Durability testing device for test piece under load and environment coupling effect

A technology of durability test and test device, which is applied in the direction of measuring device, strength characteristics, instruments, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

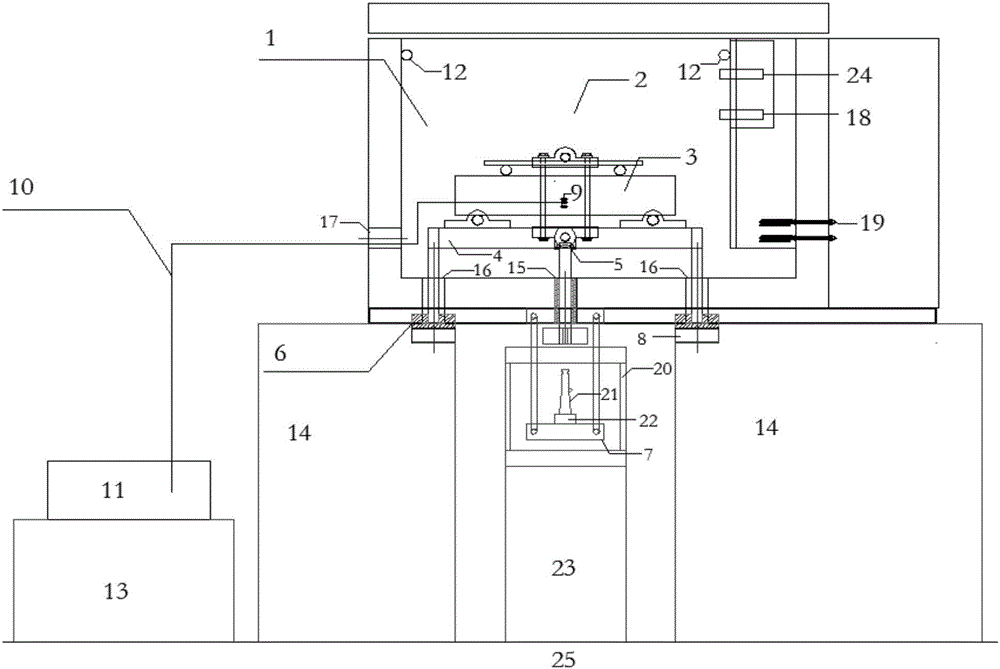

[0041] Example 1: Bending loading test on specimen under multi-factor environment

[0042] The durability test device for loading and testing the bending test members is as follows: figure 1 shown. The specific implementation steps are:

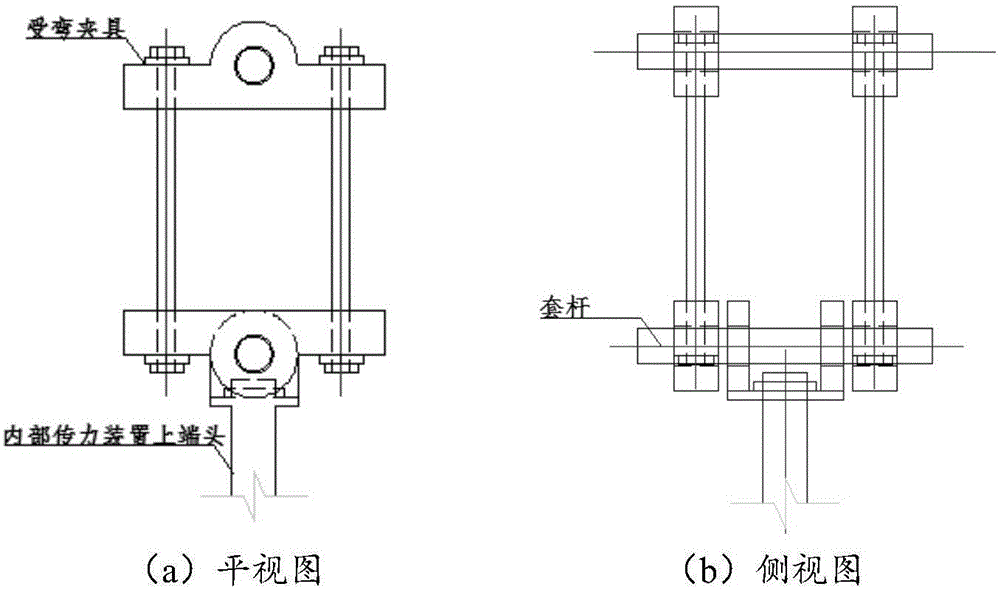

[0043] (1) Set the bending test piece 3 with 2 bending loading fixtures. For details of the bending loading fixtures, see image 3 . The data measurement and recording device 1 is arranged on the test piece 3 , and the corresponding test leads 10 protrude through the holes 17 and are connected with the data measurement and recording system 11 . Open the working cabin 1 of the test device, place the bending test piece 3 and the loading fixture 2 in the designated position in the working cabin 1; (2) connect the loading fixture 2 and the upper end of the internal force transmission device 5 through a sleeve rod (see Figure 5 ), close the working cabin 1; (3) open the jack 21, adjust the lifting force of the jack 21 according to the sensor ...

example 2

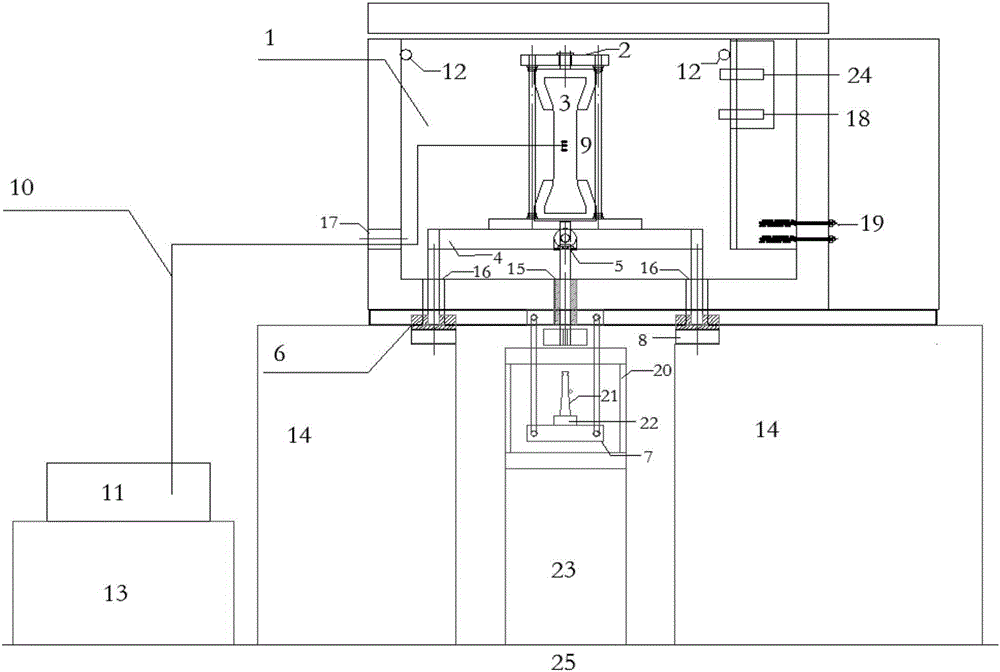

[0044] Example 2: Axial tensile loading test on test member under multi-factor environment

[0045] The durability test device for loading and testing the axial tension test members is as follows: figure 2 shown. The specific implementation steps are:

[0046] (1) Set the axial tension test piece 3 with two axial tension loading fixtures. For details of the axial tension loading fixture, see Figure 4 . The data measurement and recording device 1 is arranged on the test piece 3 , and the corresponding test leads 10 protrude through the holes 17 and are connected with the data measurement and recording system 11 . Open the working cabin 1 of the test device, place the bending test piece 3 and the loading fixture 2 in the designated position in the working cabin 1; (2) connect the loading fixture 2 and the upper end of the internal force transmission device 5 through a sleeve rod (see Figure 5 ), close the working cabin 1; (3) open the jack 21, adjust the lifting force of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com