Display panel and preparing method of optical film of display panel

A technology of optical film and display device, applied in optics, optical components, optomechanical equipment, etc., can solve problems such as limited improvement, complicated optical film manufacturing process, and poor perception at large viewing angles, and achieve simple structure and improvement of poor perception at large viewing angles , Best glasses-free 3D and dual-vision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

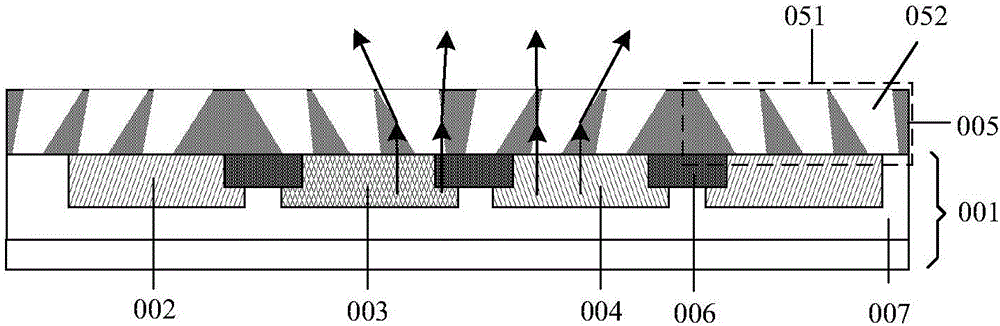

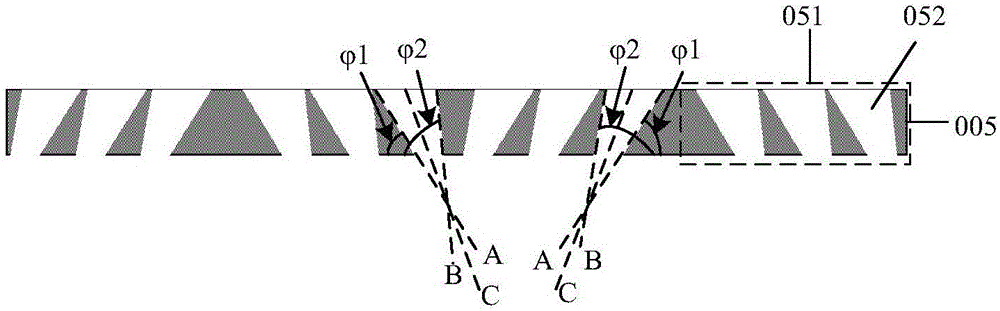

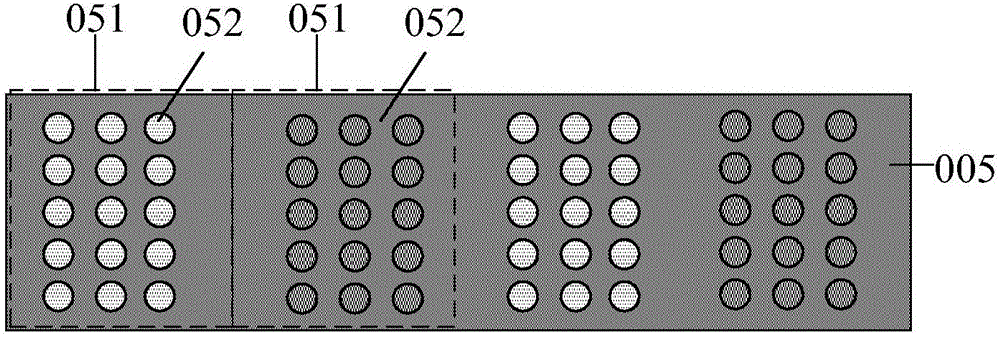

[0037] In order to solve the above technical problems, embodiments of the present invention provide a display device and a method for manufacturing an optical film therein. A display device provided by an embodiment of the present invention includes a display panel, a plurality of sub-pixels disposed in a matrix on the display panel, and an optical film disposed on the light-emitting side of the display panel; the body of the optical film is provided with multiple pixels distributed in a matrix. A group of hole structures; each group of hole structures corresponds to a sub-pixel setting; wherein, each group of hole structures has through holes that are inclined in the same direction relative to the plane of the optical film body, and the openings of the through holes gradually increase from the light-incoming side to the light-outgoing side , on a section along the side of the display device and perpendicular to the main body of the optical film, the angle between the first sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com