Embedded type rapid wiring structure

A wiring structure, embedded technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problem of the closing of the wiring shrapnel, easy to be accidentally triggered, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

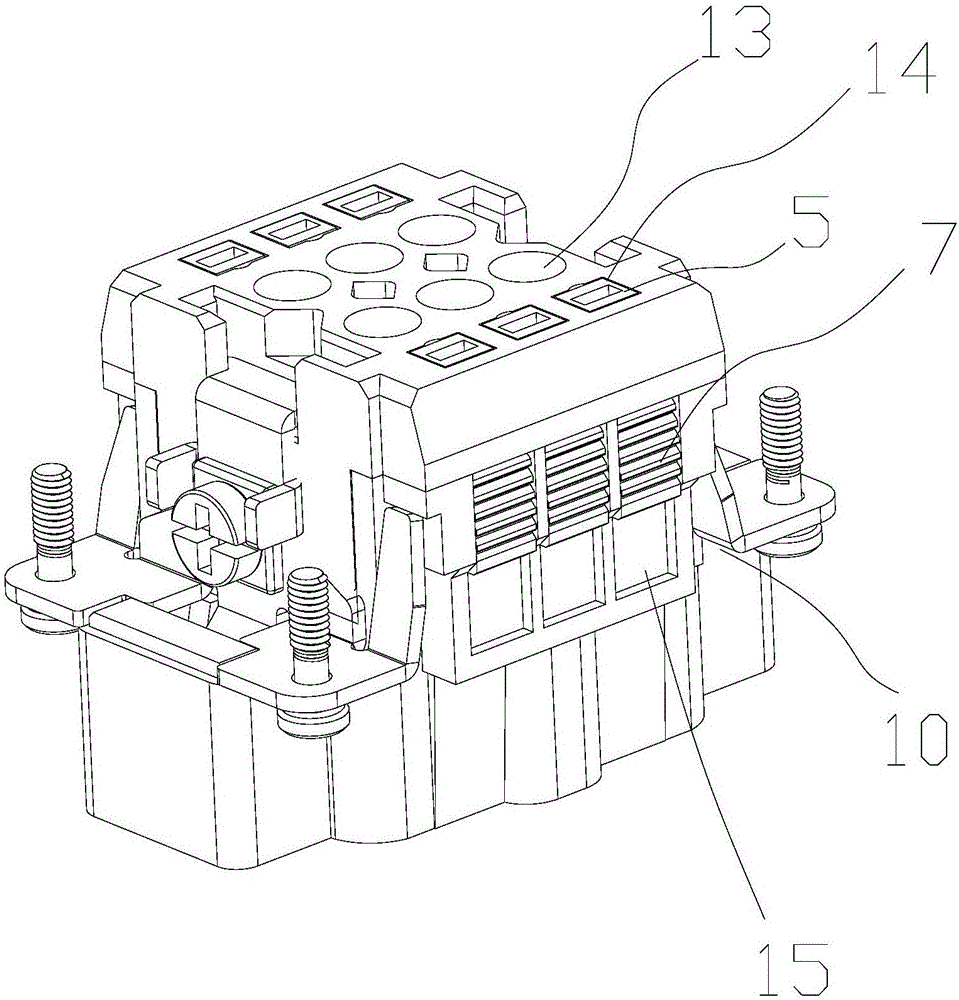

[0032] combine figure 1 As shown, the embedded quick wiring structure of this embodiment includes a wire socket 10, and the wire socket 10 is provided with 6 sets of wiring assemblies ( figure 1 not visible, see figure 2 Parts marked as 2 / 3 / 4), corresponding to each group of wiring components, a wiring hole 13 is provided on the terminal block 10, and a sliding switch 5 is also movably installed on the terminal block 10 corresponding to each wiring component. In the embodiment, there are six slide switches 5, which are equally divided into two rows and installed on both sides of the terminal block 10 .

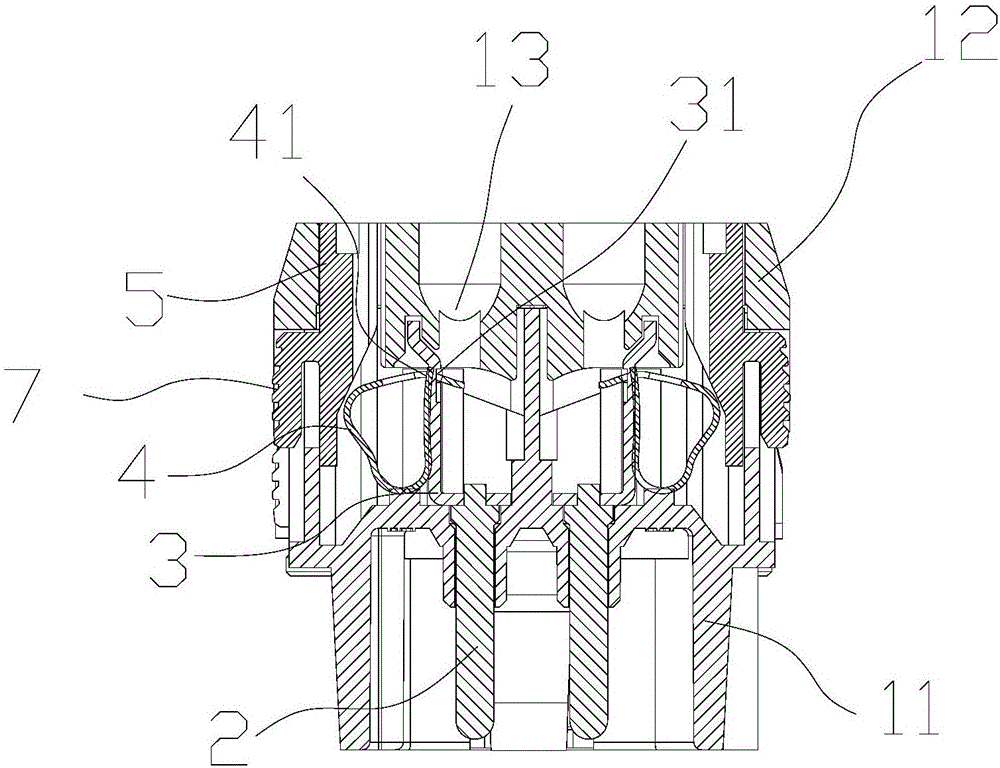

[0033] recombine figure 2 :

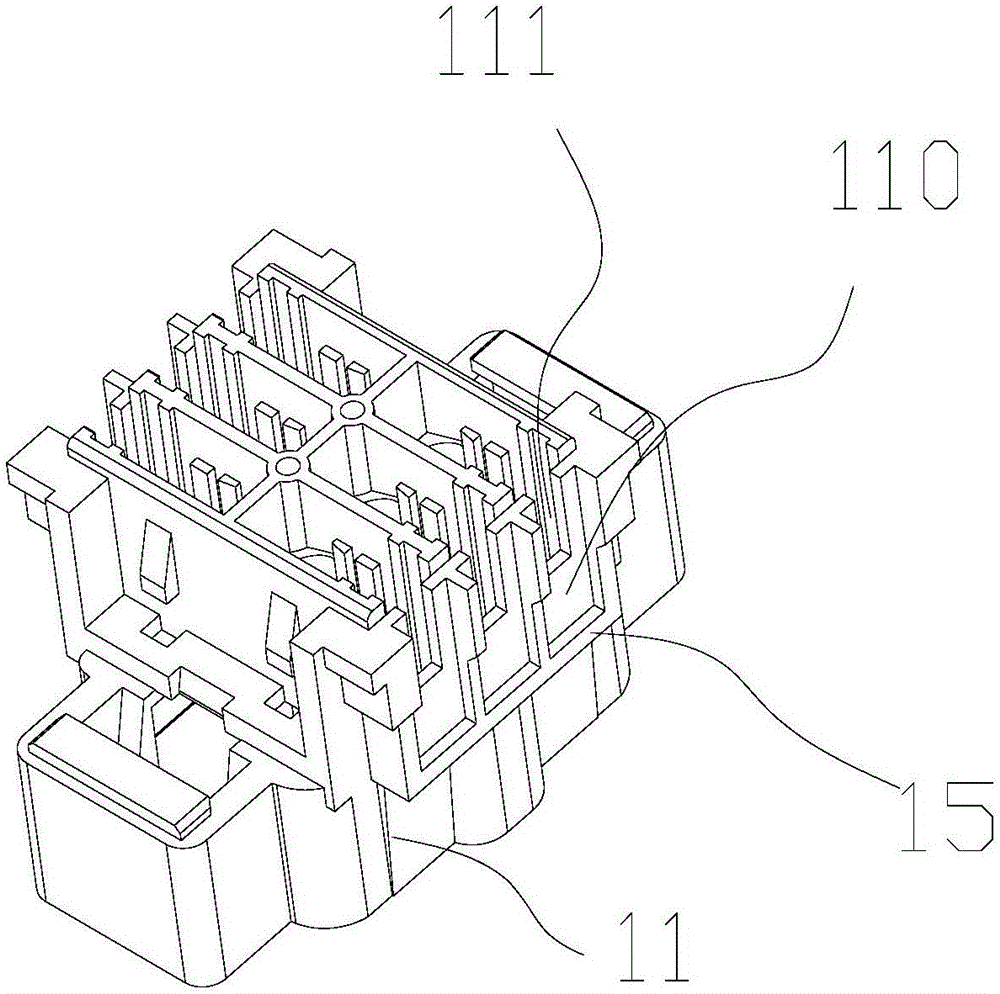

[0034] The terminal block 10 includes an insulator body 11 and an insulator cover 12, the insulator cover 12 is fastened and fixed on the insulator body 11; the wiring hole 13 is opened on the insulator cover 12, and corresponds to each The wiring holes 13 and the insulator main body 11 are correspondingly installed with a wiring assembly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com