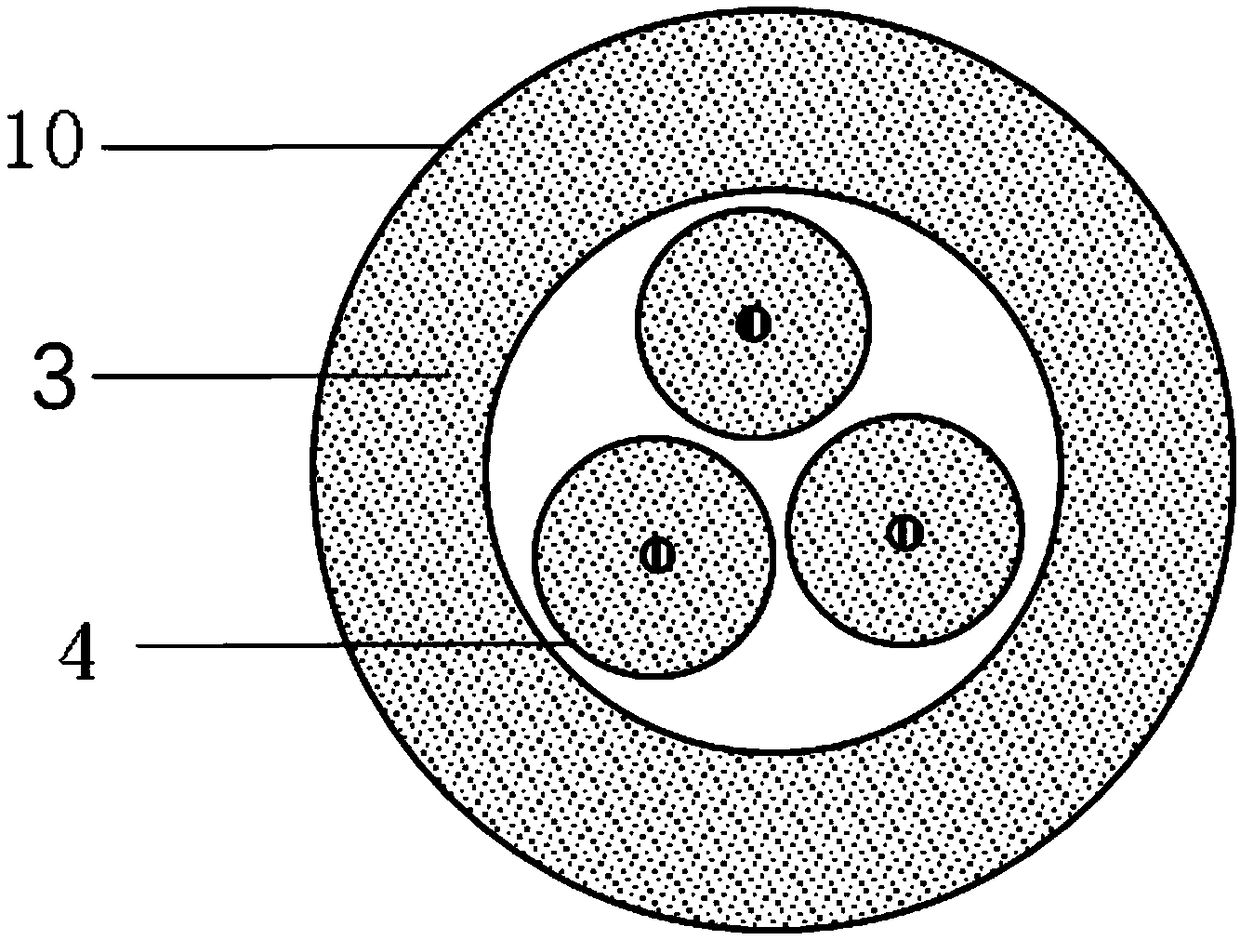

[0021] Such as figure 1 , figure 2 As shown, this embodiment provides a combined rotary disk extraction tower, which includes a tower body 10, a plurality of tower chambers are arranged in the tower body 10, and a plurality of turntables 4 are arranged in each tower chamber.

[0022] In this embodiment, the rotation of the large turntable in the tower chamber is replaced by a combination of multiple small turntables 4, which can solve the problem of up and down oscillations when the large turntable rotates in the prior art, and the energy utilization efficiency is higher, which provides a great advantage for the enlargement of the tower. important basis. The small turntable 4 here is that only one turntable is arranged in one tower chamber of the extraction tower with the same volume in the prior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com