Rotary type feeding and discharging device capable of achieving three-axis transfer

A rotary device and rotary technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of unstable battery clamping, low flexibility, small battery movement space, etc., to shorten the time of loading and unloading and transferring. time, overcoming uneven spacing, and improving the effect of clamping flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

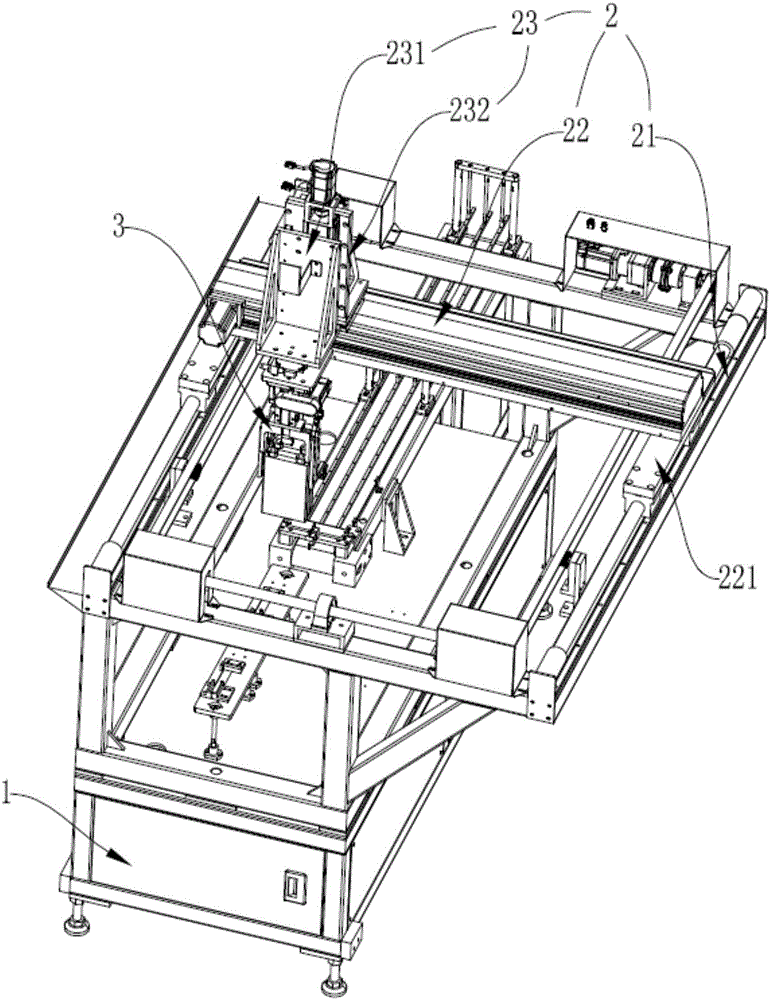

[0028] Such as figure 1 As shown, a rotary loading and unloading device for three-axis transfer, including a frame 1, an XYZ three-axis driving device 2, a clamping device 3 and a rotating device 4; the XYZ three-axis driving device 2 is erected on the machine above the frame 1; the fixed end of the rotating device 4 is connected to the XYZ three-axis driving device 2, and is driven by the XYZ three-axis driving device 2 to move linearly along the X-axis, Y-axis and Z-axis directions; The clamping device 3 is connected to the rotating end of the rotating device 4, and is driven by the rotating device 4 to rotate;

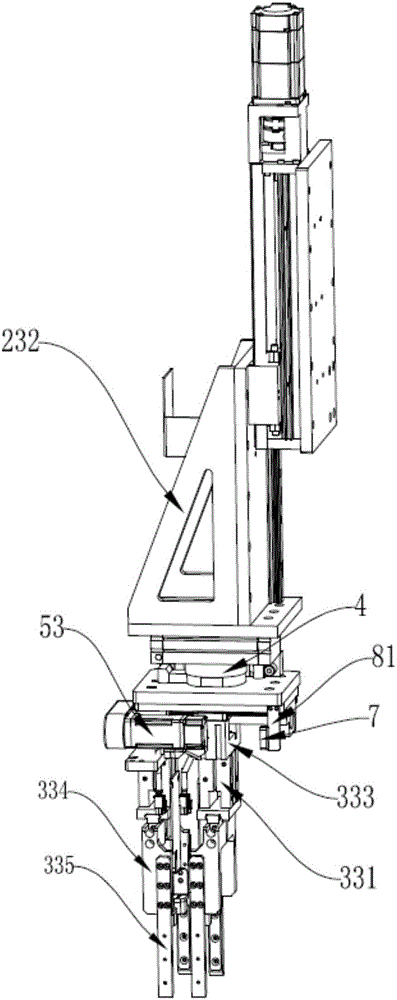

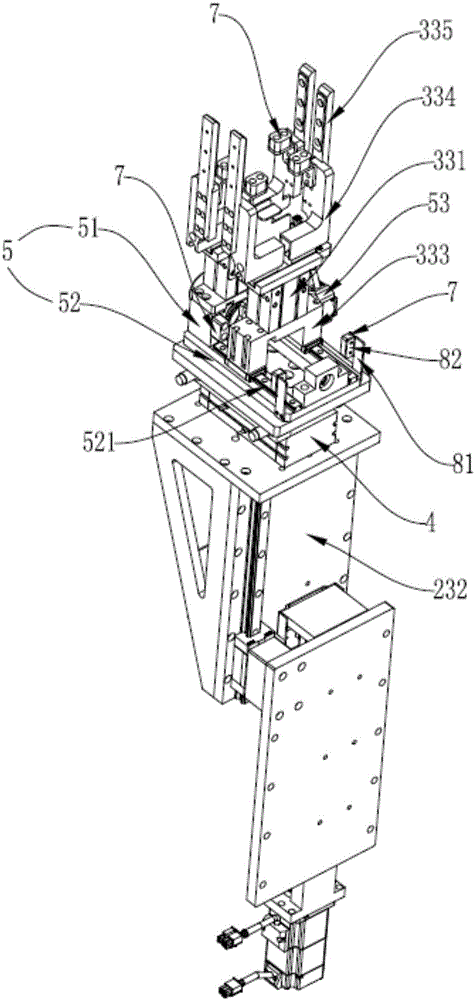

[0029] Such as Figure 4 with Figure 5 As shown, the clamping device 3 is made up of several clamping assemblies 33; each clamping assembly 33 is spaced separately through the spacer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com