Tool with automatic drilling pressure adjustment function

An automatic adjustment and tool technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of difficult to achieve high-efficiency drilling, the effect of improving the drilling speed is not obvious, and the wear of the drill bit is intensified, so as to reduce the collapse of the drill bit The probability of avoiding serious economic losses and the effect of reducing drill bit wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

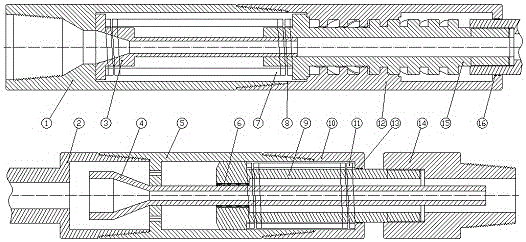

[0008] As shown in the drawings, this tool is composed of connecting parts (upper joint 1, connecting tube 2, lower joint 14), energy storage part (spring inner sleeve 3, multi-strand coil spring 7), helical spline part (inner Helical spline cylinder 12, external helical spline shaft 15), pressurized part (Y-shaped runner sleeve 4, pressurized slide tube 5, pressurized piston shaft 9, combined sealing tube 10, multi-strand coil spring 11) 1. Other components (sealing ring 6, gasket 8, sealing collar 16 and pipe threads everywhere) are composed of five parts. The tool is connected with other drilling tools through the external thread of the lower joint 14 at the lower end of the mandrel and the internal thread of the upper joint 1 . Due to the throttling effect of the Y-shaped flow channel sleeve type 4, a high-pressure zone is formed in the lower cylinder sleeve of the tool, and the lower cavity of the pressurized piston shaft 9 forms a low-pressure zone due to the annular spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com