Self-rotating clothes washing machine

A self-rotating, washing machine technology, applied in the field of washing machines, to achieve the effect of preventing waste, reducing costs, and smooth rotation of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described now in conjunction with accompanying drawing.

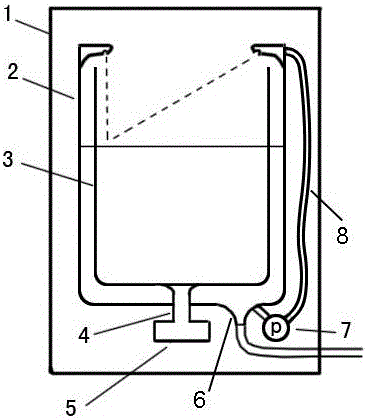

[0038] A jet-type laundry self-rotating washing machine, the jet-type laundry self-rotating washing machine has a casing 1, and the casing 1 has an outer tub 2 arranged longitudinally with an open upper end, and the outer tub 2 is rotatably coaxial A washing drum 3 with an upper end opening is provided. The top of the casing 1 has a clothes inlet and a machine door for closing the clothes inlet. On the upper part of the casing, there is a control device for controlling the operation of the jet type clothes self-rotating washing machine. panel; characterized in that:

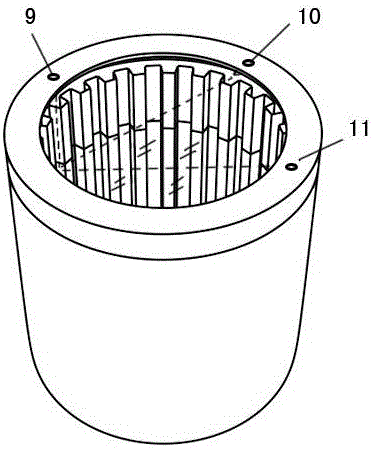

[0039] On the side wall of the washing drum 3, there are longitudinal clothes rubbing lines arranged continuously, and the protruding height of the clothes rubbing lines is between 1 cm and 3 cm, and they are arranged densely along the side wall of the whole washing drum 3. Both the bottom and the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com