Pile-soil interface shear test device

A technology of shear test and contact surface, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problem of inability to obtain accurate relative displacement relationship between pile and soil, regardless of the displacement of soil around the pile, Problems such as different friction characteristics of pile-soil contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

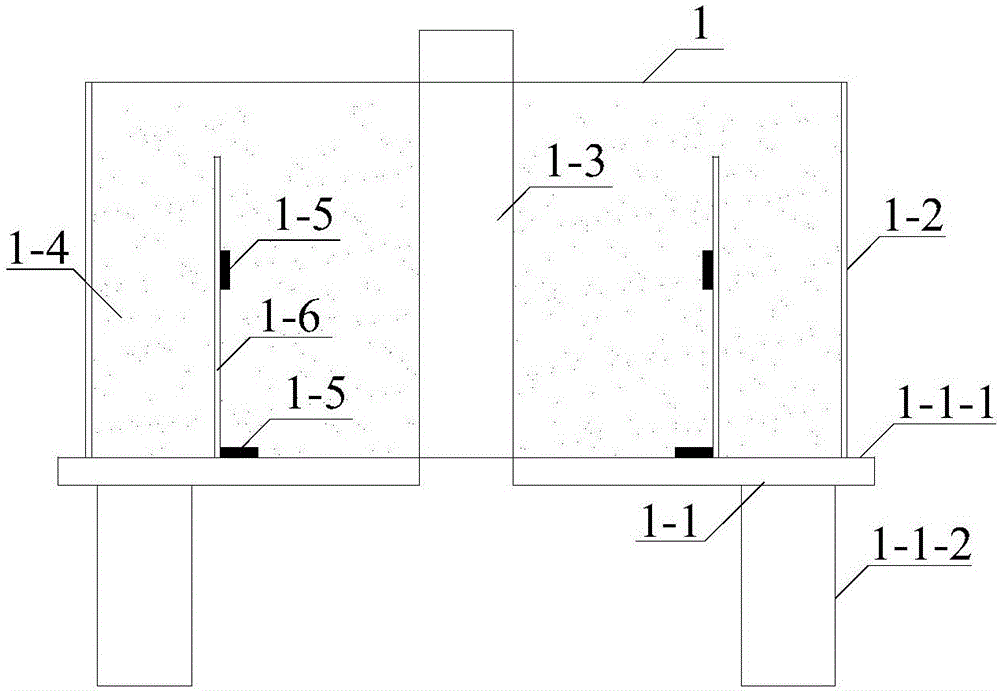

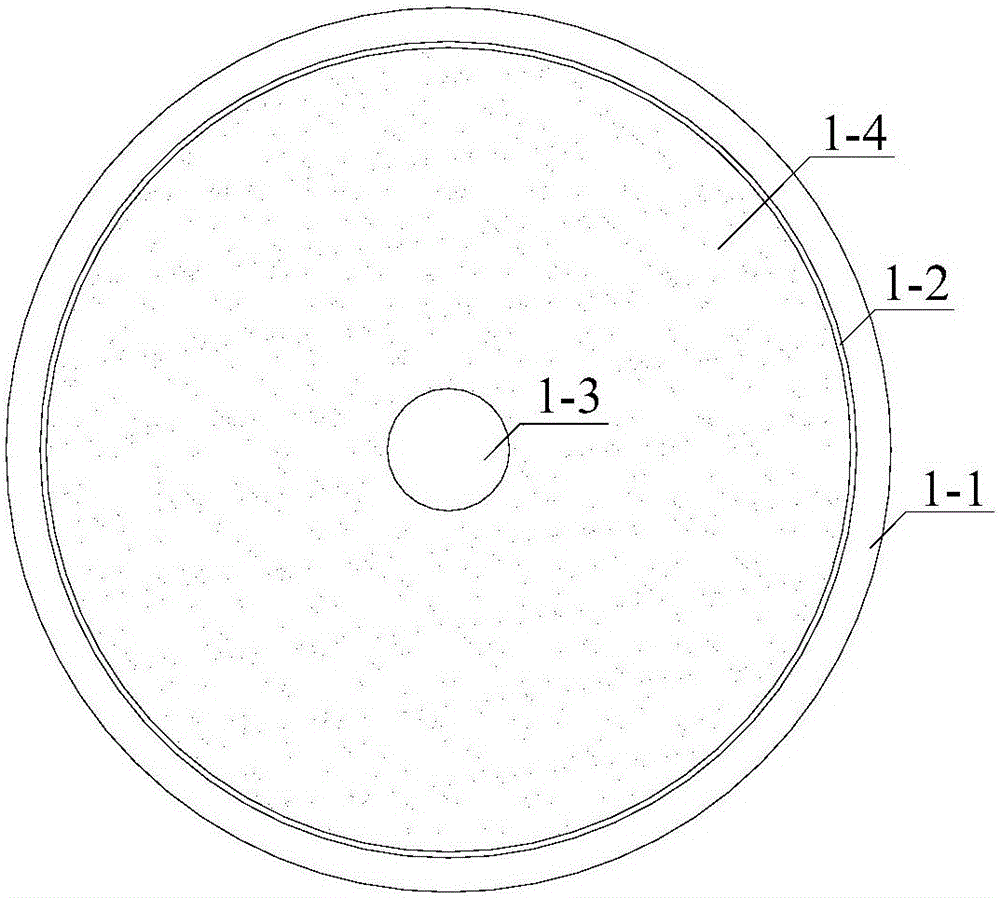

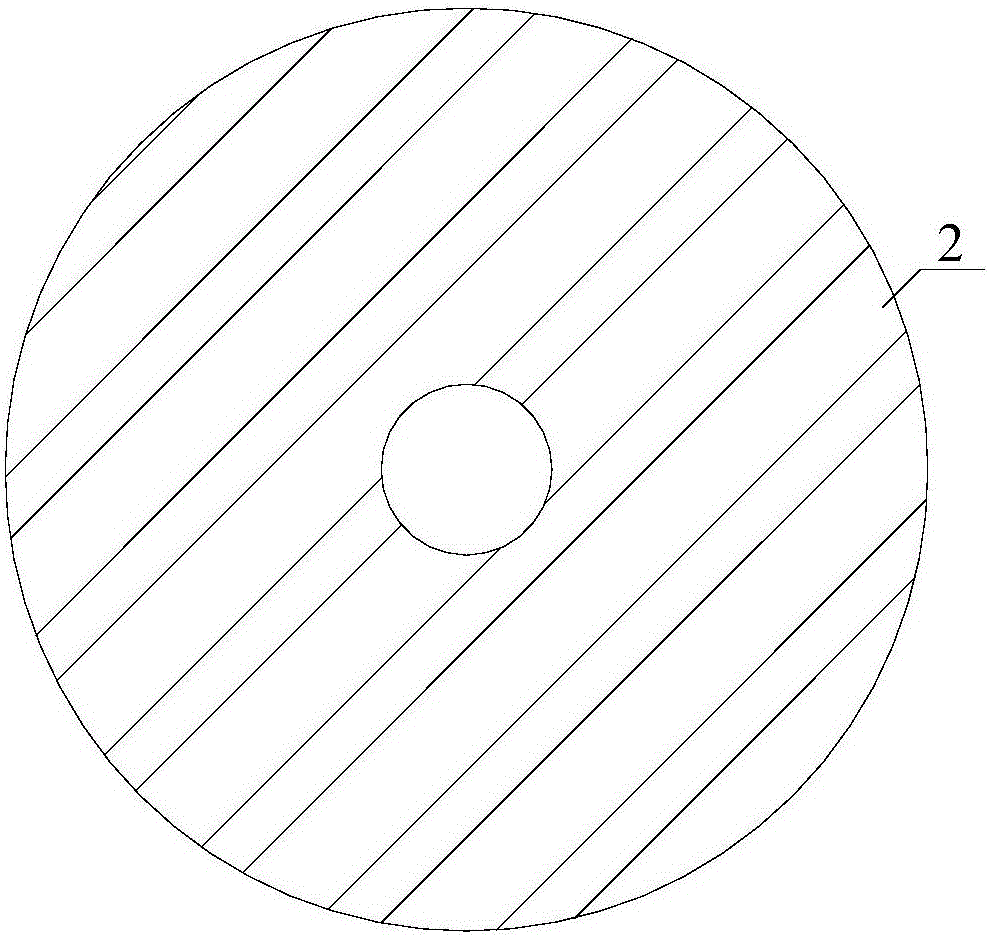

[0026] Such as figure 1 , Figure 4 As shown, the present invention is a pile-soil contact surface shear test device capable of simulating different sand density and different overlying pressures, including a circular model box 1, a loading plate 2, a reaction beam 3 and a servo loading device 4 in four parts.

[0027] Described circular model box 1 is made up of model box base 1-1 and circular model box frame 1-2; Described model box base 1-1 bottom plate 1-1-1 and support 1-1-2 are formed, bottom plate 1-1-1 is welded on the support 1-1-2; the base plate 1-1-1 is a 30mm thick steel plate with a diameter of 1000mm, and a round hole is provided at the center of the base plate; the support 1-1 -2 is welded by I-beam, with a height of 600mm; the circular model box frame 1-2 is made of 10mm thick steel plate, with a diameter of 900mm; the inside of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com