Cable construction device

A construction device and cable technology, applied in cable laying equipment and other directions, can solve the problems of concentrated force distribution, low cable construction efficiency, large distribution density of guide wheels, etc., and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

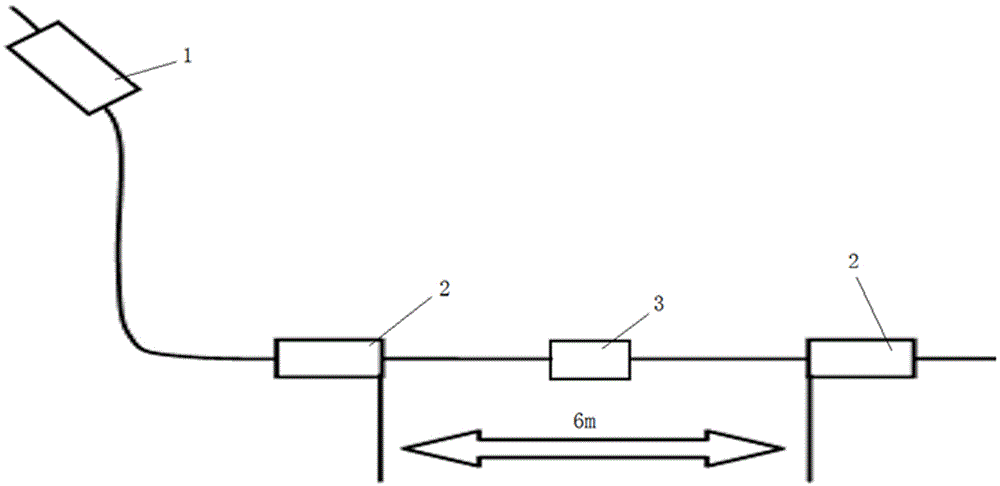

[0017] Such as figure 1 As shown, a cable construction device includes: a conveyor 1, at least two electric guide wheels 2 connected to the conveyor 1, and roller assemblies 3 alternately arranged between adjacent electric guide wheels 2; The cable 4 passes through the roller assembly 3 and adheres to the surface of the electric guide wheel 2 , and is transported by the conveyor 1 .

[0018] The distance between every two adjacent electric guide wheels 2 is 5-7m, and the distance in this embodiment is 6m.

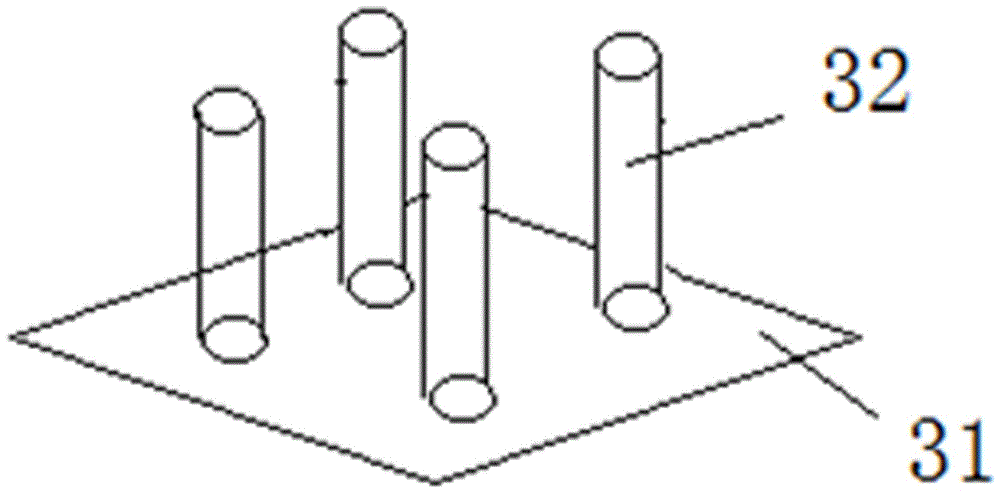

[0019] Such as figure 2 As shown, the roller assembly 3 includes: a base 31 ; several pairs of rollers 32 vertically spaced on the base 31 , and the cable 4 is driven on the surface of each pair of rollers 32 . The roller 32 is a rubber roller. The base is made of aluminum alloy.

[0020] Considering tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com