Lubricating device of drill rod

A technology for lubricating devices and drill pipes, which is applied in the direction of engine lubrication, distribution devices, lubricating parts, etc., can solve the problems of inconvenience and time-consuming, and achieve the effects of saving time, reducing costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

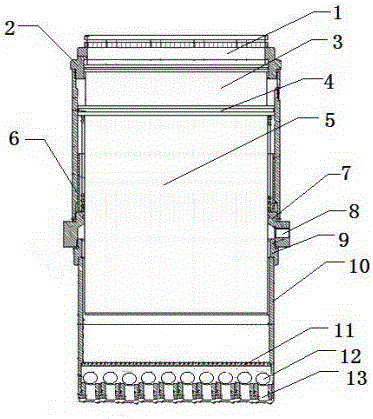

[0012] This embodiment provides a lubricating device for drill pipes, which is characterized in that: the lubricating device for drill pipes includes an adjusting compass (1), a fixed ring (2), an adjusting core (3), a piston (4), a piston barrel (5), upper cylinder barrel (6), upper connecting ring (7), threaded oil outlet (8), lower connecting ring (9), lower cylinder barrel (10), baffle plate (11), steel ball ( 12), oil channel (13);

[0013] Among them: including the upper cylinder (6) and the lower cylinder (10), the lower end of the upper cylinder (6) is connected to the lower cylinder (10) through the upper connecting ring (7) and the lower connecting ring (9), and the upper connecting ring (7) There is a threaded oil outlet (8) on one side, the piston barrel (5) runs through the upper cylinder barrel (6) and the lower cylinder barrel (10), the upper end of the piston barrel (5) is the piston (4), and the piston (4) ) is connected to the adjustment core (3), and a fixe...

Embodiment 2

[0016] This embodiment provides a lubricating device for drill pipes, which is characterized in that: the lubricating device for drill pipes includes an adjusting compass (1), a fixed ring (2), an adjusting core (3), a piston (4), a piston barrel (5), upper cylinder barrel (6), upper connecting ring (7), threaded oil outlet (8), lower connecting ring (9), lower cylinder barrel (10), baffle plate (11), steel ball ( 12), oil channel (13);

[0017] Among them: including the upper cylinder (6) and the lower cylinder (10), the lower end of the upper cylinder (6) is connected to the lower cylinder (10) through the upper connecting ring (7) and the lower connecting ring (9), and the upper connecting ring (7) There is a threaded oil outlet (8) on one side, the piston barrel (5) runs through the upper cylinder barrel (6) and the lower cylinder barrel (10), the upper end of the piston barrel (5) is the piston (4), and the piston (4) ) is connected to the adjustment core (3), and a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com