Vinyl resin blanking device

A vinyl resin and resin technology, which is applied in the field of vinyl resin feeding devices, can solve the problems of colloidal epoxy resin piled up together and affect the cooling effect, etc., and achieves easy cleaning of impurities, good impurity filtering effect, and fast filtering speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

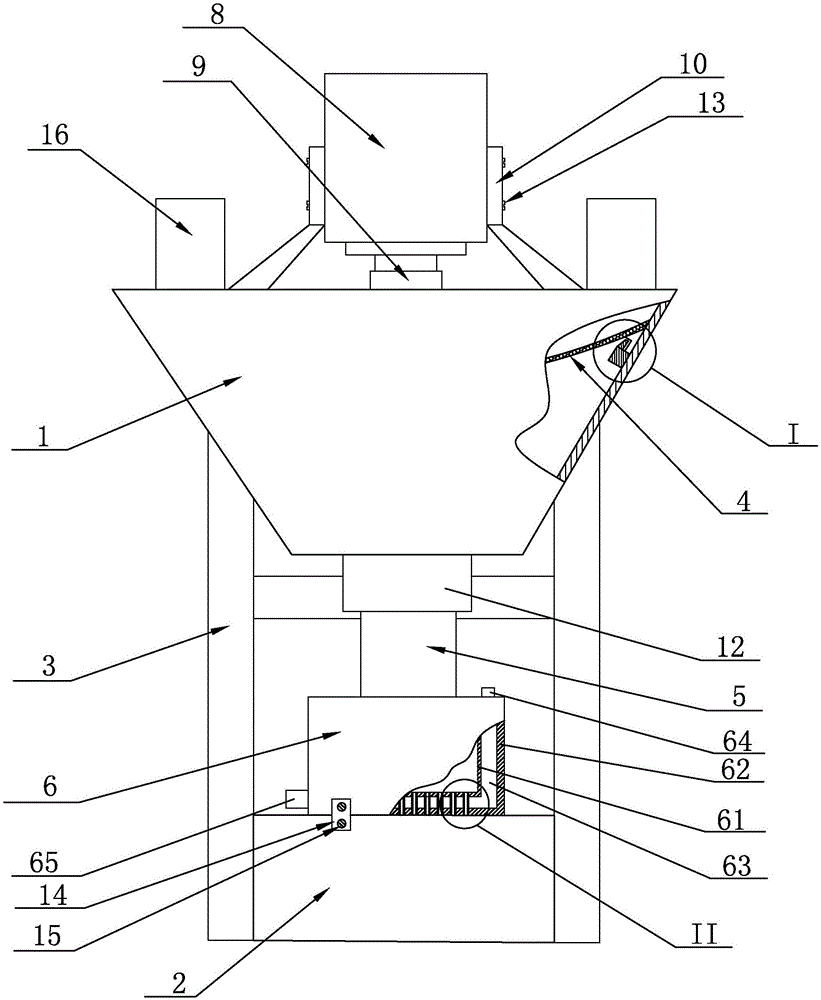

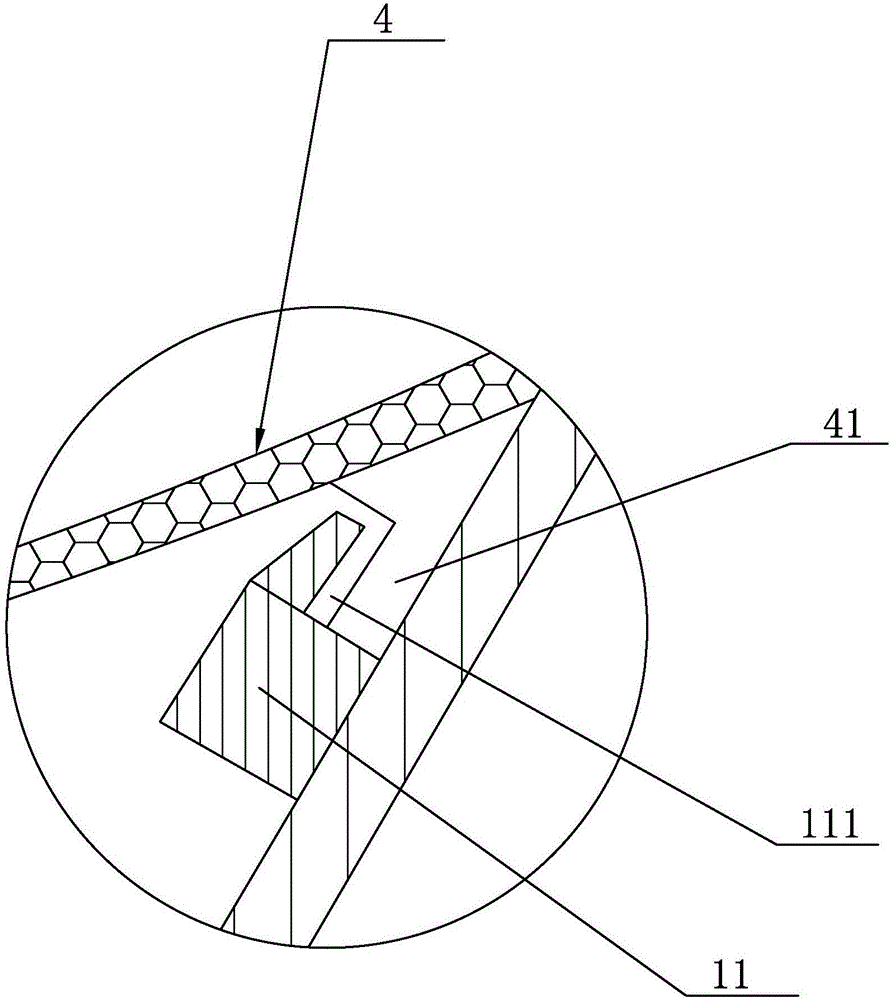

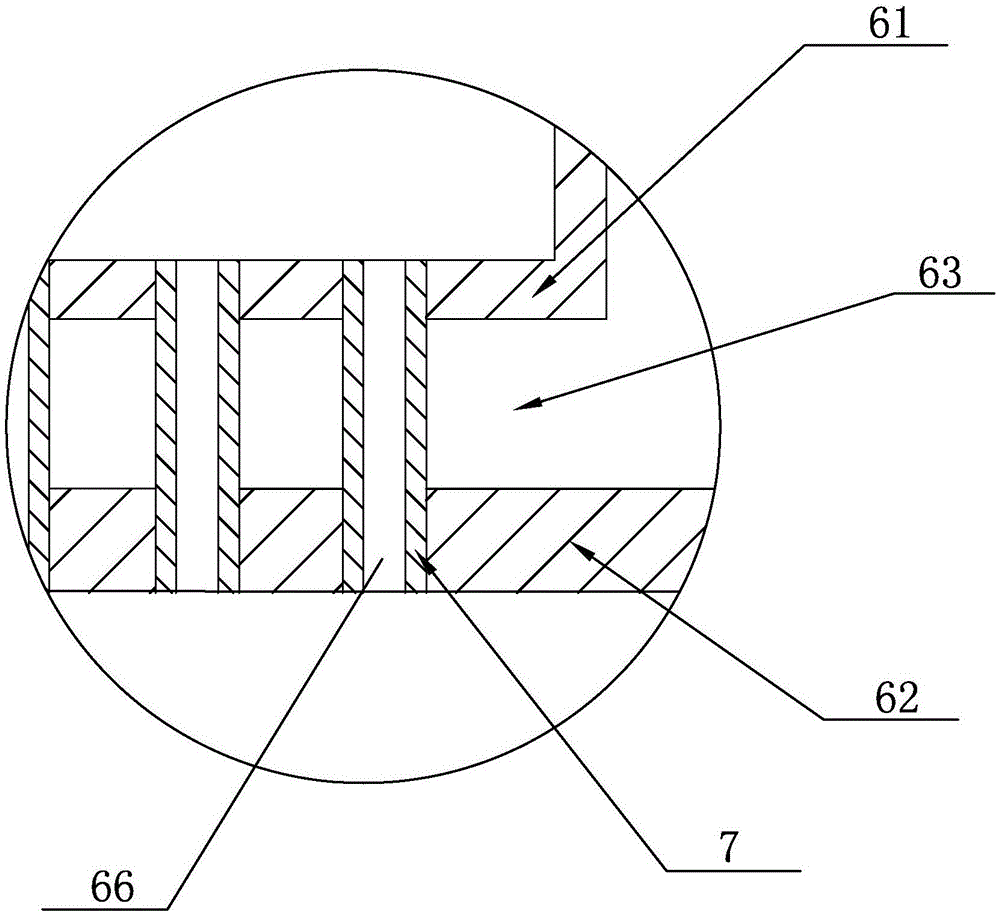

[0020] see figure 1 , figure 2 and image 3 , a vinyl resin blanking device disclosed in the present invention, comprising a hopper 1 and a hopper 2, the lower end of the hopper 1 is fixedly provided with a hopper bracket 3, the hopper 1 is installed above the hopper 2, the hopper 1 The upper end is provided with a filter screen 4, and the upper end of the inner wall of the hopper 1 is integrally provided with a plurality of positioning projections 11, and the upper end of each positioning projection 11 is provided with a slot 111, and the edge position of the bottom surface of the filter screen 4 is integrally provided. There are a plurality of plug-in blocks 41 matching the slots 111, and the filter screen 4 is plugged and fixed with the slots 111 by the plug-in blocks 41; the lower end of the hopper 1 is provided with a discharge port 12, and the discharge port 12 is threadedly connected with a resin feeding pipe 5, and the lower end of the resin feeding pipe 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com