Bearing apparatus for building wall seam filling

A bearing device and building wall technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of large filling area, unsightly appearance, high strength, etc., and achieves reliable lifting, good filling effect, and reduced labor intensity. Effect

Inactive Publication Date: 2017-05-31

CHENGDU PUJIANG KEXIAN TECH

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Traditional wall gaps are filled manually, but in some places the height exceeds the height of a person. People need to climb up to operate, but climbing up will be dangerous, and it needs to be filled manually, which is tiring. If you need to fill The area is large, the strength is relatively large, and the manual operation, the shape is relatively random, and the appearance may not be beautiful. Therefore, in order to solve these problems, it is necessary to design an automatic filling device.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0025] Embodiment 2: The electric-controlled push rod A can be replaced by an electric-controlled lifting bracket, which can also achieve the effect of lifting and supporting, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

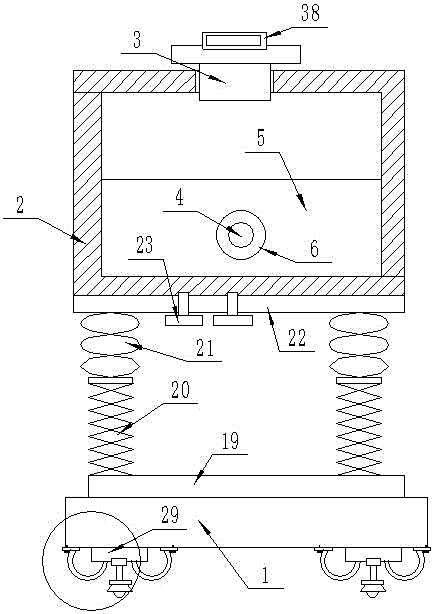

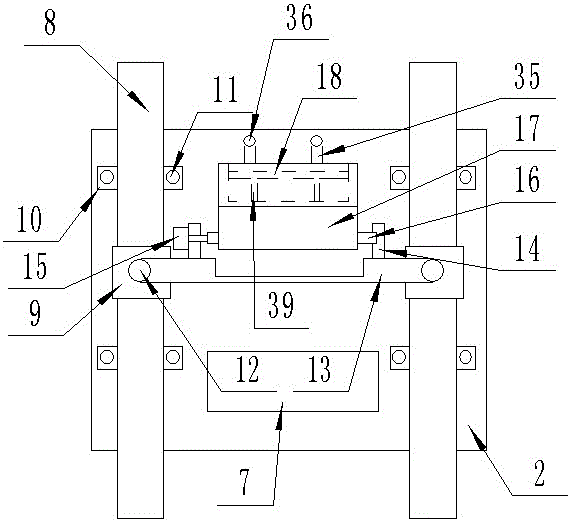

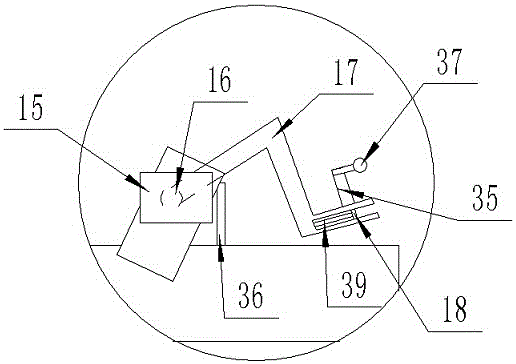

The invention discloses a bearing apparatus for building wall seam filling. The bearing apparatus comprises a rectangular bearing plate. A filler bearing case is arranged over the rectangular bearing plate; an elevating mechanism is arranged between the filler bearing case and the rectangular bearing plate; a wall seam filling mechanism is arranged on the front surface of the filter bearing case; a moving mechanism is arranged on the lower surface of the rectangular bearing plate; a material pushing and discharging mechanism is disposed in the filler bearing case; and a pushing mechanism is mounted on the back side surface of the rectangular bearing plate. The beneficial effects are that the bearing apparatus has great elevating reliability and great filling effect, is easy to push and walk; and labor intensity can be reduced.

Description

technical field [0001] The invention relates to the field of building tools, in particular to a bearing device for filling building wall gaps. Background technique [0002] In construction, there are many tools used. For the wall, due to the relatively large area, the places with wall gaps need to be filled manually to ensure the cleanliness of the wall. [0003] Traditional wall gaps are filled manually, but in some places the height exceeds the height of a person. People need to climb up to operate, but climbing up will be dangerous, and it needs to be filled manually, which is tiring. If you need to fill The area of the filling machine is relatively large, the strength is relatively large, and the manual operation, the shape is relatively random, and the appearance may not be beautiful. Therefore, in order to solve these problems, it is necessary to design an automatic filling device. Contents of the invention [0004] The object of the present invention is to solve ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04G23/02

CPCE04G23/0203

Inventor 陈清尧

Owner CHENGDU PUJIANG KEXIAN TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com