A fracturing method for artificial fractures with low damage and high conductivity in coalbed methane wells

A technology of artificial fractures and conductivity, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of poor conductivity of artificial fractures, low viscosity of active water, and inability to achieve the effect of increasing production. The effect of reducing reservoir damage, improving conductivity and improving construction success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

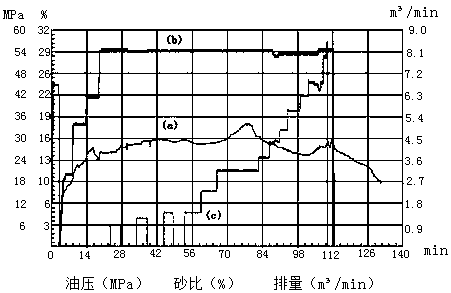

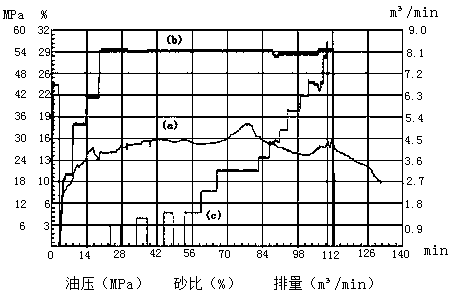

[0028] Such as figure 1 As shown, this embodiment provides a method for fracturing artificial fractures with low damage and high conductivity in coalbed methane wells, at least including:

[0029] Step 1) prepare the thickener, the thickener includes the following components: by mass percentage, 35% dialkyl sodium sulfosuccinate, 25% octadecyltrimethylammonium chloride, 5% chloride ammonium, 15% ethanol and 20% water;

[0030] Step 2) Use a high-pressure pump set to mix the thickener and water in step 1) at a volume ratio of 1 to 2:100. The thickener already contains clay stabilizers and demulsifiers, which are themselves crosslinking agents After mixing with clean water, the thickening and cross-linking of the water body can be realized to obtain fracturing fluid, and then the fracturing fluid is injected into the formation to create fractures;

[0031] Step 3) In the early and middle stages of the fracture creation stage, the fracturing fluid is continuously injected into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com