Assembly-type municipal administration integrated pipeline channel and construction method thereof

A comprehensive pipeline and assembly technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of uncoordinated, inconsistent, waste, etc., to reduce costs, avoid re-excavation and damage, and speed up construction fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

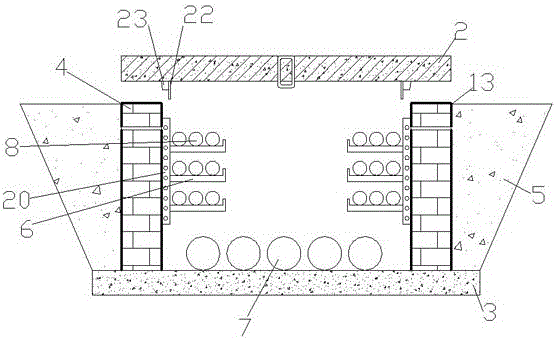

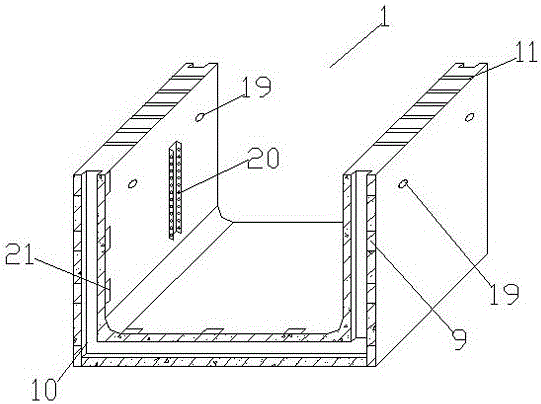

[0038] like figure 1 and 3 As shown in -8, the prefabricated municipal comprehensive pipeline channel of this embodiment 1 includes a prefabricated U-shaped prefabricated plate 1 and a prefabricated cover plate 2, and two water retaining plates 22 are arranged under the prefabricated cover plate 2 to prevent garbage from entering the pipeline The line also prevents rainwater from directly showering the pipeline. One side of the water retaining plate 22 is provided with a positioning plate 23 to prevent the water retaining plate 22 from shifting.

[0039] The assembled U-shaped prefabricated panel 1 includes a plain concrete cushion 3, which is a plane, and the plain concrete cushion 3 is provided with two parallel brick walls 4, and the outer layer of the brick wall 4 is coated with Waterproof cement mortar layer 13.

[0040] A certain space is formed between the two brick walls 4, the outside of the brick walls 4 is provided with backfill soil 5, and the inner wall of the b...

Embodiment 2

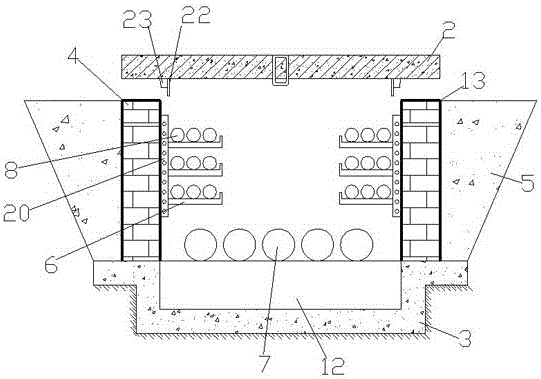

[0045] like figure 2 As shown, the plain concrete cushion 3 in the present embodiment 2 is U-shaped, and the U-shaped cavity is the sedimentation cleaning well 2 .

[0046] Other components and their connections in Embodiment 2 are common knowledge in the art, and will not be repeated here.

[0047] The construction method of the assembled municipal comprehensive pipeline channel of embodiment 1 and 2 comprises the following steps:

[0048] (1) Excavate the foundation trench and slope according to the design requirements;

[0049] (2) The foundation groove shall be leveled, and the waterproof cement mortar bonding layer shall be laid;

[0050] (3) Lift the prepared assembled U-shaped prefabricated pipe into the foundation groove, and weld two adjacent prefabricated pipe components together after they are in place;

[0051] (4) Grouting, pointing, trimming;

[0052] (5) Backfill the seven stones on both sides, tamp them to form backfill soil, and pour the surface layer;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com