Lock cylinder controlled self-locking anti-theft lock

An anti-theft lock and self-locking technology is applied in the field of anti-theft locks to achieve the effects of improving utilization, strong variability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

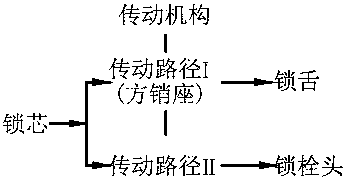

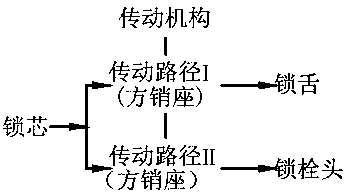

[0030] The self-locking anti-theft lock controlled by the lock cylinder of the present invention mainly includes a lock case, a lock cylinder 41, a lock bolt head, a transmission mechanism and a square pin. The transmission mechanism includes two transmission paths, and the ends of the two transmission paths are connected to the lock cylinder 41 respectively. and latch head. On the transmission path connected with the lock cylinder 41, a square pin seat 1 as a transmission hub is connected, and the square pin and the square pin seat 1 are synchronously rotated and connected.

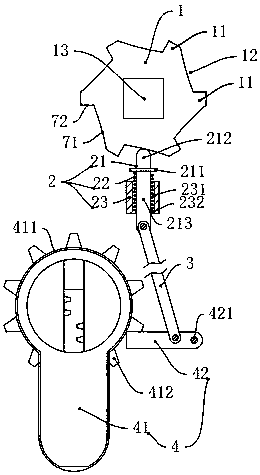

[0031] see image 3 , The self-locking anti-theft lock controlled by the lock cylinder of the present invention also includes a sliding self-locking mechanism 2, a lock cylinder toggle mechanism 4, and a connecting rod 3 that is rotatably connected with the two. In this embodiment, the sliding self-locking part 21 in the sliding self-locking mechanism 2 cooperates with the square pin seat 1 to self-lock...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that in this practical example, the sliding self-locking part 21 in the sliding self-locking mechanism 2 cooperates with the square pin seat 1 to self-lock through magnetic force.

[0043] see Figure 4 , the sliding self-locking mechanism 2 includes a sliding self-locking part 21 and a guide part 23 formed with a guide track 231 . The guide piece 23 is fixedly connected in the lock housing, and the formed vertical guideway 231 points to the rotation axis of the square pin seat 1 . The sliding self-locking part 21 includes a guide hosel 213 located in the guide track 231 and a limiting head 212 protruding out of the guide track 231 .

[0044] The limiting groove 12 is provided on the square pin seat 1 , and the limiting groove 12 includes the groove bottom surface 73 in addition to the above-mentioned anti-rotation surface 71 and transfer surface 72 . The magnet 15 is embedded in the bottom surface 73 of the l...

Embodiment 3

[0050] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in this practical example, the sliding self-locking part 21 in the sliding self-locking mechanism 2 cooperates with the one-way limit rotation of the square pin seat 1 through gravity, and changes the sliding self-locking mechanism. The structural relationship between the lock piece 21 and the square pin seat 1 with one-way limited rotation. At the same time, in this embodiment, a linking rope 5 is used to replace the connecting rod 3 .

[0051] see Figure 5 , the sliding self-locking mechanism 2 includes a sliding self-locking part 21 and a guide part 23 formed with a guide track 231 . The guide piece 23 is fixedly connected in the lock housing, forming a vertical guideway 231 pointing downward to the rotation axis of the square pin seat 1 . The sliding self-locking part 21 includes a guide hosel 213 located in the guide track 231 and a limiting head 212 protruding out of the guide trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com