An airborne advance support device that can be lifted, folded and extended

A technology of advanced support and lifting device, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of poor flexibility of advanced support and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

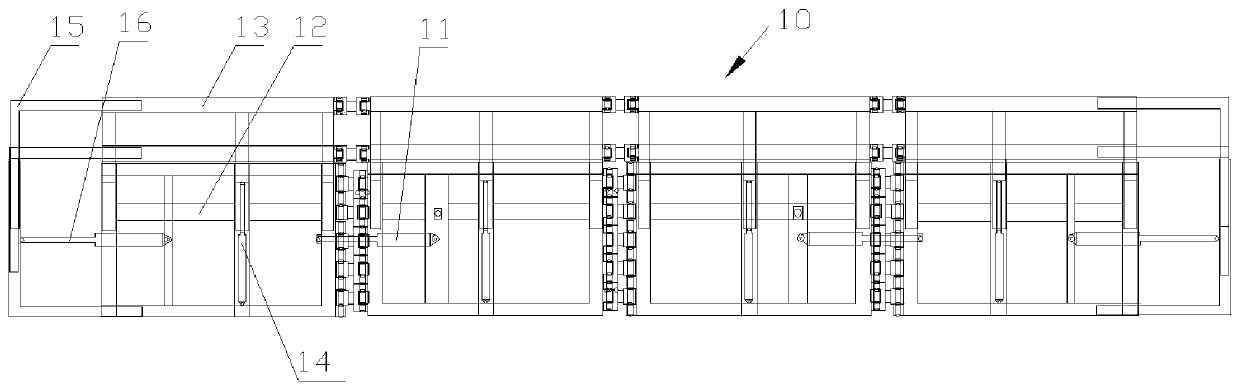

[0043] Such as figure 1 , figure 2 As shown, an airborne advance support device 1 that can be lifted, folded, and extended includes a plurality of support frames 10 that are sequentially hinged; the number of support frames 10 is generally an even number, which is convenient for left and right symmetrical folding. There are four support frames 10 provided by the present invention. From the middle to both sides, the first driving mechanism 11 drives two adjacent support frames 10 to expand or fold. That is to say, the two supporting frames 10 on the left are driven by a first driving mechanism 11, and the two supporting frames 10 on the right are driven by a first driving mechanism 11, and the left and right sides are mirror images.

[0044]The support frame 10 comprises a main frame 12 and a widening bracket 13 arranged on one side of the main frame 12; Stretch up. There are many ways of sliding and fixing, such as socketing and track sliding and fixing. The present inve...

Embodiment 2

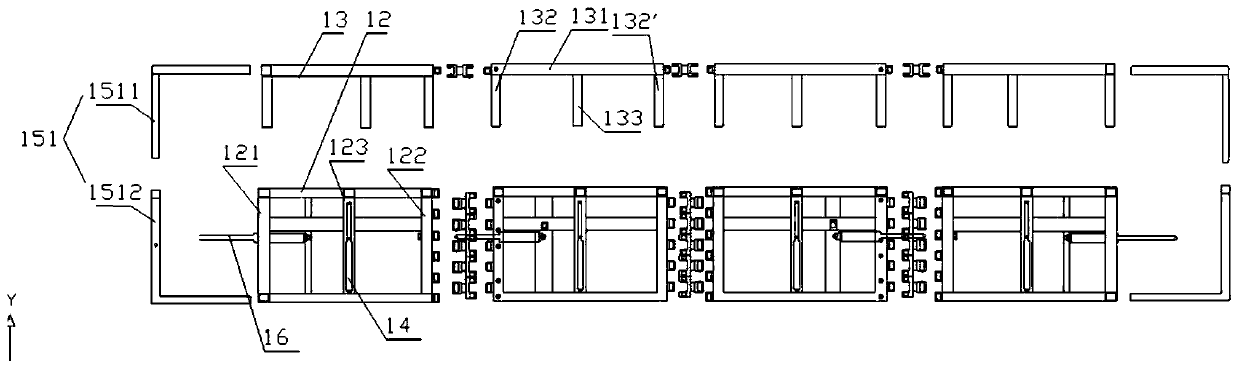

[0047] Such as image 3 , Figure 4 , Figure 5 As shown, in order to further increase the width of the advance support 1 , widening brackets 13 can be provided on both sides of the main frame 12 . The widening brackets 13 on both sides are a mountain-shaped structure arranged opposite to each other. Correspondingly, two second drive mechanisms 14 with opposite jacking directions are fixed inside the middle rod 123 ; In order to pack up, the overall volume of the advance support 1 is relatively small, the present invention adopts the lower surface spacing between the two left side bars 132 of one of the widening brackets 13 to be equal to the upper surface spacing between the two left side bars 132 of the other widening bracket 13. The characteristics of the surface spacing make the two widened brackets 13 folded together, and the left side bars 132 are overlapped together to reduce the volume. Of course, this requires that the inner cavity diameters of the left rod 121 an...

Embodiment 3

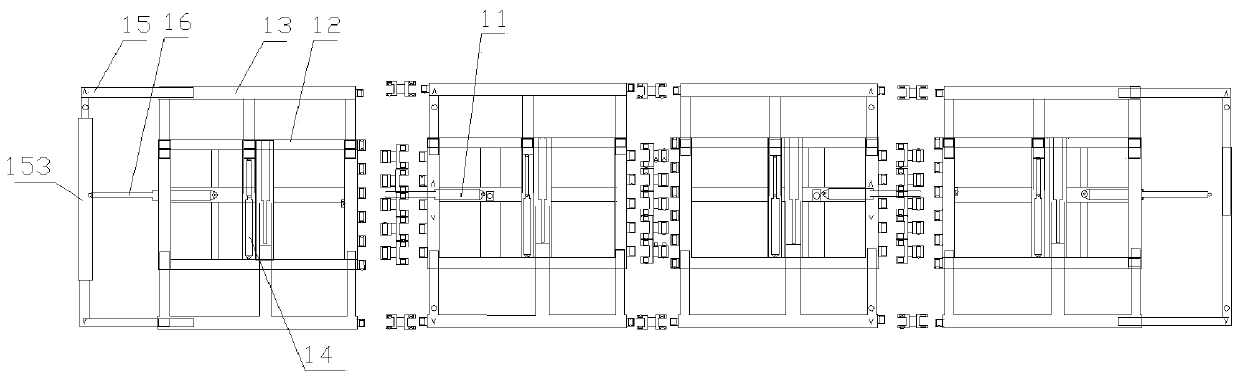

[0049] Such as figure 1 , figure 2 As shown, on the basis of Embodiment 1, an extension bracket 15 is also provided on the left side of the support frame 10 at the left end of the advance support 1 , and an extension bracket 15 is also provided on the right side of the support frame 10 at the right end. The extended bracket 15 is slidably fixed on the widened bracket 13 on the left end or the right end support frame 10 of the leading support 1, and the extended bracket 15 is driven to expand and contract by the third driving mechanism 16. Equally, there are many ways to slide and fix the extended bracket 15 and the widened bracket 13, which can be sleeved or rail-slidingly connected. The utility model adopts socket form, specifically:

[0050] The extended bracket 15 is a third frame body formed by a telescopic rod 151 and two parallel cross bars vertically fixed on the two ends of the telescopic rod 151; the bottom rod 131 of the widened bracket 13 on one side of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com