Bobbin limit mechanism

A technology of limit mechanism and limit structure, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of not being able to arrange bobbins in the same direction as the size and size, and achieve simple structure, high accuracy, and reduce manual participation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

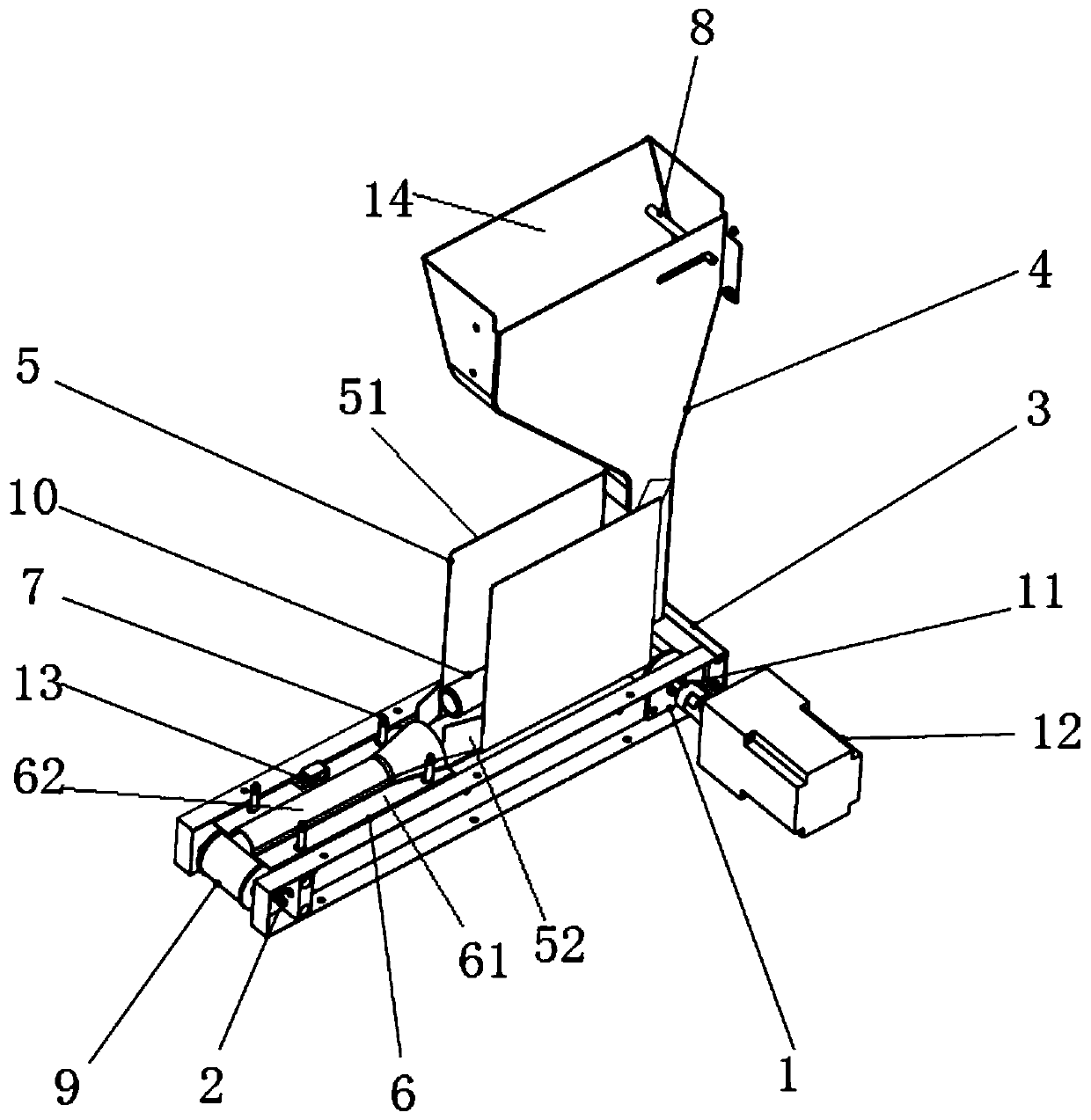

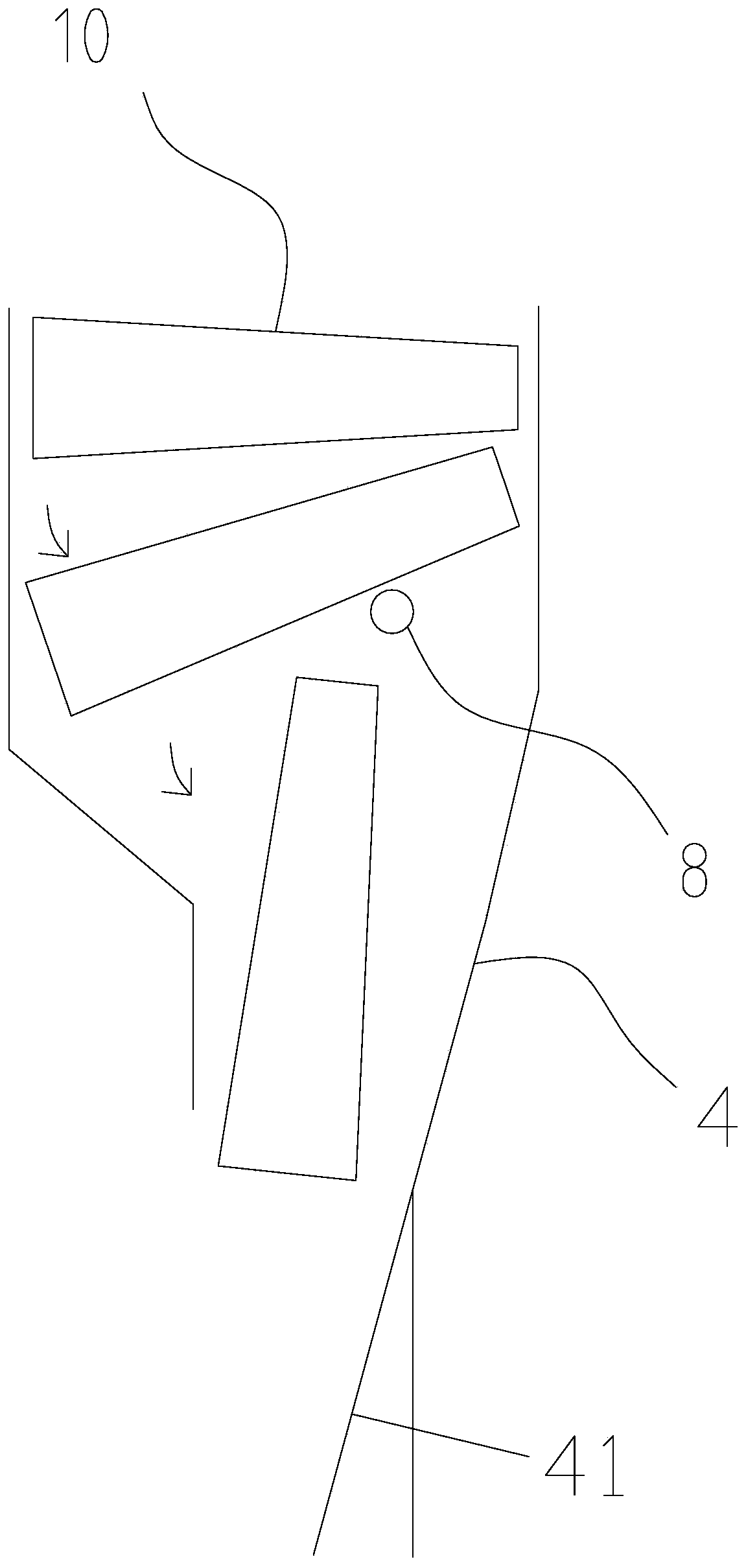

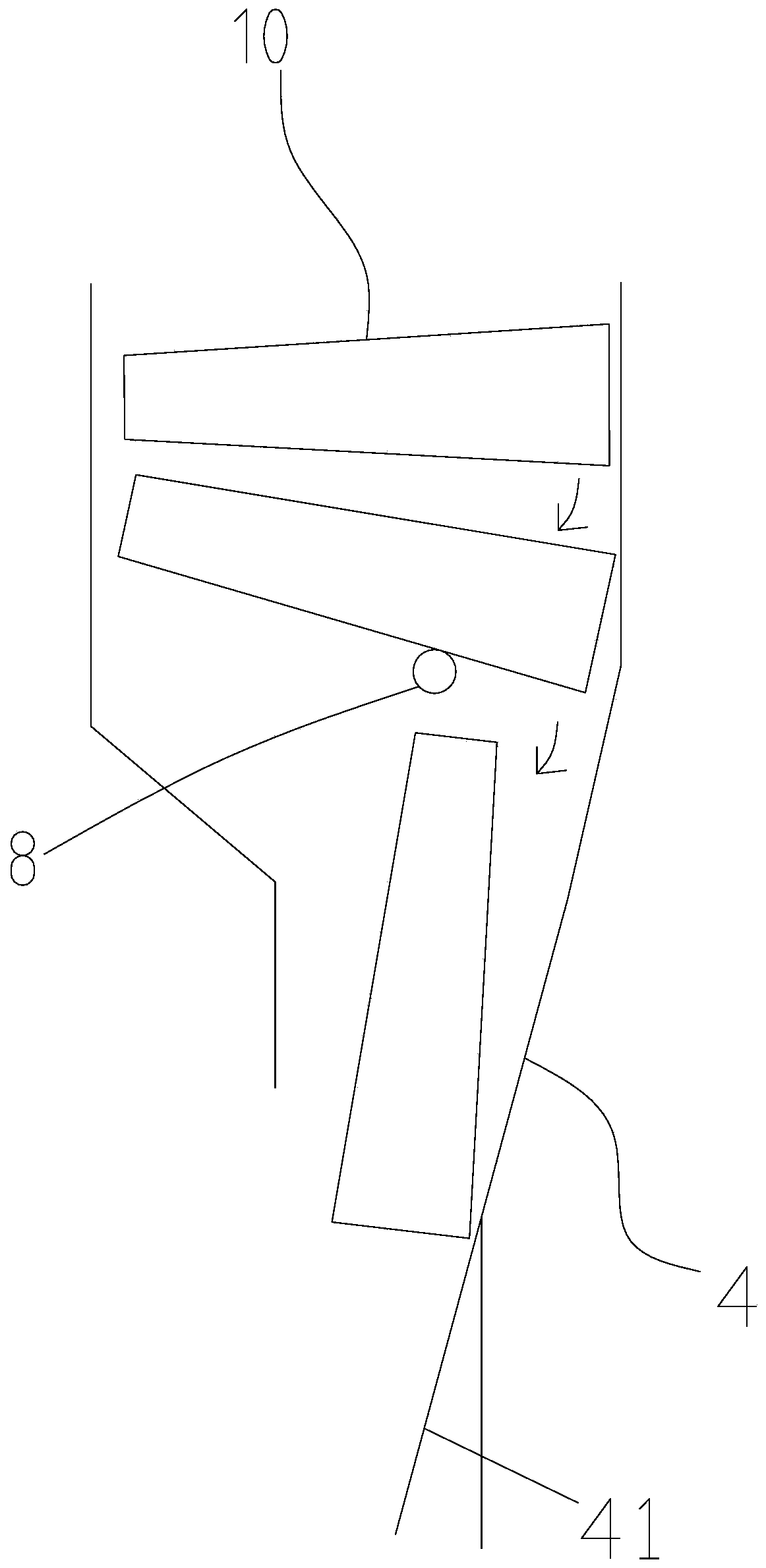

[0021] like figure 1 , a yarn tube limiting mechanism, the diameters of the two ends of the yarn tube 10 are inconsistent, and the two ends are respectively large and small. The limiting mechanism includes a bracket 3, and a hopper is arranged above the bracket 3. There is an inclined surface for the yarn supply bobbin 10 to slide down in the material opening, a yarn bobbin U-turn rod 8 is arranged between the inclined surface and the inner wall of the hopper opposite to the inclined surface, and a yarn bobbin channel 4 is arranged under the hopper to make the yarn bobbin 10 fall vertically. A discharging mechanism is connected below the pipe channel 4 . The feeding port is rectangular, the bobbin channel 4 is located on the side below the feeding port, and the bobbin U-turn lever 8 is located on the side close to the bobbin channel 4 .

[0022] A guide slope 41 for guiding the bobbin 10 to the discharging mechanism is provided below the bobbin channel 4 . The discharge mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com