Test bed and method for simulated working condition of multistage hydraulic cylinder

A technology of test bench and hydraulic cylinder, which is applied in the testing of fluid pressure actuation system, fluid pressure actuation device, mechanical equipment, etc. Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

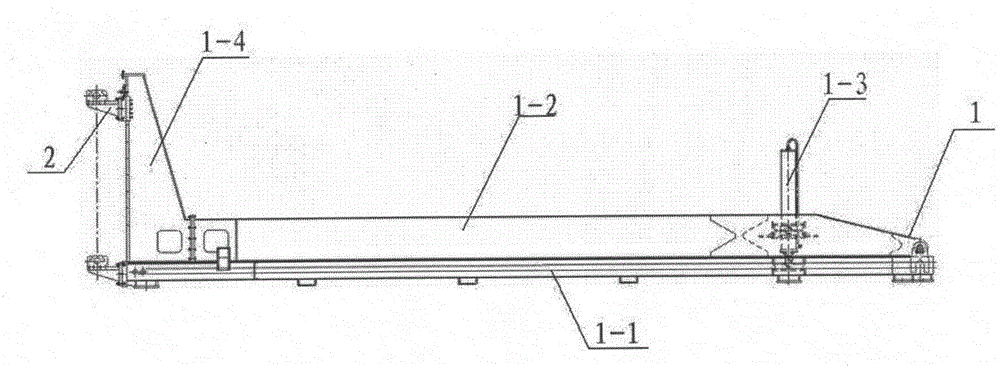

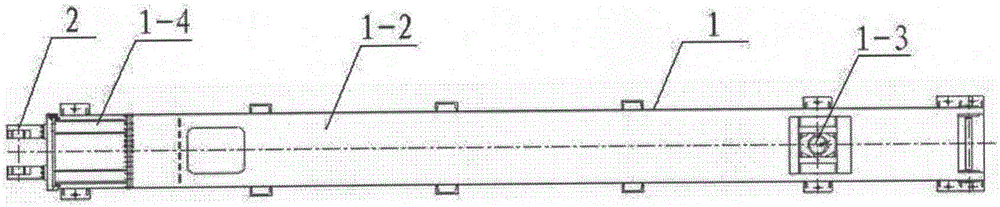

[0026] Such as Figure 1-4 As shown, it is a multi-stage hydraulic cylinder simulated working condition test bench provided by the present invention, which particularly includes a simulated working condition running bench 1, and the simulated working condition running bench 1 includes a fixed frame 1-1 and a movable frame 1-2, the fixed frame 1-1 is movably connected with one end of the movable frame 1-2, and the movable frame 1-2 is provided with a cylinder 1-3 near the end, and the movable end of the cylinder 1-3 passes through the movable frame 1-2 is fixedly connected with the fixed frame 1-1; the other end of the fixed frame 1-1 and the movable frame 1-2 are respectively provided with an adjustment frame 2 for fixing the multi-stage hydraulic cylinder, and the end of the movable frame 1-2 Adjustment frame fixing seat 1-4 is provided at the top, and a plurality of adjustment frame mounting holes 1-5 are provided on the adjustment frame fixing seat 1-4. The adjustment fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com