On-line flaw detection device of wind generating set

A technology for wind turbines and flaw detection devices, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, and materials, etc., can solve the problems of great influence, difficulty in detecting wind turbines, and low efficiency, and achieve rapid flaw detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

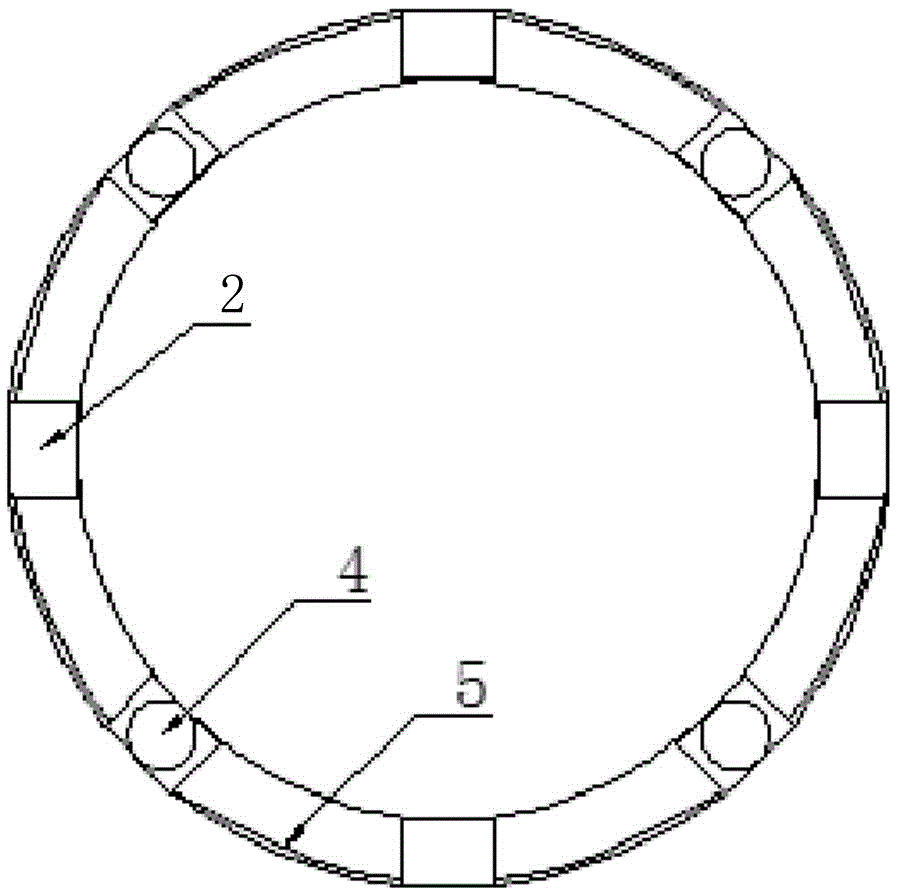

[0045] The present invention provides an online flaw detection device for a tower of a wind power generating set. The device includes an electromagnetic vertical climbing robot 1, a circumferential movement and circumferential adjustment robot 2 and a flaw detector 4. The electromagnetic vertical climbing robot 1 is connected to the circumferential movement and The circumferential adjustment robot 2, the circumferential movement and the circumferential adjustment robot 2 are connected to the flaw detector 4.

[0046] There are multiple flaw detectors 4 arranged along the circumferential direction of the object to be tested, and a circular movement and circumferential adjustment robot 2 is connected between two adjacent flaw detectors 4 .

[0047] The flaw detector 4 is connected with the robot 2 for circumferential movement and circumferential adjustment through an arc-shaped rack 5 .

[0048] The electromagnetic vertical climbing robot 1 is connected with the robot 2 for circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com