Tunnel construction method

A technology for tunnel construction and tunneling, which is applied in tunnels, earthwork drilling, blasting, etc., can solve problems such as large construction workload, and achieve the effect of improving construction efficiency and reducing construction workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The construction method adopted in the present invention is to utilize the tunnel boring machine to construct the middle part of the tunnel first, and then adopt methods such as drilling and blasting to construct the remaining parts; adopting this method to carry out construction has not only fully utilized the construction of the wire saw type roadheader At the same time, it provides favorable construction conditions for the construction of the remaining parts such as drilling and blasting.

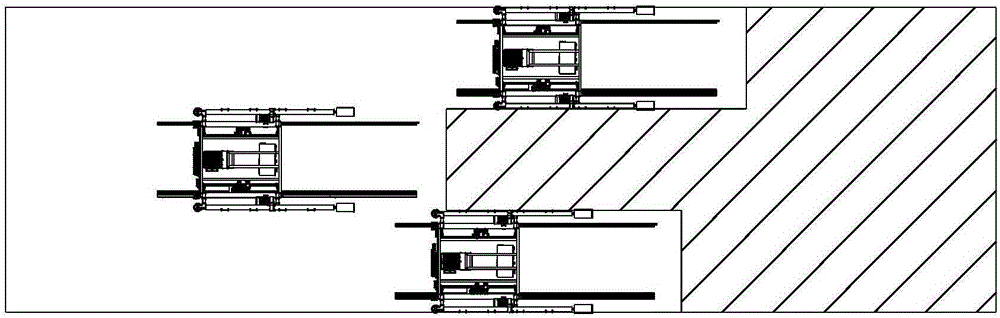

[0027] Such as figure 1 , in this embodiment, the middle part of the tunnel section is divided into six small rectangles of the same area as an example for illustration; the six small rectangles are divided into two layers, each layer includes three small rectangles, and each layer The three small rectangles are arranged side by side, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com