A kind of preparation method and application of hollow graphene fiber electrode

A graphene fiber and graphene technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of long preparation time and complicated steps, and achieve the effect of fast and controllable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

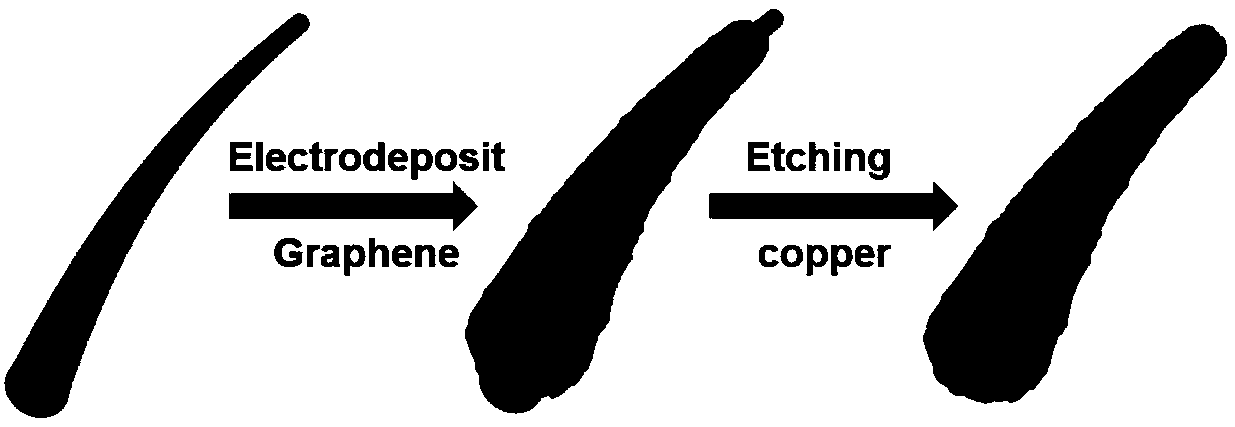

[0024] Preparation of hollow graphene fiber electrodes:

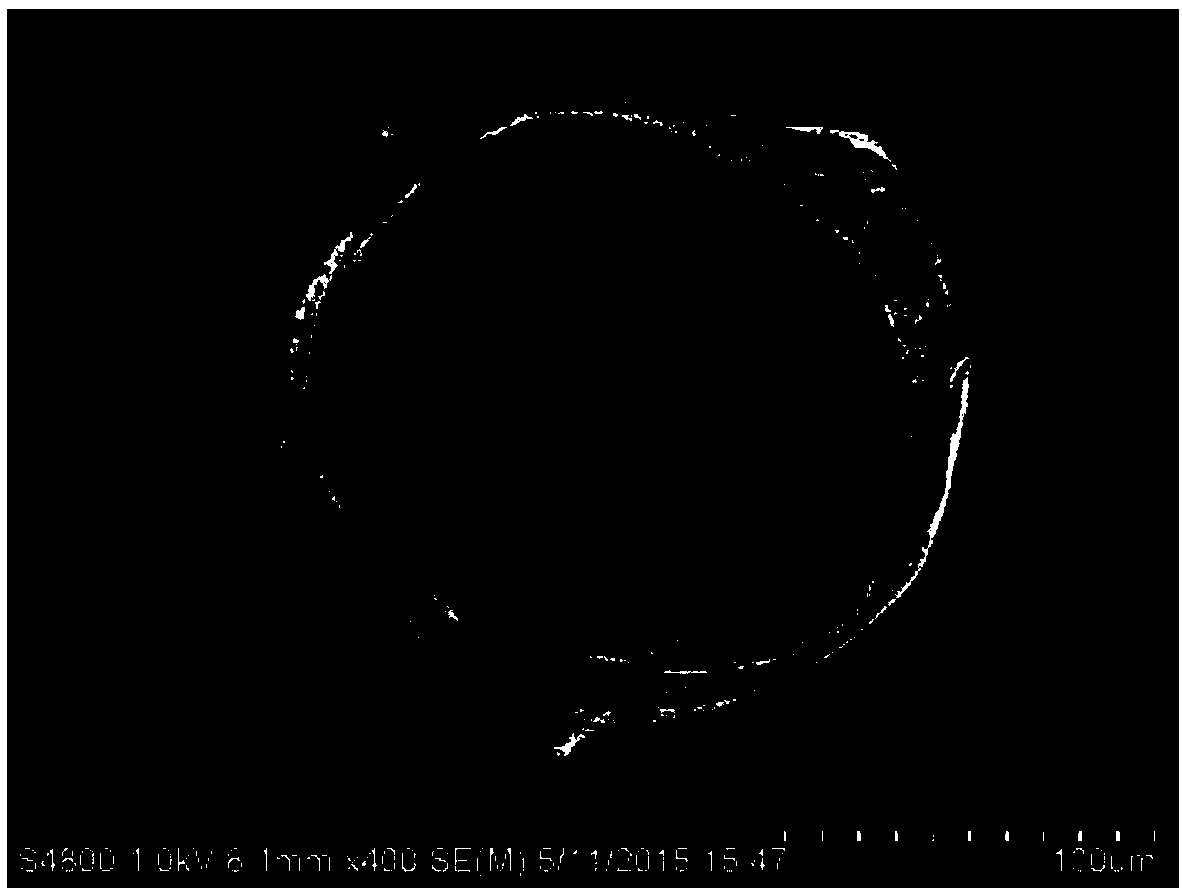

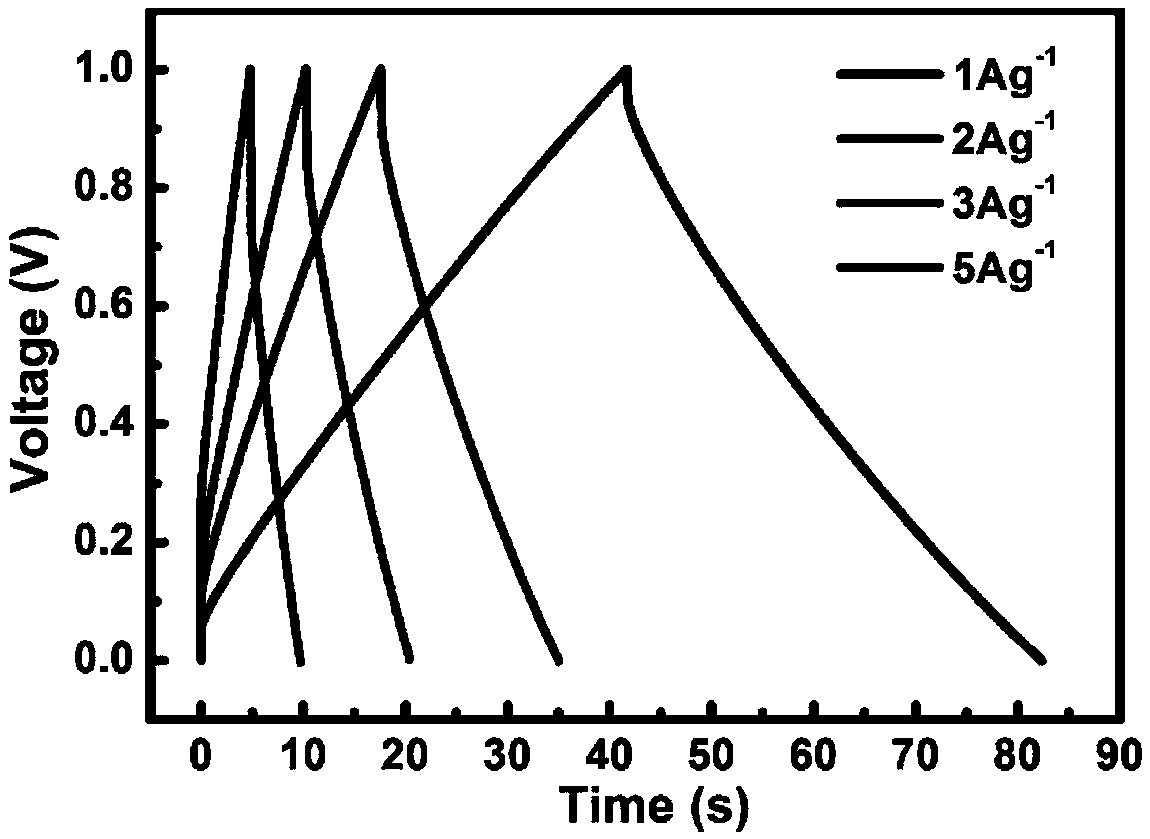

[0025] First, 100 mL of a 3 mg / mL graphene oxide aqueous solution was prepared by a chemical oxidation exfoliation method. Weigh 1.06g of lithium perchlorate, add it into 100mL of graphene oxide aqueous solution and stir to dissolve for 1h to obtain a precursor mixed solution. A copper wire with a diameter of 100 μm was used as the working electrode, a saturated potassium chloride electrode was used as the reference electrode, and a platinum wire electrode was used as the counter electrode to construct an electrochemical deposition reduction system. Put the above electrochemical reduction system into the graphene oxide mixed solution, and apply a constant voltage of -1.2V between the working electrode and the reference electrode. The deposition reduction time is 180s. Under the action of the electric field, the graphene oxide sheet will Adsorbed on the surface of copper wire electrode and electrochemically reduced to g...

Embodiment 2

[0029] Preparation of hollow graphene fiber electrodes:

[0030] First, 100 mL of a 5 mg / mL graphene oxide aqueous solution was prepared by a chemical oxidation exfoliation method. Weigh 2.12g of lithium perchlorate, add it into 100mL graphene oxide aqueous solution and stir and dissolve for 1h to obtain a precursor mixed solution. An iron wire with a diameter of 500 μm was used as the working electrode, a saturated potassium chloride electrode was used as the reference electrode, and a platinum wire electrode was used as the counter electrode to construct an electrochemical deposition reduction system. Put the above electrochemical reduction system into the graphene oxide mixed solution, and apply a constant voltage of -1.2V between the working electrode and the reference electrode, and the deposition reduction time is 60s. Under the action of the electric field, the graphene oxide sheet will Adsorbed on the surface of copper wire electrode and electrochemically reduced to g...

Embodiment 3

[0034] Preparation of hollow graphene fiber electrodes:

[0035] First, 100 mL of a 1 mg / mL graphene oxide aqueous solution was prepared by a chemical oxidation exfoliation method. Weigh 0.53 g of lithium perchlorate, add it into 100 mL of graphene oxide aqueous solution and stir to dissolve for 1 h to obtain a precursor mixed solution. An aluminum wire with a diameter of 50 μm was used as a working electrode, a saturated potassium chloride electrode was used as a reference electrode, and a platinum wire electrode was used as a counter electrode to construct an electrochemical deposition reduction system. Put the above electrochemical reduction system into the graphene oxide mixed solution, and apply a constant voltage of -1.2V between the working electrode and the reference electrode. The deposition and reduction time is 300s. Under the action of the electric field, the graphene oxide sheet will Adsorbed on the surface of copper wire electrode and electrochemically reduced t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com