Double-layer Fire Door Gap Structure and Its Construction Technology

A construction technology and fire door technology, applied in fire doors, windows/doors, building components, etc., can solve the problems of difficulty in cleaning, falling of external impurities, affecting the appearance and overall decoration effect of double-layer fire doors, and reducing cleaning The effect of troublesome, simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

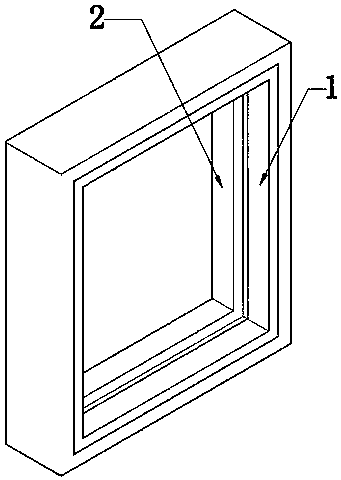

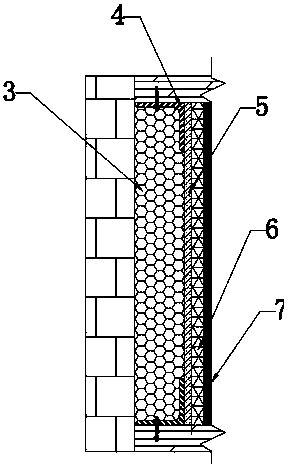

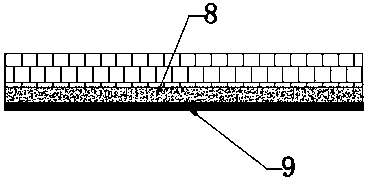

[0032] This embodiment provides a double-layer fire door crack structure and its construction technology. Specifically, the double-layer fire door crack structure includes an outer door frame 1 and an inner door frame 2 (such as figure 1 shown) and the gap layer arranged between the outer door frame 1 and the inner door frame 2, the outer end face of the gap layer is in the same plane as the four door frame end faces of the door frame, and the gap layer consists of vertical interlayers on the left and right sides It is composed of a horizontal interlayer placed between the vertical interlayers. The vertical interlayer is sequentially composed of fireproof cotton 3, gypsum board 5, putty layer 6 and facing layer 7 from the inside to the outside. The upper and lower ends of the fireproof cotton 3 are respectively An L-shaped corner bracket 4 with a bent portion opposite to the wall is fixedly installed; the upper and lower ends of the gypsum board 5 are fixed on the corner bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com